Xi’an Hi-Precision Machinery Co., Ltd. provides you with high-quality and cheap CNC milling services. Whether you need metal or plastic milling, low-volume customization or high-volume production, we will provide you with the most cost-effective CNC milling solution.

Metals that can be used for CNC milling:

A wide range of metal materials are available for CNC milling. Please see the list of materials we use.

If you require alternative materials not listed here, please contact our team to arrange to discuss your requirements.

Select a metal material to see the available options:

Plastic that can be used for CNC milling:

A wide range of plastic materials are available for CNC milling. Please see the list of materials we use.

If you require alternative materials not listed here, please contact our team to arrange to discuss your requirements.

Select a plastic material to see the available options:

QUESTIONS AND ANSWERS ABOUT CNC MILLING

What is CNC milling?

CNC milling generally refers to the process of processing parts on a CNC milling machine. CNC milling machine is a machine tool controlled by a computer and an automated machine tool equipped with a program control system. The control system can perform logical processing on programs with control codes or other symbolic instructions, decode them, express them with coded numbers, and input them into the CNC device through the information carrier. After calculation and processing, the CNC device sends out various control signals to control the movement of the machine tool and automatically process parts according to the shape and size required by the drawing.

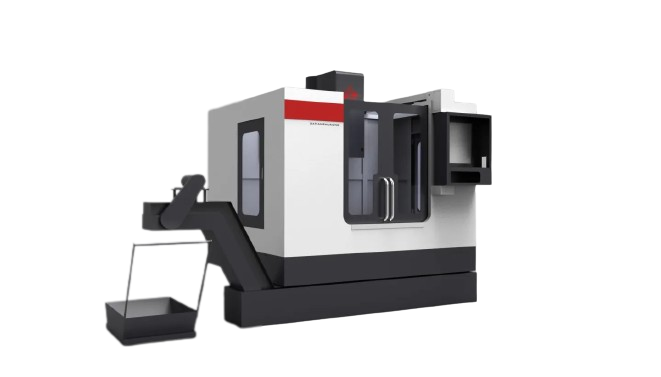

What is a CNC milling machine?

CNC milling machine is an automatic processing equipment developed on the basis of general milling machine. The processing technology of the two is basically the same, and the structure is also somewhat similar. CNC milling machines are divided into two categories: without tool magazine and with tool magazine. Among them, CNC milling machines with tool magazines are also called CNC machining centers.

What is the main difference between CNC milling and CNC turning?

| CNC milling | CNC turning | |

| Cutting Tools | A variety of cutting tools are used, including end mills, face mills and specialty tools, each suited to specific machining tasks. | Primarily single-point cutting tools such as inserts or drills are used. |

| Direction of Movement | CNC milling machines can move along three main axes – X, Y and Z. The X-axis represents horizontal movement from left to right, the Y-axis represents movement from front to back, and the Z-axis represents upward and vertical movement. down. Additionally, CNC milling machines may have fourth and fifth axes for rotational motion of the cutting tool and workpiece, respectively, providing more versatility. | The workpiece rotates on the spindle, while the cutting tool moves linearly along an axis parallel to the workpiece’s axis of rotation (the Z-axis). Some lathes can also allow movement along the X-axis for additional operations. |

| Geometric Constraints | CNC milling can create a variety of complex shapes, including pockets, slots, contours and complex 3D features. Milling can produce parts with different geometries, making it suitable for more complex and customized parts. | CNC turning is ideal for manufacturing cylindrical and symmetrical parts. It specializes in producing parts with circular cross-sections, such as shafts, pins and cylinders. Turning is not ideal for complex shapes with multiple features and irregular geometries. |

| Part Complexity | CNC milling is capable of handling highly complex part designs. It is ideally suited for manufacturing processes with irregular shapes, undercuts and complex parts requiring multi-axis motion. Milling excels at producing custom parts that require precise and varied machining operations. | CNC turning is better suited for relatively simple parts with simple geometries. It is very effective for producing parts that require rotational symmetry and minimal contours. |

| Productivity | CNC milling operations can take longer, especially for parts with complex geometries, due to the need for multiple tool changes, repositioning of the workpiece, and complex cutting paths. | For certain types of parts, especially those with rotational symmetry, CNC turning operations can be faster because the continuous rotation of the workpiece allows for efficient material removal. |

| Material Waste | The CNC milling process creates more scrap, especially when removing excess material from complex shapes, which can result in higher material costs. | CNC turning generally produces less scrap, thus saving material, especially for cylindrical parts. |

What is CNC milling steps?

- Designing the Part: The first step is to design the part to be manufactured using CAD (computer-aided design) software. Designs can also be created from 3D scans of existing parts.

- Convert to CNC code: CAD software converts the design into a set of instructions called CNC code. This code contains the precise coordinates and movements that the milling machine uses to shape the part.

- Machine Setup: The operator sets up the CNC mill by loading the workpiece into the machine and securing it. The operator also loads the CNC code into the machine’s computer.

- Milling Process: After the machine is installed, the milling process begins. According to the CNC code, the machine uses a cutting tool, usually a rotating end mill, to remove material from the workpiece. The cutting tool moves along multiple axes, such as X, Y, and Z, to create the desired shape.