This article will discuss which is more profitable between CNC lathes and CNC milling machines from four aspects. In the first part, we will introduce the definition and principle of CNC lathe, as well as its scope of application in different fields; in the second part, we will introduce the definition and principle of CNC milling machine, as well as its scope of application in different fields; in the third part , we will compare the advantages and disadvantages of these two types of equipment, and explain which type of equipment is more suitable for which industries; in the fourth part, we will analyze the cost-effectiveness of these two types of equipment, comparing their production efficiency, material cost and labor cost. Finally, we will combine the content on CNC lathe VS milling machine: who is more profitable? Make a summary.

1. Definition and application of CNC lathe

CNC lathe is a kind of advanced processing equipment, which can achieve highly accurate processing effect through CNC system. Its main feature is that it does not require human intervention during the processing and is completely controlled by computer programs. CNC lathes are widely used in aerospace, vehicles, military industry, machinery manufacturing and other fields.

CNC lathes have the following characteristics:

- High efficiency: After using CNC programming, the production efficiency can be greatly improved, and the workload and production cost can be reduced.

- High precision: CNC lathes have extremely high running precision and can manufacture high-precision parts.

- Multifunctional: CNC lathes can manufacture complex parts, have the ability to process workpieces of many different shapes, and can process parts of many different materials.

2. Definition and application of CNC milling machine

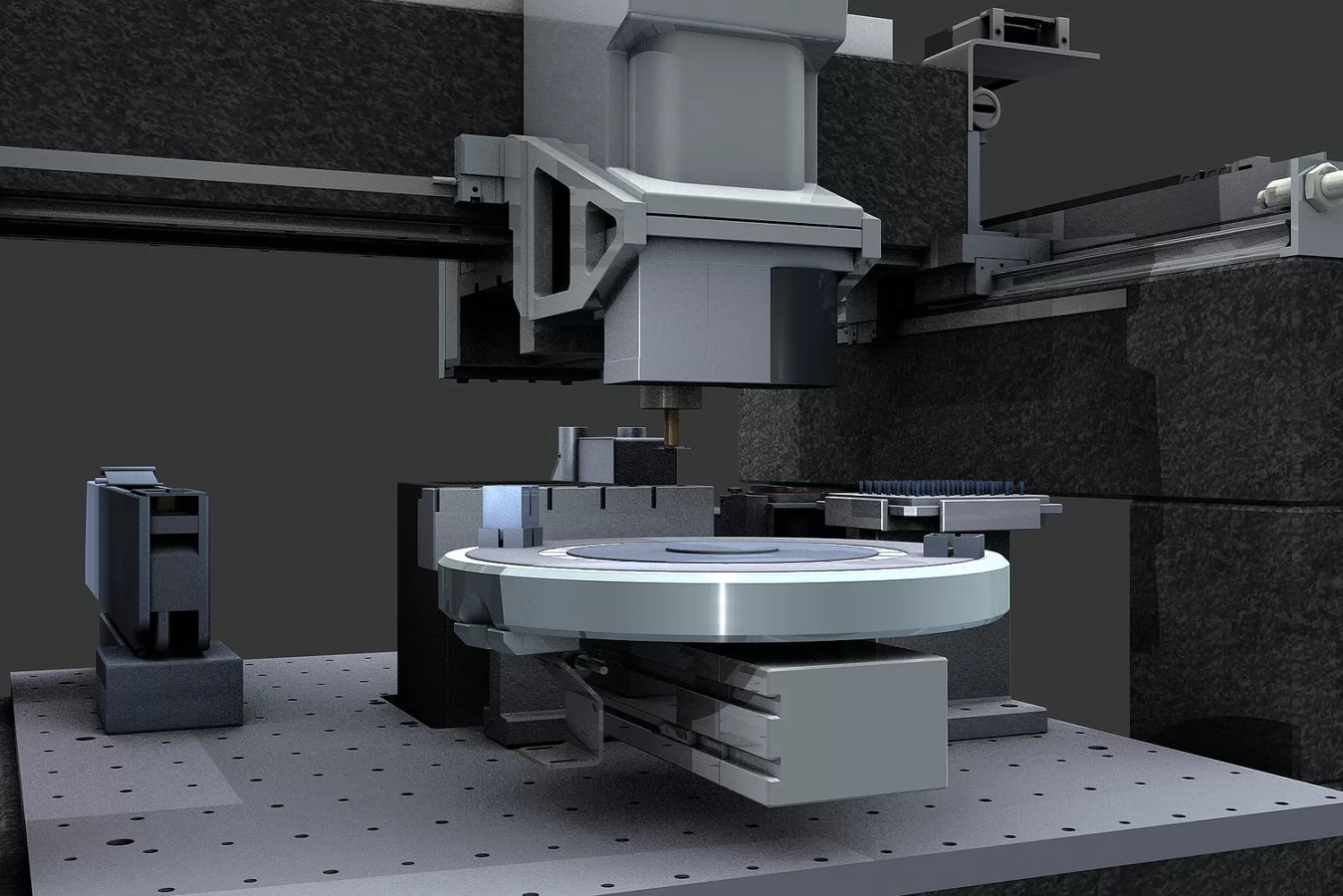

A CNC milling machine is an advanced processing equipment that uses computer programs to achieve high-precision processing results. It utilizes CNC system for automatic control, cutting material and forming required shape. CNC milling machines are widely used in automotive manufacturing, aerospace, electronics and medical equipment manufacturing.

CNC milling machine has the following characteristics:

- High efficiency: After using NC programming, the time for parts processing can be greatly shortened, thereby improving production efficiency.

- High precision: CNC milling machines have extremely high precision and can manufacture complex parts with high precision requirements.

- Versatile: CNC milling machines can process parts of many different shapes and materials.

3. CNC Lathe VS CNC Milling Machine: A Comparison of Pros and Cons

Although both CNC lathes and CNC milling machines are advanced equipment, they have different advantages and disadvantages. The main advantage of the CNC lathe is that it can process workpieces of various shapes such as elongated parts, disc-shaped parts, inner and outer cylindrical parts, etc., especially for workpieces with larger diameters and more difficult processing. CNC lathes have a wider scope of application than CNC milling machines. However, the disadvantage of CNC lathe is that its machining accuracy is greatly affected by material deformation and thermal deformation. The main advantage of CNC milling machine is that it can process workpieces of various shapes, especially for processing complex contour parts. CNC milling machines are not affected by material deformation and thermal deformation during processing, so they can achieve higher processing accuracy. However, the disadvantage of CNC milling machines is that they require larger machine tools and more work space when machining lightweight, large-scale parts. In general, CNC milling machines perform better than CNC lathes in processing parts with high machining accuracy, high surface quality requirements, and complex contours; while CNC lathes are applicable to a wider range. Therefore, the selection of specific CNC machine tools should be comprehensively considered according to the needs of different processed parts, labor costs, and equipment costs.

4.CNC Lathes vs CNC Mills: A Cost-Benefit Analysis

In order to analyze the cost-effectiveness of CNC lathes and CNC milling machines, we will compare them from the following three aspects:

- Production efficiency: For the same kind of parts processing, production efficiency is an important indicator to measure the cost-effectiveness of CNC machine tools. Generally speaking, the production efficiency of CNC milling machine is higher than that of CNC lathe, because the cutting speed of CNC milling machine is faster, and it can adopt multi-axis linkage processing without intermediate manual operation. Therefore, the production efficiency of CNC milling machine is higher than that of CNC lathe.

- Material Cost: Material cost is another important factor when considering cost-effectiveness. For parts processed with the same material, the material waste of the CNC milling machine is less. This is because the CNC milling machine can complete contour processing of various shapes and sizes in one workspace, while the CNC lathe needs to be processed multiple times, and there will be more processing during processing. Big scrap.

- Labor cost: Labor cost has a considerable influence on processing cost. Since the CNC machine tool has the characteristics of automatic processing and does not require manual operation, it is more advantageous in terms of processing costs. However, in terms of equipment operation and maintenance, manpower is still indispensable.

Summary: In terms of material cost and labor cost, CNC milling machines have more advantages than CNC lathes. However, CNC lathes can be applied to machining parts with a wider range of geometric shapes, while CNC milling machines have more obvious advantages in machining accuracy and production efficiency.

Want to buy CNC machine to make money? How to make money if you can’t afford CNC machine? Maybe you can consider CNC machining outsourcing, find a reliable CNC machining factory, hand over your order to the CNC machining factory, and then you make money from the price difference. Xi’an Hi-Precision Machinery Co., Ltd is an on-demand manufacturing CNC machining company that accepts CNC machining orders online and can manufacture products in small or large batches according to your needs. Click contact us at the footer of the website to get cnc machining outsourcing services.