Definition of CNC lathe machining

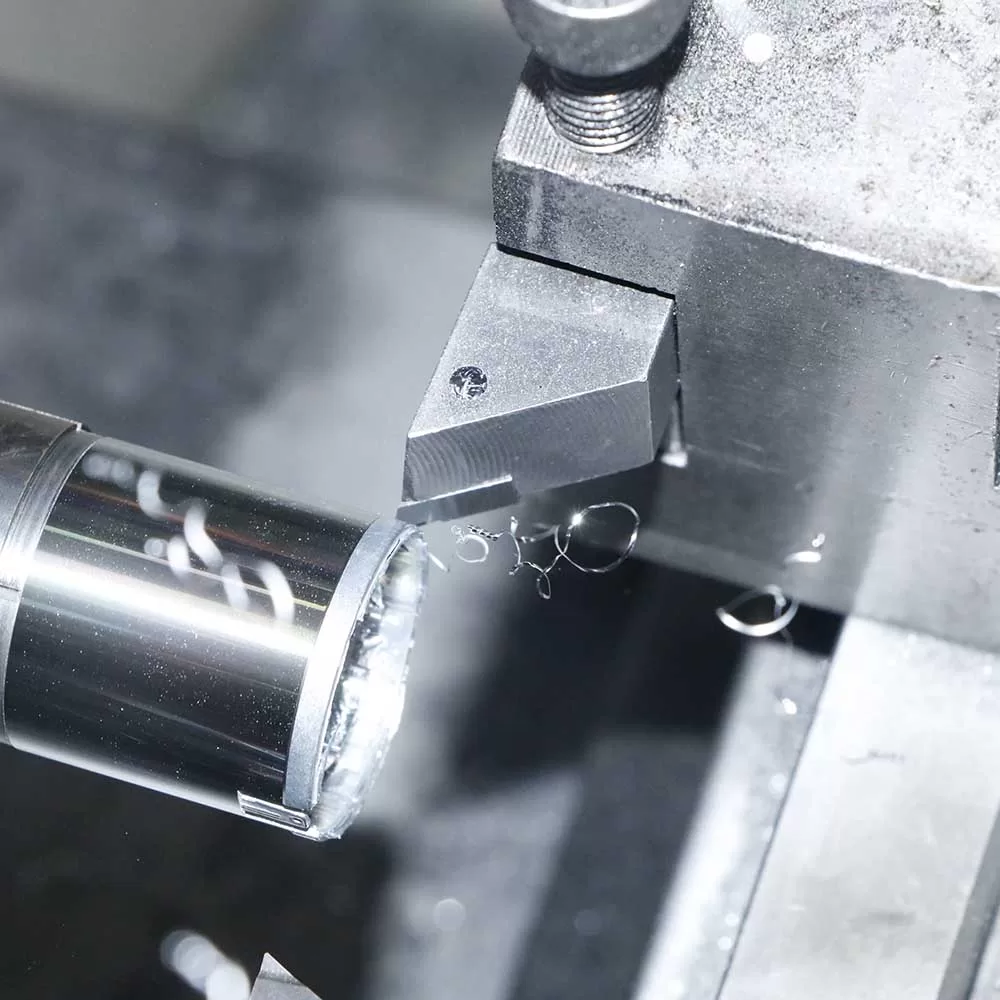

CNC lathe machining is a high-precision, high-efficiency automatic machining that uses digital information to control the displacement of parts and tools. It is an effective way to solve the problems of aerospace product parts such as variable varieties, small batches, complex shapes, and high precision, and to achieve high-efficiency and automatic machining.

In short, CNC lathes are equipment used to complete various cutting machining for mechanical parts.

Materials that can be used for CNC lathe machining

CNC lathe machining is a high-tech machining method for precision hardware parts. Various types of materials can be machined, including 316, 304 stainless steel, carbon steel, alloy steel, alloy aluminum, zinc alloy, titanium alloy, copper, iron, plastic, acrylic, POM, UHWM and other raw materials, which can be machined into square and round combinations parts of complex structures.

Composition of CNC lathe

- The main engine, which is the subject of the CNC machine tool, includes mechanical components such as the machine body, column, spindle, and feed mechanism. It is a mechanical component used to complete various cutting machining.

- The numerical control device is the core of the numerical control machine tool, including hardware (printed circuit board, CRT display, key box, tape reader, etc.) Transformation, interpolation operations and various control functions.

- The driving device is the driving part of the CNC machine tool actuator, including the spindle drive unit, feed unit, spindle motor and feed motor. It realizes the spindle and feed drive through the electric or electro-hydraulic servo system under the control of the numerical control device. When several feeds are linked, the machining of positioning, straight lines, plane curves and space curves can be completed.

- Auxiliary devices, some necessary supporting components of the CNC machine tool, are used to ensure the operation of the CNC machine tool, such as cooling, chip removal, lubrication, lighting, monitoring, etc. It includes hydraulic and pneumatic devices, chip removal devices, exchange tables, CNC turntables and CNC dividing heads, as well as tools and monitoring and testing devices.

- Programming and other auxiliary equipment can be used to program and store parts outside the machine.

There are many parts machining companies on the market, all of which provide CNC lathe machining service. By ordering CNC lathe machining service, you can obtain various customized non-standard parts. CNC lathe machining service are mainly used for cutting machining of inner and outer cylindrical surfaces of shaft parts or disk parts, inner and outer conical surfaces of arbitrary cone angles, complex rotary inner and outer curved surfaces, cylinders, and conical threads, etc., and can perform grooving, drilling, expanding Holes, reaming and boring etc. Want small batch CNC lathe machining services? Contact us now.