CNC machine is computer-controlled automated machine used to precisely process a variety of materials, such as metals, plastics, and composites. CNC machine is widely used in the manufacturing industry and can achieve high-precision, high-efficiency, and high-consistency processing.

Quickly Understand CNC Machine

The Basic Principles of CNC machine

CNC machine is a computer control system (CNC controller) to interpret pre-written programs (usually G-code) and control the movement and operation of the machine tool. The program contains processing parameters such as tool path, feed rate, cutting depth, etc.

The main components of CNC machine

CNC controller: responsible for interpreting G code and controlling the movement of the machine tool.

Machine tool body: including mechanical parts such as bed, spindle, worktable, tool, etc.

Drive system: including servo motor and stepper motor, used to drive each motion axis.

Feedback system: such as grating scale and encoder, used to monitor and feedback the actual position and speed of the machine tool.

Operation panel: used to input and display processing parameters and manually control the machine tool.

Types of CNC Machine

CNC milling machines: used for milling, drilling, tapping and contouring.

CNC lathes: used for turning cylindrical parts such as shafts and pipes.

CNC grinders: used for high-precision grinding.

CNC electrical discharge machining (EDM): uses electrical discharge to remove material from conductive workpieces.

CNC laser cutting machines: use laser beams to cut materials.

Advantages of CNC machine

High precision: It can achieve extremely high processing accuracy and is suitable for manufacturing complex and precise parts.

High efficiency: It has a high degree of automation, reduces manual intervention, and improves production efficiency.

High consistency: It can mass-produce parts with high consistency.

Flexibility: It can quickly change the processing program to adapt to different processing requirements.

Safety: It reduces manual operation and reduces operational risks.

Application of CNC machine

CNC machine tools are widely used in aerospace, automobile manufacturing, mold manufacturing, medical equipment, electronic products and other fields. It can process a variety of materials, including metals, plastics, composite materials, etc.

Basic operating steps of CNC machine

Design: Use CAD software to create 3D models of parts.

Programming: Use CAM software to generate G-code.

Settings: Install tools and workpieces, set zero points and machining parameters.

Processing: Start the CNC machine and process according to the program.

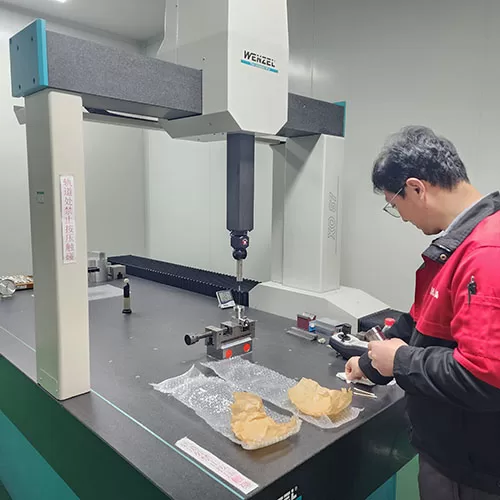

Inspection: Use measuring tools to inspect the processed parts to ensure compliance with design requirements.

Precautions for CNC machine

Tool selection: Choose the right tool according to the material and processing requirements.

Cutting parameters: Reasonably set the cutting speed, feed speed and cutting depth.

Coolant: Using coolant can reduce tool wear and improve processing quality.

Safe operation: Follow safe operating procedures, wear protective equipment, and avoid accidental injuries.

The price of CNC machine

The price of CNC machines varies depending on factors such as their type, size, complexity, brand, and features. Here are the price ranges for some common CNC machines:

Entry-level desktop CNC routers: cost between $150 and $500 and are suitable for beginners and hobbyists.

Hobby CNC router machines: cost between $1,000 and $3,000 and offer enhanced features and performance.

Small CNC lathes: cost less than $5,000 and are suitable for small workshops and hobbyists.

Entry-level 2-axis lathes: cost between $15,000 and $50,000 and are suitable for small and medium-sized businesses.

Professional CNC machines: cost between $50,000 and $100,000 and are suitable for high-volume manufacturing operations.

Entry-level 3-axis milling machines (VMCs): cost between $50,000 and $100,000 and are suitable for a range of machining tasks.

Production CNC Lathes: Cost between $50,000 and $300,000 and are suitable for large-scale production environments.

Production 3-axis CNC Mills: Cost between $100,000 and $500,000 and are suitable for demanding machining tasks.

Production 5-axis CNC Mills: Cost over $500,000 and are suitable for machining complex parts.

How to choose CNC machine

Selecting a CNC machine is a complex process that requires a combination of factors to ensure that the equipment you choose meets your production needs and budget. Here are some key steps and considerations to help you choose the right CNC machine:

- Understand your processing needs

Material type: Determine the type of material you will be processing, such as metal, plastic, composite, etc.

Part size and complexity: Evaluate the size, shape, and complexity of the parts to be processed.

Production volume: Consider the required production volume, whether it is small batch production or large batch production. - Choose the right type of machine tool

CNC milling machine: Suitable for milling, drilling, tapping, and contouring.

CNC lathe: Suitable for turning cylindrical parts such as shafts and pipes.

CNC grinder: Used for high-precision grinding.

CNC electrical discharge machining (EDM): Used for processing conductive materials.

CNC laser cutting machine: Used to cut a variety of materials. - Consider the technical parameters of the machine tool

Number of axes: Multi-axis machines (such as 3-axis, 4-axis, 5-axis) can process more complex parts.

Spindle speed: affects cutting speed and surface quality.

Feed rate: affects machining efficiency.

Table size: ensure that the table can accommodate the parts you need to machine.

Tool capacity: the capacity and type of automatic tool changer. - Evaluate brands and manufacturers

Brand reputation: choose a well-known brand with a good record of quality and reliability.

Customer support: find out about the after-sales service and technical support provided by the manufacturer or dealer.

User reviews: check the reviews and feedback of other users. - Budget and cost

Initial purchase cost: includes the price of the machine tool itself.

Operating costs: include power consumption, coolant, tools and maintenance costs.

Long-term return on investment: consider the productivity and life of the machine tool. - Software compatibility

Control system: ensure that the CNC machine’s control system is compatible with your CAD/CAM software.

Software features: evaluate the ease of use and functionality of the software interface. - Shop environment and infrastructure

Space requirements: ensure that the shop has enough space to accommodate the machine tool.

Power and ventilation: ensure that there is adequate power supply and good ventilation conditions.

Material handling: consider how materials are stored and handled. - Maintenance and training

Maintenance plan: Understand the maintenance services and spare parts supply provided by the manufacturer.

Operation training: Ensure that operators and programmers are fully trained to operate the machine safely and efficiently. - Site inspection and test machine

Site inspection: Visit the manufacturer or dealer’s showroom to see the machine in person.

Test machine: If possible, conduct a test machine operation to evaluate the performance and ease of operation of the machine. - Refer to the above CNC machine price information

Selecting a CNC machine requires a comprehensive consideration of processing requirements, technical parameters, brand reputation, budget, software compatibility, workshop environment, maintenance and training, etc. By carefully evaluating these aspects, you can choose the CNC machine that best suits your needs.

Visit Hi-Precision’s CNC Machine and Workshop