Hi-Precision provides rapid prototyping service to buyers in various industries around the world! Hi-Precision is a professional CNC machining company! We use CNC machining methods to quickly create prototypes for you. Contact us for a free and fast prototyping solution.

WHAT IS PROTOTYPE

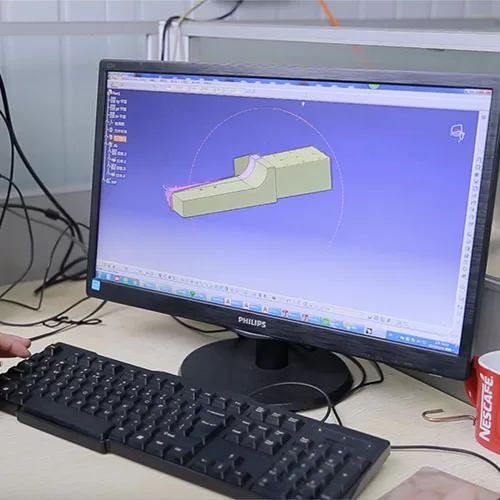

With the application of computer-aided design, product modeling and design capabilities have been greatly improved. However, after the product design is completed and before mass production, samples must be produced to express the design concept, quickly obtain feedback information on the product design, and evaluate the product design and feasibility. The sample produced during this process is also called a prototype.

We use CNC technology for rapid prototyping. CNC machining is a machining method that uses digital information to control the displacement of parts and tools. Using a CNC machine to process parts with complex shapes does not require complex tooling. If you want to change the shape and size of parts, you only need to modify the part processing program, which is suitable for new product development and modification.

ADVANTAGES OF PROTOTYPING

- Realize a physical model in a short time.

- It shows the physical shape, specifications and functionality of your part.

- Before mass production, test the functionality of the parts to identify design flaws, etc.

- Optimize CNC machining process.

- Create different versions of parts without extensive design modifications.