CNC programming software is widely used in the machinery manufacturing industry, usually including analysis of part patterns, determining the processing process; calculating the tool path to obtain tool position data; writing NC machining programs; making control media; proofreading programs and first piece trial cutting.

Like computer programming, CNC programming also has its own “language”. The difference is that the computer market now takes Microsoft’s Windows as its absolute advantage. None of the numerical control systems has an absolute advantage, which means that the numerical control systems cannot be compatible with each other for a while. Therefore, when we want to use CNC machine tools, we must first know what system the CNC machine tools we already have use.CNC (machining center) is rapidly popularized in the field of machinery, and computer modeling has become a must-learn skill for machinery and mold practitioners. The reality has also proved that a technician who understands graphics and programming will earn much more than his peers with the same technical level. Therefore, it is very necessary for us to understand the relevant knowledge in this area. ASTERCAM, CIMATRON, PRO-E, UG, CATIA, and CAD are commonly used in the CAD/CAM industry.

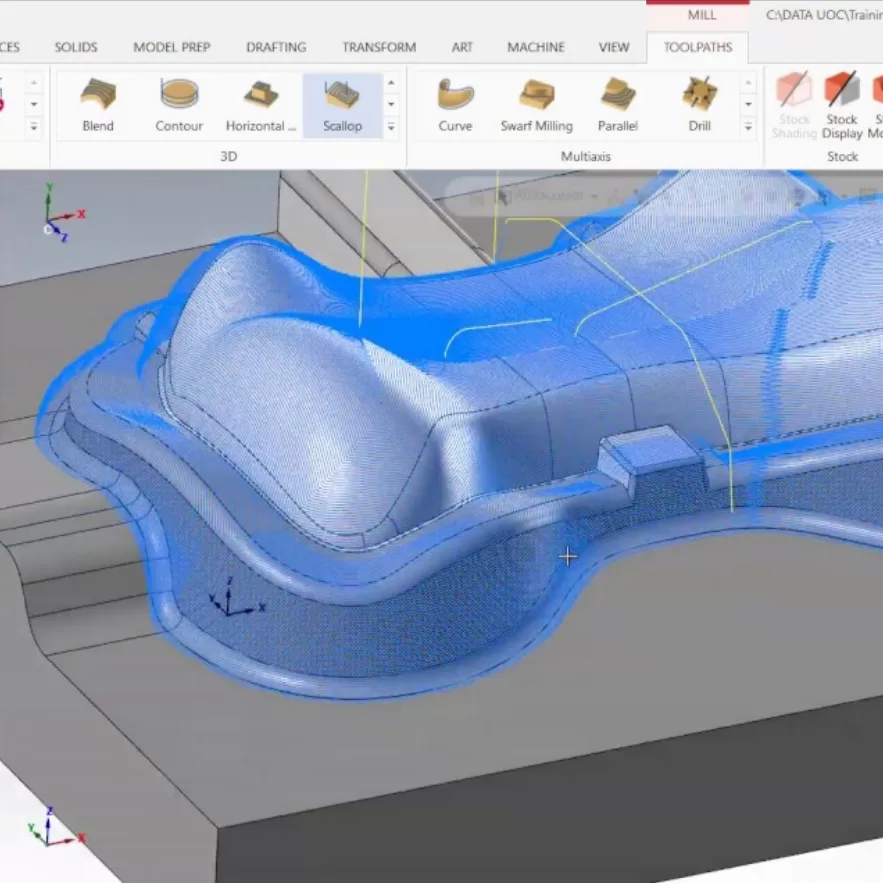

MASTERCAM is the most commonly used CNC drawing software in Guangdong, Shenzhen and other regions of China. It first entered the mainland of China. 70% of the CNC masters in factories use MASTERCAM. It integrates drawing and programming. It draws line structures quickly and has a good zoom function.

CIMATRON is the Israeli military software that entered China later. Its function on the knife path is superior to that of MASTERCAM, making up for the shortcomings of MASTERCAM. The system has been widely used in machinery, electronics, aerospace, scientific research, and mold industries. CIMATRON and MASTERCAM are used in 99% of machining programming. In the early days, these two softwares were used to draw pictures and write NC programs, but their functions in drawing and modeling were not very good. PRO-E walks in at this time Chinese mainland.

Pro/E is a software developed by PTC (Parametric Technology Co., Ltd.) in the United States. It has become the most popular 3D CAD/CAM (computer-aided design and manufacturing) system in the world for more than ten years. Widely used in various industries such as electronics, machinery, molds, industrial design and toys. It integrates multiple functions such as part design, product assembly, mold development, CNC machining, and modeling design. It has been popular in mainland China since 1997. It is used for mold design, product drawing, advertisement design, image processing, lighting design, and can automatically generate engineering drawings. At present, most enterprises have installed Pro/ENGINEER software. Both it and UG are the best drawing software, but PRO-E is more popular in mainland China. Drawing with PRO-E and processing with MASTERCAM and CIMATRON have been recognized.

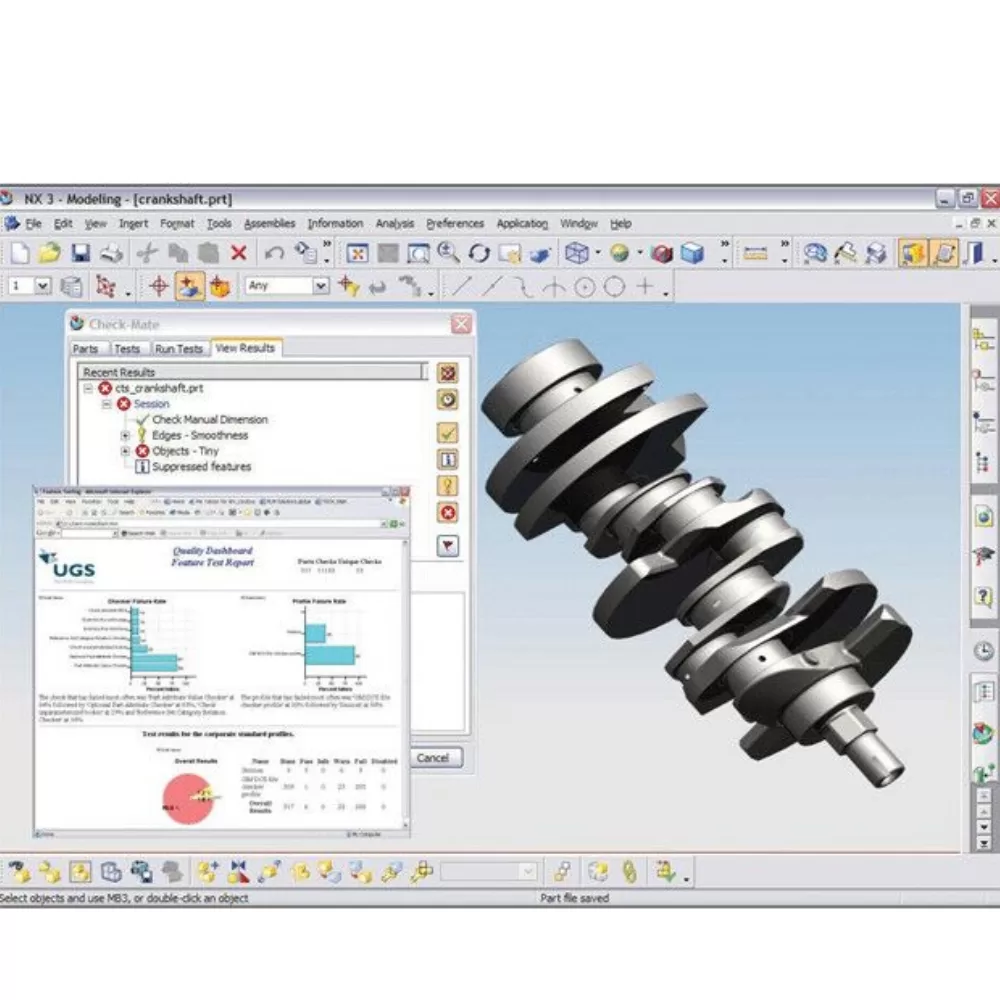

Unigraphics (UG for short) entered mainland China much later than PRO-E, but it is also the most advanced CAD/CAE/CAM high-end software for the manufacturing industry in the world today. UG software is used by many world-leading manufacturers for industrial design , detailed mechanical design and engineering manufacturing and other fields. Today UG has more than 17,000 customers worldwide.

EdgeCAM is an intelligent professional CNC programming software produced by British Pathtrace Company, which can be applied to the programming of CNC machine tools such as turning, milling, and wire cutting. In view of the current processing characteristics of complex 3D curved surfaces, EdgeCAM has designed a more convenient and reliable processing method, which is currently popular in European and American manufacturing industries. British Path Company is developing and operating in the Chinese market, providing more choices for Chinese manufacturing customers.

Catia is a product launched by Dassault of France. It is used in the development and design of legal Mirage series fighter jets, Boeing 737 and 777. CATIA has a powerful surface modeling function, and ranks in the forefront of all CAD 3D software. It is widely used in Chinese aerospace companies and research institutes, gradually replacing UG as the first choice for complex surface design. CATIA has a strong programming ability and can meet the requirements of CNC machining of complex parts. At present, in some fields, CATIA design and modeling, UG programming and processing are adopted, and the two are combined and used together.

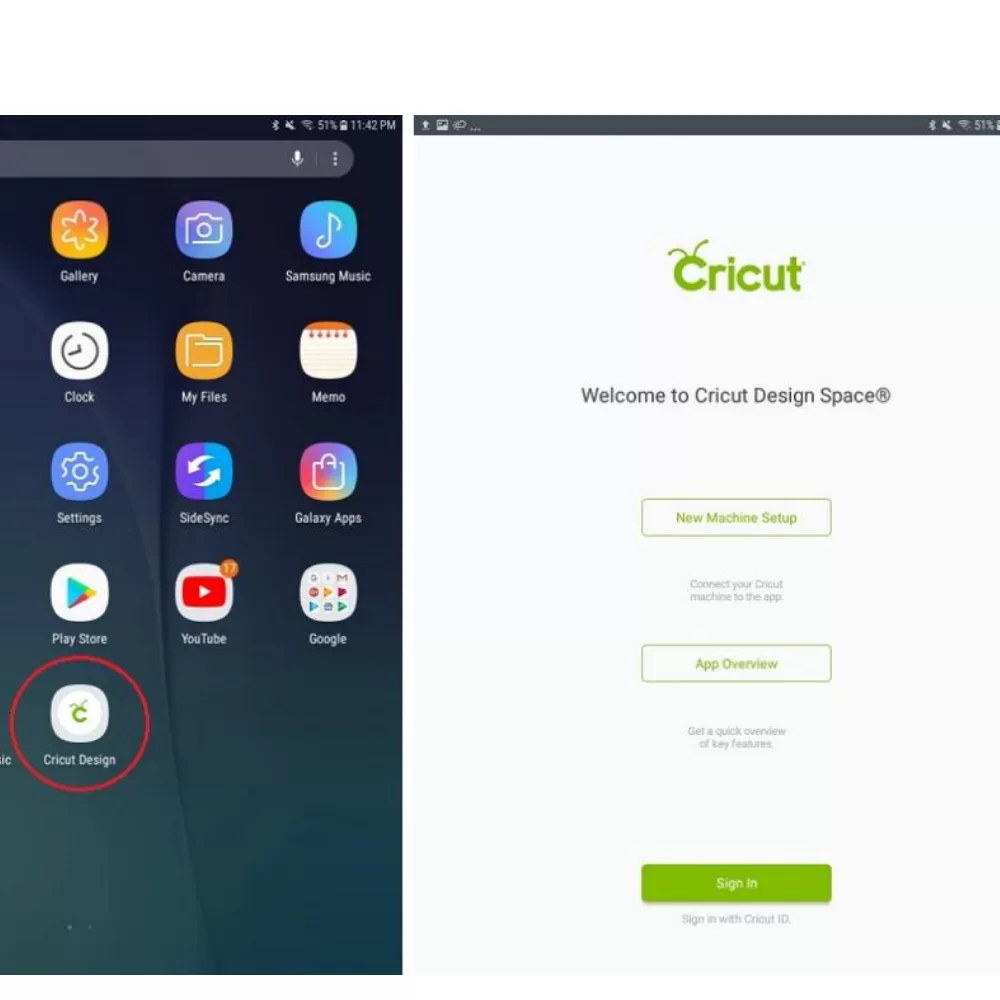

Cricut – An advanced special-purpose NC machining simulation software produced by CGTECH Company of the United States. CRICUT adopts advanced three-dimensional display and virtual reality technology, and the simulation of NC machining process has reached an extremely realistic level. It can not only display the whole process of tool cutting blanks to form parts with colorful three-dimensional images, but also display tool handles, fixtures, and even the operation process of machine tools and the virtual factory environment can also be simulated, the effect is like on the screen Watch videos of CNC machine tools processing parts on the Internet. Programmers import the NC machining programs generated by various programming software into VERICUTVERICUT, and the software performs verification, which can detect calculation errors generated in the original software programming and reduce the rate of machining accidents caused by program errors during machining.

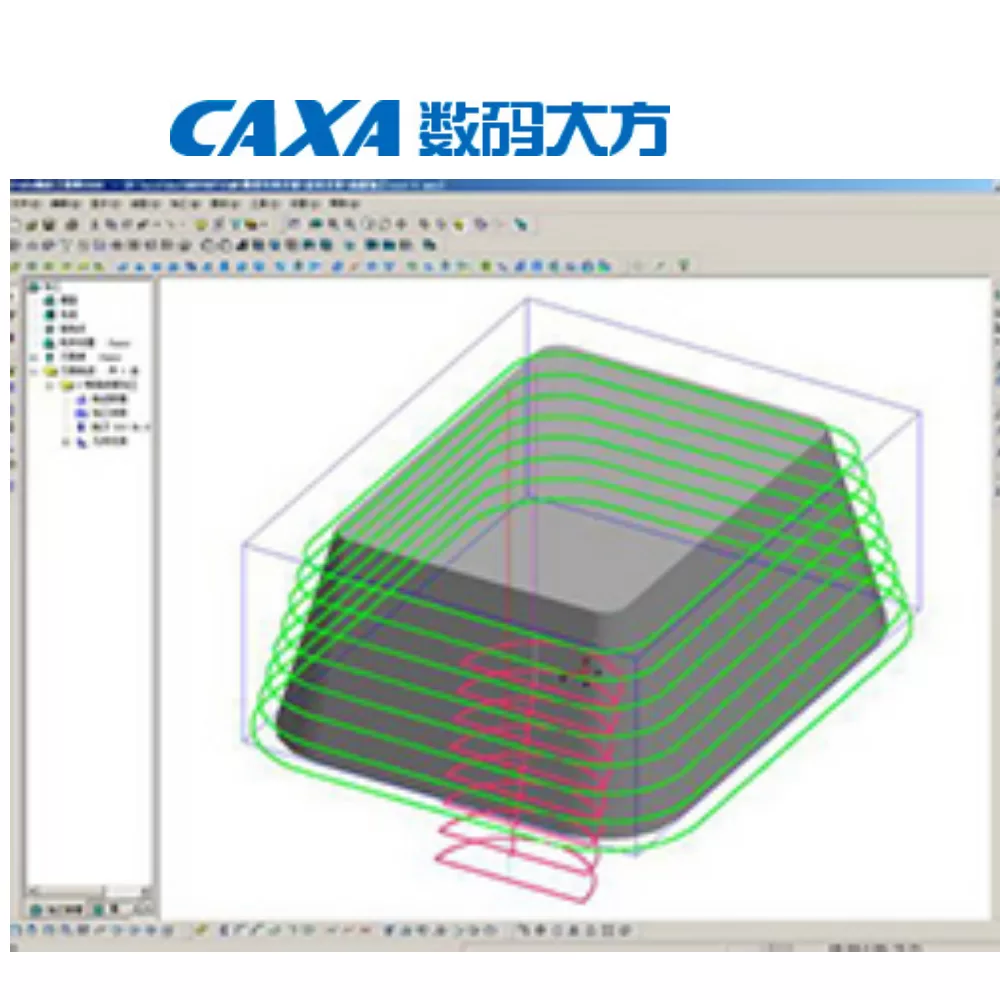

CAXA manufacturing engineer is a nationally produced CAM product launched by Beijing Beihang Haier Software Co., Ltd., which makes domestic CAM software occupy a place in the domestic CAM market. CAXA Manufacturing Engineer is a milling/drilling CNC machining programming software with good process performance for 2- to 5-axis CNC milling machines and machining centers. The software has superior performance and moderate price, and is very popular in the Chinese market.

CNC programming is one of the main contents of the preparation stage of CNC machining, which usually includes analyzing the part pattern to determine the machining process; calculating the tool path to obtain the tool position data; writing CNC machining programs; making control media; cut. There are two methods of manual programming and automatic programming. In short, it is the whole process from part drawing to obtaining CNC machining program. Manual programming means that all stages of programming are done manually. Using general calculation tools, through various trigonometric function calculation methods, manually calculate the tool path and compile instructions. This method is relatively simple, easy to master, and more adaptable. Used for parts that are not molded. For parts with complex geometric shapes, it is necessary to use the computer to use the specified CNC language to write the source program of the part, and generate a processing program after processing, which is called automatic programming.

In the process of CNC machining parts, which of the above 8 commonly used CNC programming and drawing software have you used?