Producing a bicycle frame usually requires multiple processes such as molding, machining, and assembly. But 5-axis CNC milling has revolutionized this production method. Will CNC milling bicycle frames be the mainstream bicycle frame manufacturing process in the future? So let’s start by taking a look at the frame of this mountain bike that is built entirely on a 5-axis CNC machining center!

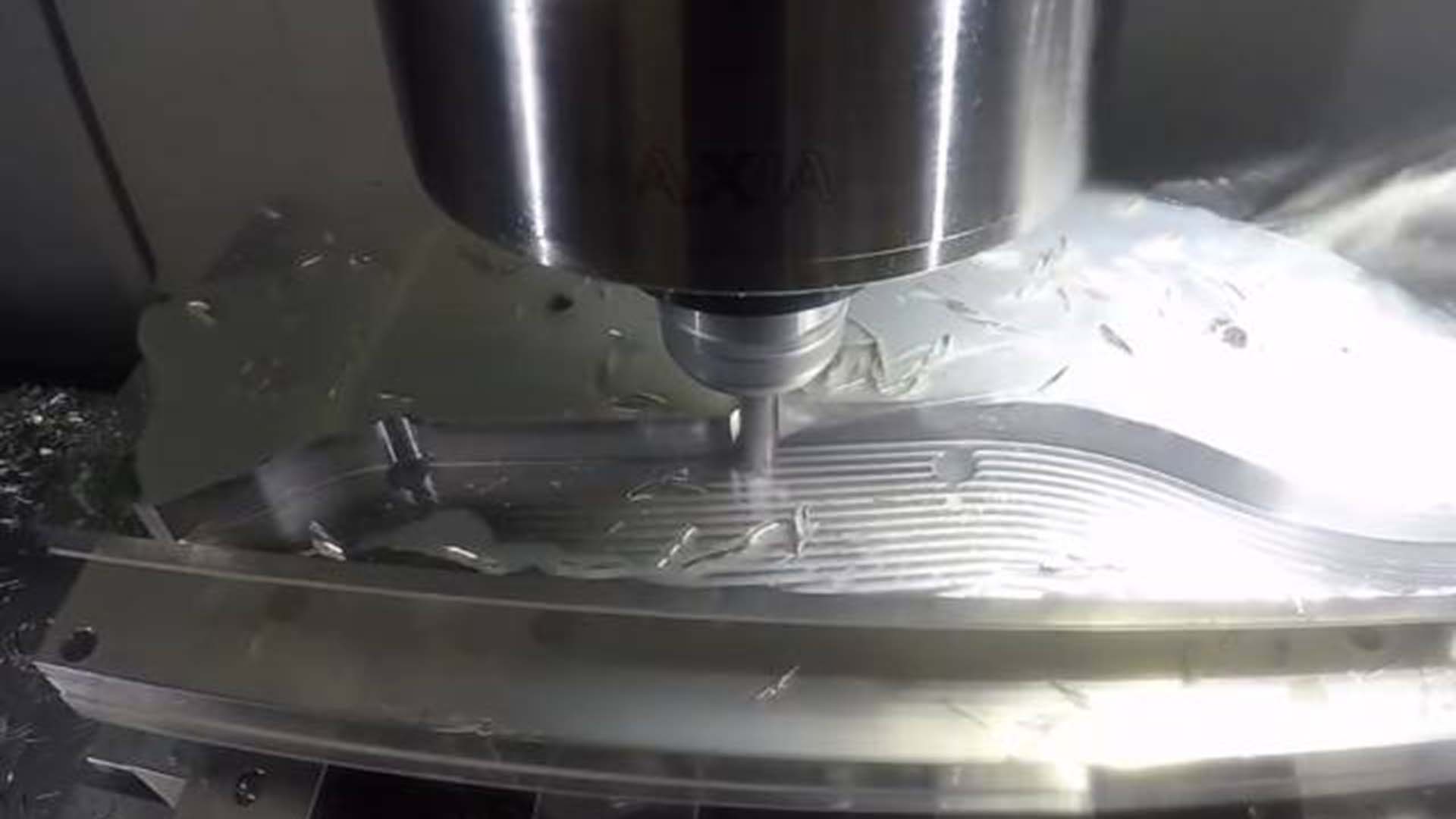

From the picture above we can see that the frame of this mountain bike is made of aluminum alloy. Milling aluminum parts on a 5-axis CNC machine is the best way to create ultra-precise and complex aluminum parts. Aluminum alloy has low density, but relatively high strength, close to or exceeding high-quality steel. It has good plasticity, good machining performance, and excellent corrosion resistance. Its usage is second only to steel. It is a very suitable material for bicycle frames.

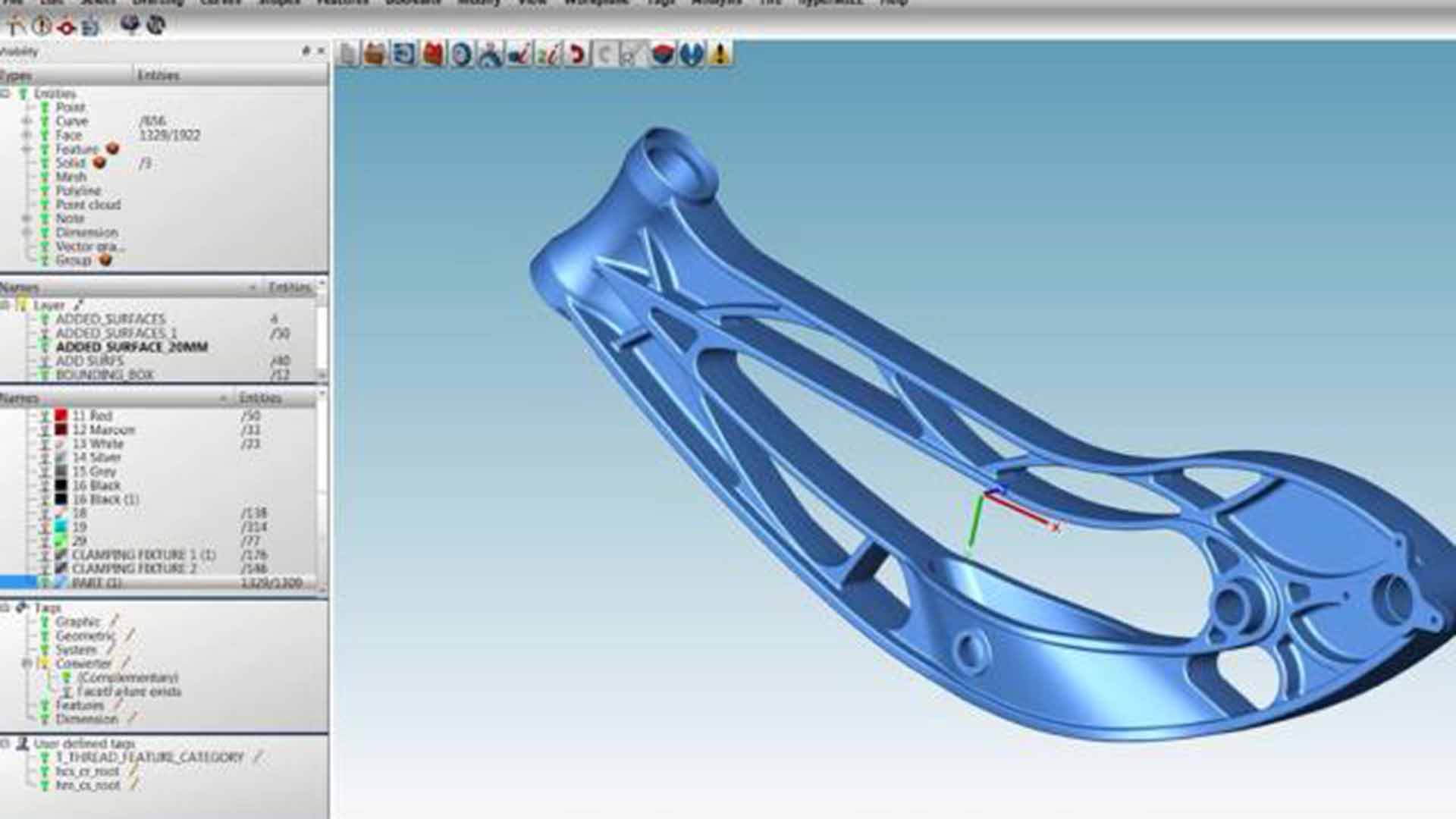

It’s not easy to machine and shape a bicycle frame in one go, but we did it. Because we have advanced 5-axis CNC milling machines and a strong team. We use CAM software for pre-programming, and then place the entire piece of aluminum on a CNC machine for milling. Our team has extensive hands-on experience in 5-axis CNC machining, which is extremely advantageous in manufacturing a unique weld-free ultra-light alpine downhill mountain bike frame. It only took one and a half hours to CNC milling bicycle frame from a piece of aluminum weighing 165 kilograms to a frame weighing no more than 7 kilograms.

Five axes refers to the three moving axes of x, y, and z plus any two rotation axes. Compared with the common three-axis (x, y, z three degrees of freedom) machining, five-axis machining means that when processing parts with relatively complex geometric shapes, the machining tool needs to be able to position and connect in five degrees of freedom. The machine tools used in five-axis machining are often called five-axis machine tools or five-axis machining centers.

The method of using 5-axis CNC milling of bicycle frames can indeed improve the efficiency and quality of mass production of bicycle frames, but it also increases the overall manufacturing cost of bicycles. Therefore this method is only suitable for the manufacturing of high-end brand bicycles. If you need to mass-produce weld-free ultra-light bicycle frames, please consider our 5-axis CNC machining process.