We provide CNC milling PCB service to global buyers. PCB is the abbreviation of the printed circuit board. PCB is a key component in the electronic components industry. CNC milling is a process used to manufacture precision parts. It is a process in which an entire metal block is cut into a target part through a subtractive motion on a CNC milling machine. CNC milling is currently the main method for producing PCBs in the electronic components industry.

METHOD OF CNC MILLING PCB

The technology of circuit board CNC milling includes selecting the feed position, compensation method, positioning method, frame structure, and CNC tool point, which are all important aspects to ensure the accuracy of milling. The following are the precision control methods of PCB board milling. Feed direction and compensation method: When milling the external contour of the printed circuit board, feed in the opposite direction. This is commonly referred to as up-milling. When milling frames or slots inside PCB circuit boards, the surface milling method is used. Positioning methods can be divided into two types; one is internal positioning, and the other is external positioning. Positioning is also very important for process designers. Generally, the positioning plan should be determined during the early production of PCB circuit boards. Internal precise positioning is a commonly used method. To put it bluntly, internal positioning is to select mounting holes, plug holes, or other non-metallic holes in the printed circuit board as positioning holes. The relative position of the holes strives to be on opposite corners and try to choose large-sized holes. Plated through holes cannot be used. Under the premise of ensuring the precise positioning of the printed circuit board, the fewer the total number of nuts, the better.

THE BASE MATERIAL OF PCB

- Aluminum

- Copper

- Phenolic Resin

- Fiberglass (FR4)

- Polyimide

CNC milling PCB, by adjusting the processing parameters of the CNC milling machine, such as cutting speed, rotation speed, cutting depth and cutting angle, these four materials are processed into PCB base plates.

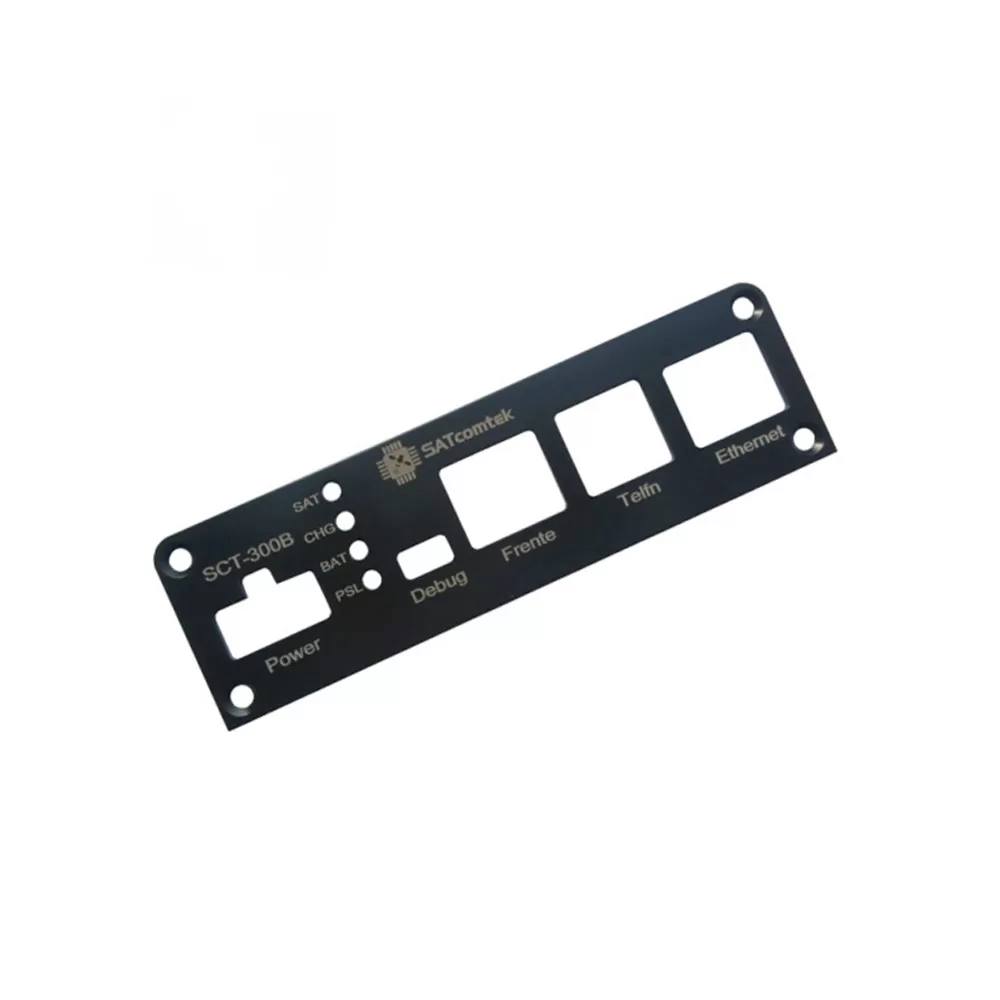

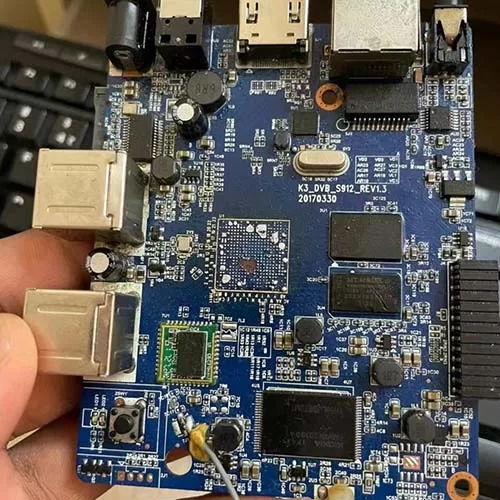

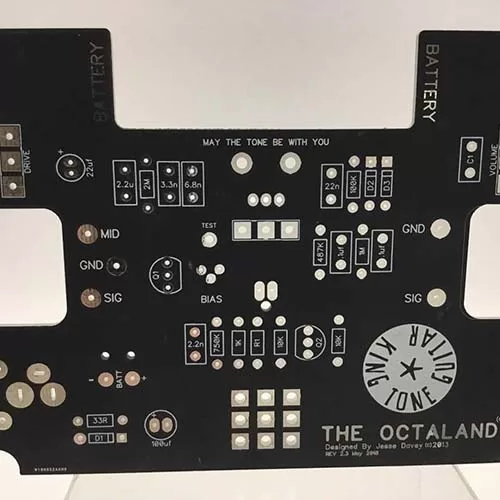

PCB WE MADE