In the field of industrial manufacturing, prototypes must be used to express product design concepts. Methods for manufacturing industrial prototypes generally include: 3D printing, CNC machining, rapid prototyping, etc. So, which is the cheapest way to create a prototype?

To Achieve Cheap Prototyping, Consider the Following 2 Methods:

- DIY prototype. Do-it-yourself prototyping is the cheapest way. You can use available low-cost materials such as cardboard, plastic, foam board, etc. to create prototypes through hand processing and assembly. This method is cheaper because you don’t have to commission an outside supplier, which saves you the most money on prototyping.

- Entrust external suppliers or manufacturers. Although seeking third-party assistance will greatly increase the cost of prototype manufacturing, it can save you a lot of unnecessary trouble. Many companies on the market can provide cheap prototyping services. They usually use 3D printing, CNC cutting, rapid prototyping and other methods to manufacture prototypes.

The prototypes involved in the industrial manufacturing field are usually complex and precise, so they are not suitable for DIY prototype manufacturing. Therefore, cooperation with external suppliers has become an inevitable choice for many small and medium-sized enterprises and individuals. So in this case, how to create a prototype at the cheapest price?

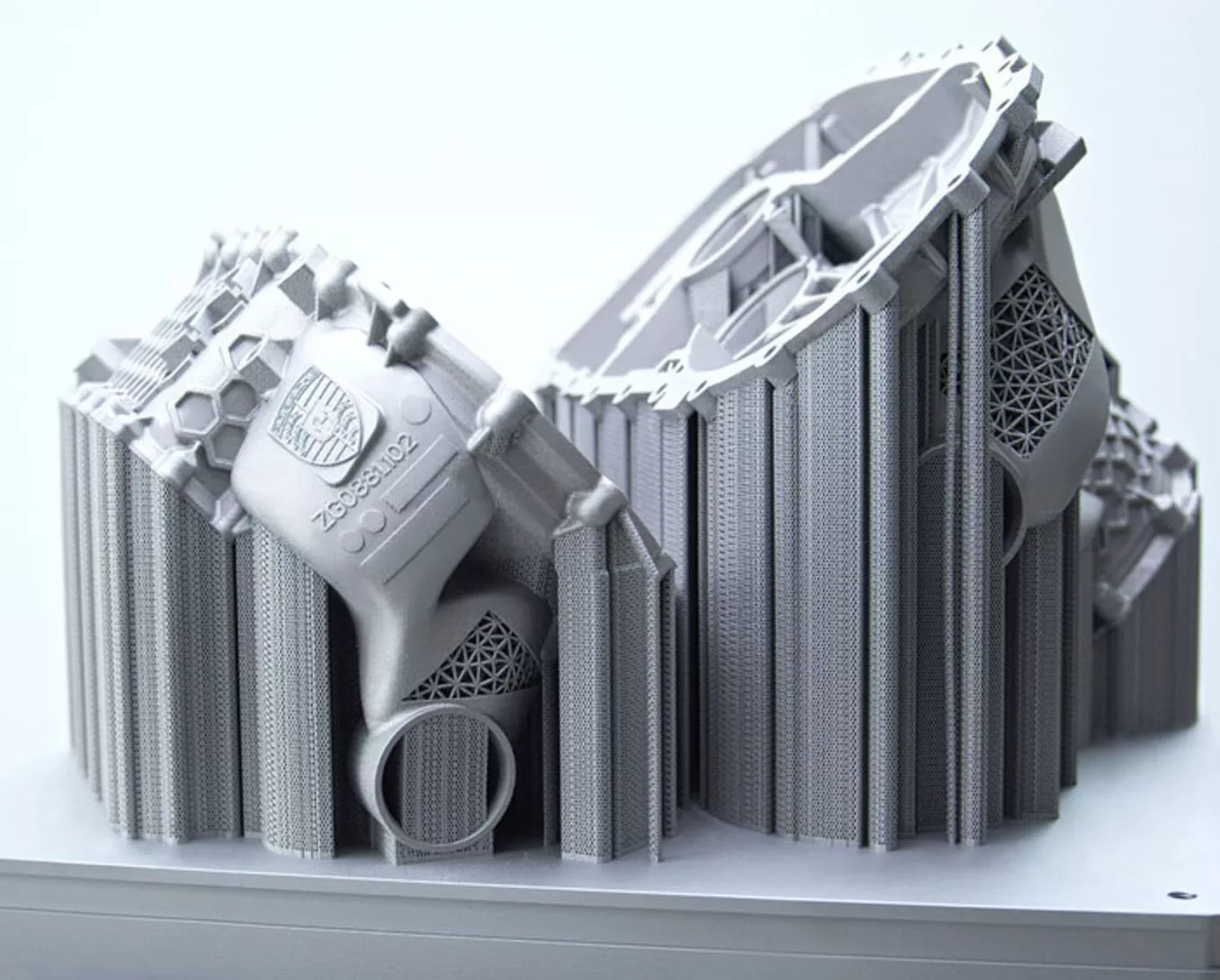

3D printed prototype. Compared with traditional manufacturing methods, 3D printing can quickly produce prototypes. It eliminates the need to manufacture molds or tooling, converting design files directly into physical objects. 3D printing can also realize the manufacturing of complex shapes and structures, with a high degree of design freedom. This enables designers to better explore innovative designs and verify their feasibility. 3D printing can be customized and manufactured according to needs. For each prototype, parameters and materials can be adjusted according to specific requirements to meet specific design needs. 3D printing is an additive manufacturing technology that manufactures objects by stacking materials layer by layer, so it does not produce a large amount of leftover material and reduces material waste. Due to the rapid manufacturing characteristics of 3D printing, prototype iteration, rapid modification and re-manufacturing can be easily carried out, saving time and costs. Although the variety of 3D printing materials continues to increase, the available materials are still limited compared to traditional manufacturing methods. Some special materials may not be suitable for 3D printing technology. The accuracy and surface quality of 3D printed prototypes are often inferior to traditional manufacturing methods. Especially for demanding applications or fine details, further post-processing processes may be required to improve quality. Although 3D printing can provide some cost savings in prototyping, the cost is still higher for high-volume production. Material expenses, equipment investment and maintenance all need to be considered as cost factors. Therefore, if you are considering 3D printing for prototyping, you may go over your budget.

CNC machining prototype. CNC machining can achieve high manufacturing accuracy and is especially suitable for prototype manufacturing that requires precise dimensions and geometries. Can adapt to a variety of materials including metal, plastic, wood, etc. Material requirements that can meet different needs. CNC equipment usually has a large operating space and is suitable for manufacturing small to medium-sized to large prototypes. CNC manufacturing enables complex geometric structures and curved shapes, allowing designers to transform innovative design ideas into actual prototypes. Compared with other prototype manufacturing technologies, CNC manufacturing is suitable for mass production and can produce multiple identical or similar prototypes in a shorter period of time. CNC machine tools can be controlled by computer programs to achieve automated operation and improve production efficiency and stability. CNC equipment typically requires a higher initial investment. The cost of purchasing and maintaining equipment is high and may not be appropriate for individuals or small organizations. CNC machining requires the use of CAD software to create precise design files and convert them into instruction codes suitable for processing equipment. This may be a challenge for some without relevant skills and experience. CNC machined prototypes will produce machining marks and surface roughness, and may require further machining and surface treatment to achieve the required quality requirements. But in general, if sophisticated and complex industrial prototypes need to be manufactured in batches, CNC machining is usually the cheapest prototype manufacturing method.

Open source hardware and software. Consider using virtual prototyping or simulation software tools instead of actual prototyping. Leverage open source hardware and software resources to reduce R&D costs. Many open source projects provide cheap prototyping solutions, such as Arduino, Raspberry Pi, etc.

Generally speaking, if you want to create a prototype in the cheapest way, you have to DIY it yourself. DIY has no restrictions on professional qualifications. You can do whatever you want. Everyone can use DIY to make a privately customized “prototype” to express themselves.