Hi-Precision provides CNC lathe processing services for various industries around the world. With advanced CNC lathe equipment and rich turning experience, a wide range of material selection and strict quality control, we are confident to manufacture a variety of simple or complex non-standard parts for you. Contact us now to get manufacturability feedback.

Quickly Understand CNC Lathe Machining

What is CNC lathe machining

CNC lathe machining is a technology that uses computer numerical control systems to control lathes for precision machining. It is widely used in the manufacturing of various cylindrical parts, such as shafts, pipes, threads, and other complex shaped parts.

Basic principles of CNC lathe machining

A CNC lathe uses a computer control system (CNC controller) to interpret pre written programs (usually G-code) and control the movement and operation of the lathe. The program includes machining parameters such as tool path, feed rate, and cutting depth.

The process of CNC lathe machining

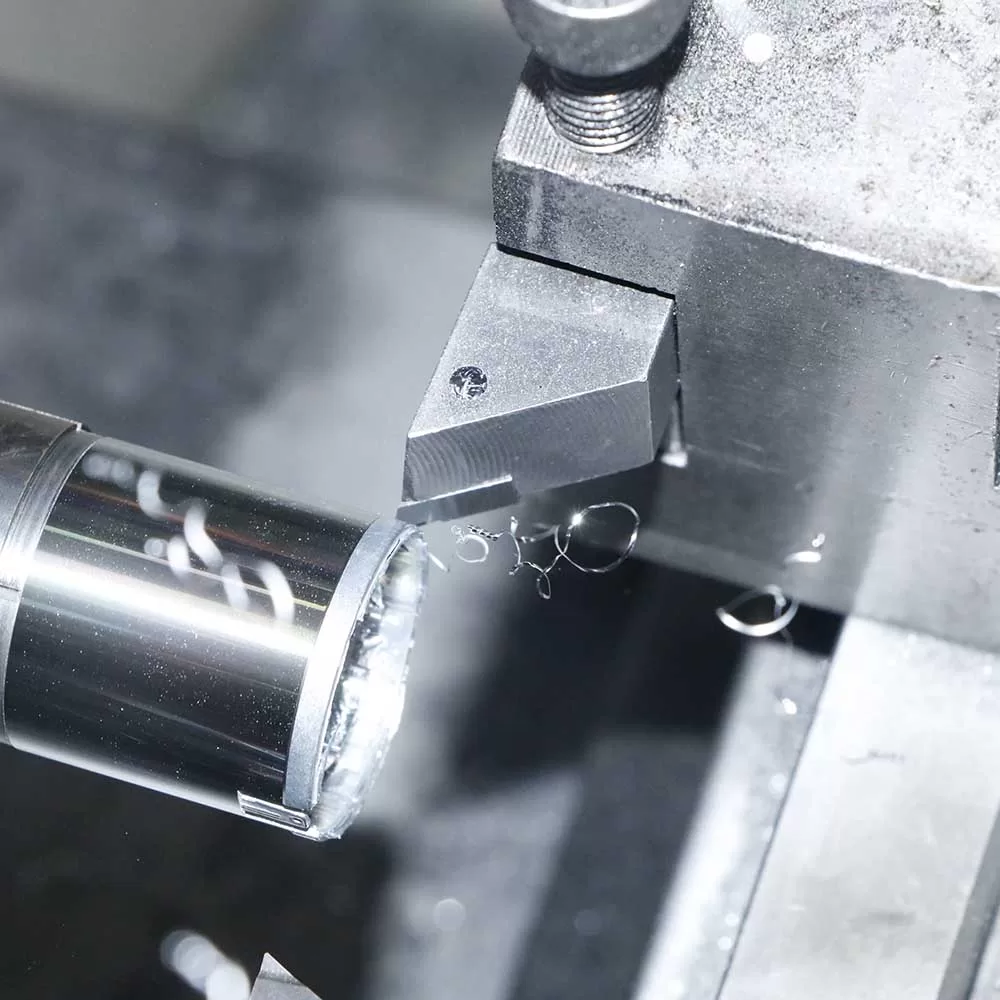

Turning: mainly used for machining cylindrical parts, cutting by rotating the workpiece and fixing the cutting tool.

Drilling: Drill holes of various sizes and depths on the workpiece.

Thread processing: Processing internal and external threads, suitable for parts such as bolts and nuts.

Boring: Precision machining of existing holes to improve their dimensional accuracy and surface quality.

Groove cutting and cutting: Cutting grooves or cutting workpieces on the workpiece.

The advantages of CNC lathe machining

High precision and consistency: CNC lathes can achieve extremely high machining accuracy, ensuring that each part meets strict tolerance requirements.

High efficiency and productivity: CNC lathes can process quickly and efficiently, making them suitable for large-scale production.

Flexibility and customization: CNC lathes can be programmed according to different processing requirements to adapt to the processing of various complex shapes and sizes of parts.

Reduce waste and save costs: Accurate processing reduces material waste and improves material utilization.

Automation and efficient production: Automated processing reduces reliance on manual operations and improves production efficiency.

Application of CNC lathe machining

Automotive components: axles, gears, bearings, driveshafts, engine parts, etc.

Aerospace: high-precision parts such as turbine shafts and aircraft landing gear components.

Medical devices: high-precision medical parts such as orthopedic implants and surgical instruments.

Electronic products: connectors, casings, heat sinks, etc.

Industrial equipment: pump shafts, valves, pipeline joints, etc.

The main components of a CNC lathe

CNC controller: responsible for interpreting G-code and controlling the movement of the lathe.

Spindle: used for fixing and rotating workpieces.

Knife holder: used for installing and replacing cutting tools.

Bed: Provides a stable machining platform.

Tail seat: used to support the other end of a long workpiece.

Feed system: controls the feed motion of the tool.

The steps of CNC lathe machining

Design and programming: Use CAD software to design the 3D model of the part, and use CAM software to generate the machining program (G code).

Setup and debugging: Install the tool and workpiece, set the zero point and machining parameters, perform trial machining and debugging, and ensure machining accuracy.

Machining and monitoring: Start the CNC lathe, perform automated machining according to the program, and monitor the machining process in real time to ensure machining quality.

Inspection and delivery: Use measuring tools to inspect the processed parts to ensure that they meet the design requirements, and then package and deliver the completed parts.

CNC lathe machining is an efficient and precise manufacturing method widely used in various industries. By choosing hi-precision’s CNC lathe machining services, you will receive high-quality, high-precision, cost-effective, and customized machining services. Our advanced equipment, professional team, and high-quality customer service will ensure the success of your project and meet all your needs.

Parts Machined by CNC Lathe