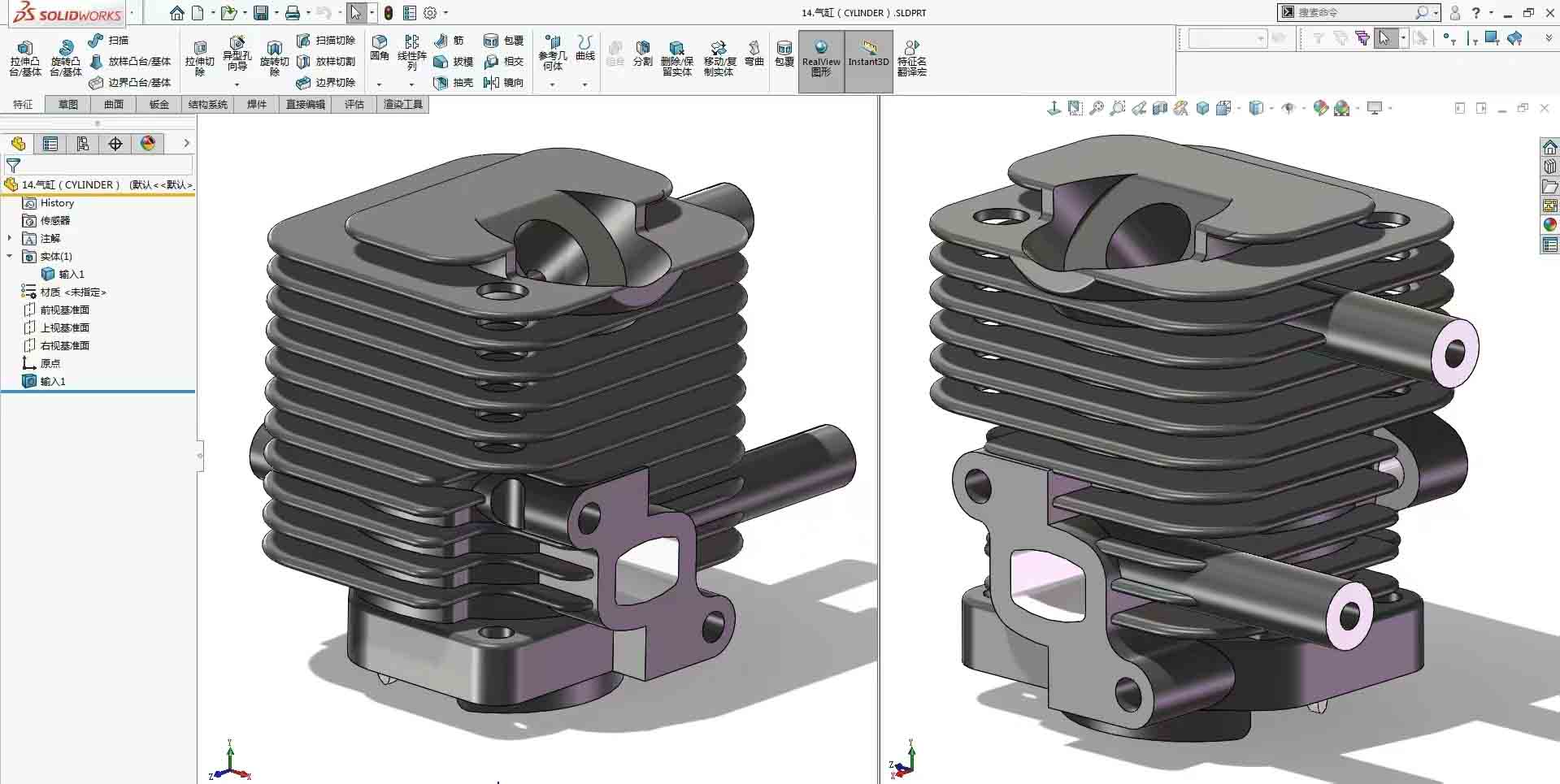

5 axis CNC machining engine block refers to an engine block processed using a 5-axis CNC machine tool. The engine block is one of the main components of the engine and is responsible for supporting and securing various engine components such as cylinders, crankshafts, and pistons. By using a 5-axis CNC machine tool, the engine block can be machined and engraved with high precision.

What is 5 Axis CNC Machining?

5-axis CNC machine tools have higher processing flexibility and precision than traditional 3-axis or 4-axis machine tools. It can move simultaneously on three linear axes of X, Y, and Z and two rotary axes (usually A and C axes), making it possible to cut at multiple angles and directions. This multi-axis motion can achieve more complex shapes and geometric structures, improving machining accuracy and efficiency.

In the processing of engine blocks, more complex geometries such as inclined holes, bevels and curves can be achieved using 5-axis CNC machines. This high-precision machining provides better sealing, heat dissipation and performance optimization, thereby improving overall engine performance and reliability.

It should be noted that five-axis CNC machining of engine blocks requires professional technology and equipment and is usually used for high-end and complex applications. So do you know how 5-axis CNC machine tools achieve precise processing when manufacturing engine blocks?

Cast Iron Engine Block

The cylinder block material of the B12\B12 MCE\B15 four-cylinder inline engines produced by a certain automobile factory is HT250 cast iron, sharing the positioning surface and positioning pin hole. The key points of its processing are:

- Roughing unit: rough milling of surfaces, rough boring of cylinder holes, processing of semi-finishing and finishing positioning surfaces and positioning pin holes, rough and fine milling of thrust surfaces.

- Semi-finishing unit: drilling and tapping threaded holes on each surface, drilling and reaming positioning pin holes on the combustion chamber surface, and fine milling the bearing cap joint surface.

- Finishing unit: drilling and tapping threaded holes on the front and rear end faces, drilling and reaming positioning pin holes on the front and rear end faces, fine boring of crankshaft holes and cylinder holes, and fine milling of the top surface.

In the process of 5 axis cnc machining engine block, our factory uses MAG S211 or S321 five-axis CNC horizontal machining center, which is characterized by: screw repeatability 0.005mm; B-axis repeatability 0.003mm; spindle runout proximal end 0.003 mm, distal end 0.015mm. Cutting tools from Ingersoll, Walter, Guhring and Mapal are used in machining.

The specific process plan of this product: rough machining → semi-finishing → intermediate cleaning → intermediate leak test → tighten the main bearing cap → finishing → honing the cylinder bore and crankshaft bore → final cleaning → final leak test (manually tighten the oil plug, automatically press fit stuffy cover) → offline. At the same time, the following measures are taken: quality assurance and traceability, regular measurement of CMM and inspection tools, Q-das data analysis, marking and reading of upper and lower lines, A/B line identification, and tightening and leak test qualification marks.

Electronic Control Engine Cylinder Block

In the process of 5 axis cnc machining engine block, boring, milling and drilling are used. Slightly different from the mechanical engine, in terms of machining, the top surface roughness of the electronically controlled engine block is changed from Ra3.2 µm to Rz15 µm; the crankshaft hole & camshaft hole are honed after fine boring to improve The roundness, straightness and surface roughness of the crankshaft hole & camshaft hole are improved.

An engine manufacturer uses the German CROSS HULLER automatic production line to process the cylinder block of an electronically controlled engine. The main processing contents include: front and rear end face positioning ring holes, semi-precision boring/precision boring crankshaft holes & camshaft holes, precision turning water pump holes & oil pump holes, Precision milling of front and rear end surfaces, top plane, crankshaft hole & camshaft hole online measurement, etc.

The adopted tool solution is as follows:

- Boring bars for semi-finish boring/finish boring of crankshaft holes & camshaft holes and boring heads for finishing water pump holes & oil pump holes are all designed and produced by Mapal. Among them, the camshaft hole boring bar itself adopts an intermediate sliding bearing structure, which can effectively reduce the friction between the boring bar and the intermediate support sleeve during use, which is very beneficial to improving the roundness and taper of the camshaft hole.

- The front and rear end faces and top plane of precision milling adopt ISCAR’s 5NKL series cap-type cutterhead, which has the characteristics of light weight and sharp cutting. The blade adopts HNCF model, which can achieve 12 indexing times and has low cost of use.

- The hole processing tools use Walter’s coated reamers and reamers, which have very good wear resistance and stable hole diameter.

Since the engine block was put into production, its production line has been operating well, and the product’s processing dimensional stability and surface quality are very good. The tool life is also long, the life of the front and rear end mills can reach about 1200 pieces/edge, the life of the top plane milling cutter can reach about 400 pieces/edge, the life of semi-precision boring/precision boring crankshaft hole & camshaft hole can reach 1200 pieces /blade.

Six-Cylinder Diesel Engine Block

The BF1013/2012 four- and six-cylinder diesel engines adopt a single fuel injection pump structure, and the oil pump tappet hole has a keyway hole for installation. The BF1013 series adopts a wet cylinder liner structure, while the BF2012 series adopts a dry cylinder liner structure. The key points of its processing are:

- The dimensional accuracy of the spindle hole is H6, the surface roughness is Rz20µm, the cylindricity is 0.01mm, the runout of each hole to the adjacent hole is 0.02mm, and the runout to holes 1 and 7 is 0.04mm.

- The cylinder bore size accuracy is H7, the surface roughness is Rz16µm, the cylindricity is 0.01mm, the stop depth tolerance is 0.03mm, and the adjacent stop position tolerance is 0.015 mm.

In the process of 5 axis cnc machining engine block is: basic processing – rough milling and semi-finish milling of the top and bottom surfaces of the cylinder block, rough machining of the semicircular hole of the cylinder bore spindle and oil pump hole, milling of the tiles, block gun drilling of the oil passage – cleaning – leak test – oil hole Processing of threaded holes, rough boring of tappet holes and camshaft holes, fine milling of main bearing cap mounting surfaces – cleaning – installation of main bearing caps – three-axis hole processing – milling of top surfaces, boring of cylinder holes, oil pump holes and tappet holes – removal Burr—high-pressure cleaning—installation of accessories—leak test—finished product inspection off the line.

In actual production, an automatic production line composed of 5-axis CNC machine tools is used to finish the cylinder hole, oil pump hole and tappet hole on the top surface of the cylinder block; Sandvik Coromant CBN tools are used for surface milling; MAPAL is used for precision boring. The single-edged boring tool has a carbide-coated blade; the precision boring of the cylinder hole adopts automatic measurement and automatic compensation technology; the precision boring of the single pump hole and tappet hole adopts automatic measurement.

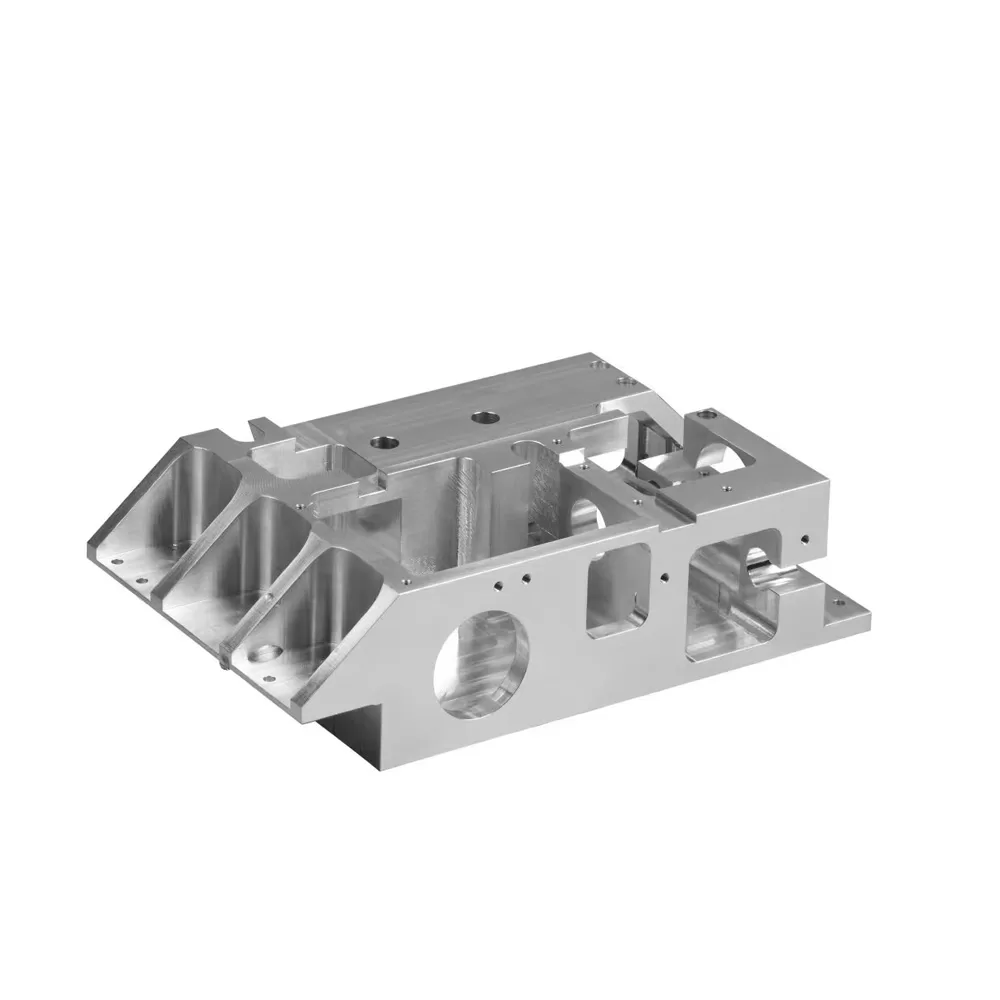

Get a 5 Axis Cnc Machining Engine Block Quote Now!

Xi’an Hi-Precision Machinery Co., Ltd is a CNC machining company certified by the Chinese government. Our main processing equipment includes: CNC lathes, CNC milling machines, five-axis CNC machining centers, etc. We provide precision machining services to various industries around the world, processing according to drawings. If you need 5-axis CNC machining engine block service, please contact us for a quote!