Xi’an Hi-Precision Machinery Co., Ltd provides precision turning services to various industries around the world! We are a foreign trade company specializing in customized processing parts. Click “Contact Us” below to get free manufacturability feedback. Once our technicians confirm your order and reach a consensus with you, you can get free samples within 7 days.

WHAT IS PRECISION CNC TURNING

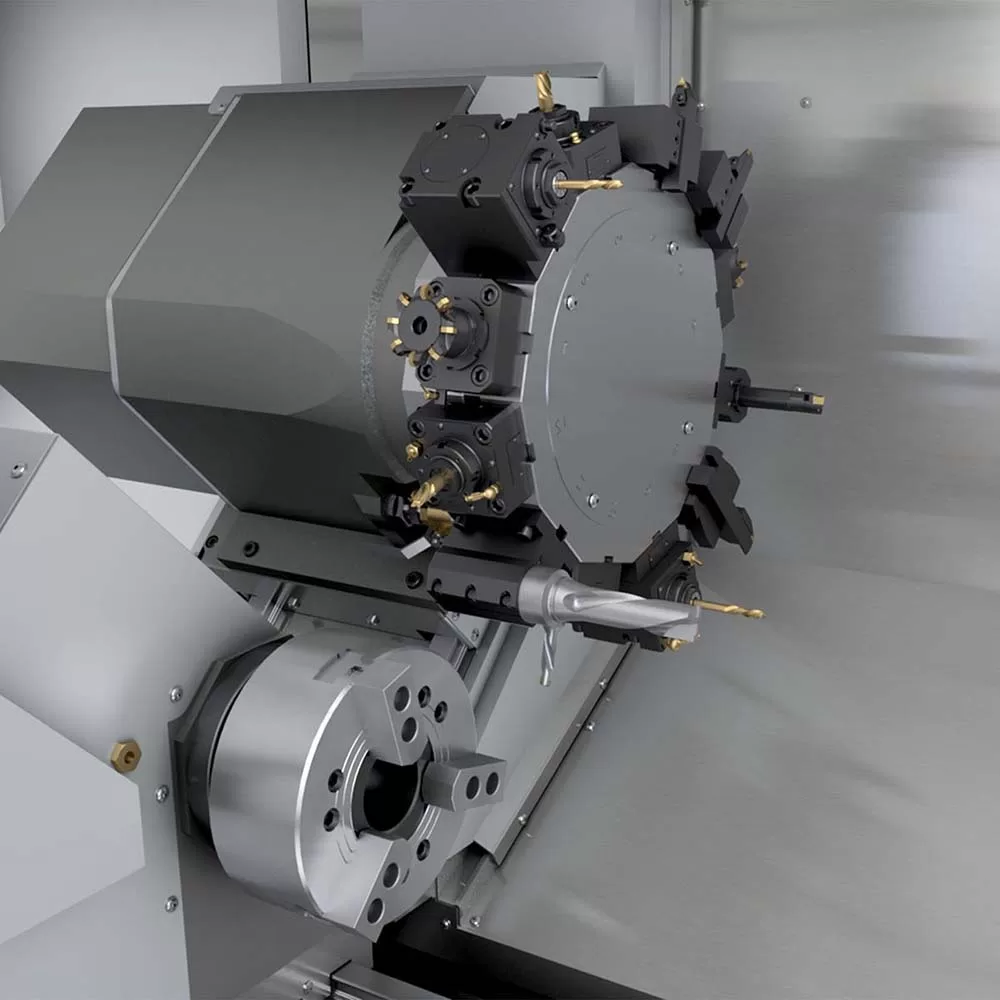

Precision CNC turning is the process of manufacturing high-precision parts using a computer numerical control (CNC) system on a CNC lathe. Key to this process is ensuring that the CNC turned parts produced have the dimensional accuracy required by the customer. Computer digital technology is used to precisely control the movement of the tool and the rotation of the workpiece to produce cylindrical or axially symmetric parts with small size and high precision requirements.

Precision CNC turning can be used not only to make metal parts, but also plastic parts. Below is a list of materials that can be used to make precision CNC turned parts:

- Metal: aluminum, steel, copper, brass, titanium…

- Plastic: PEEK, POM, ABS, PS, PP….

Generally speaking, materials that can be used for CNC lathe processing need to have a certain hardness and high temperature resistance. Good cutting performance is an important factor in ensuring product quality. Therefore, our technicians will conduct trial cutting and other operations before officially starting your project to avoid large-scale material waste.

If your project requires tight tolerances and ultra-high quality, then try our precision CNC turning manufacturing process for high-quality turned parts. Currently, our company mainly provides precision CNC turning parts for the following industries:

- Aerospace

- Medical

- Electronic

- Mechanical

- Communication

- Automobile

WHY CHOOSE OUR PRECISION TURNING SERVICES?

We use Swiss precision CNC lathes to manufacture precision turned parts to tight dimensional tolerances, ensuring the parts meet your expectations and function as they should. The precision CNC turning process is automatically completed by CNC lathes. This process requires almost no human intervention and has high production efficiency. This efficient and simple mechanized operation is ideal for mass production.

In addition to CNC turning, our factory also provides CNC milling, wire cutting, mold processing and other services. Whether it is large-volume production or small-volume manufacturing, we will be very happy to serve you. If you can accept the high manufacturing cost, the MOQ can also be 1 piece.

In addition, in addition to free sample delivery service, in order to ensure product quality, we conduct comprehensive quality inspections on all parts before each shipment, and also guarantee after-sales service.