Description

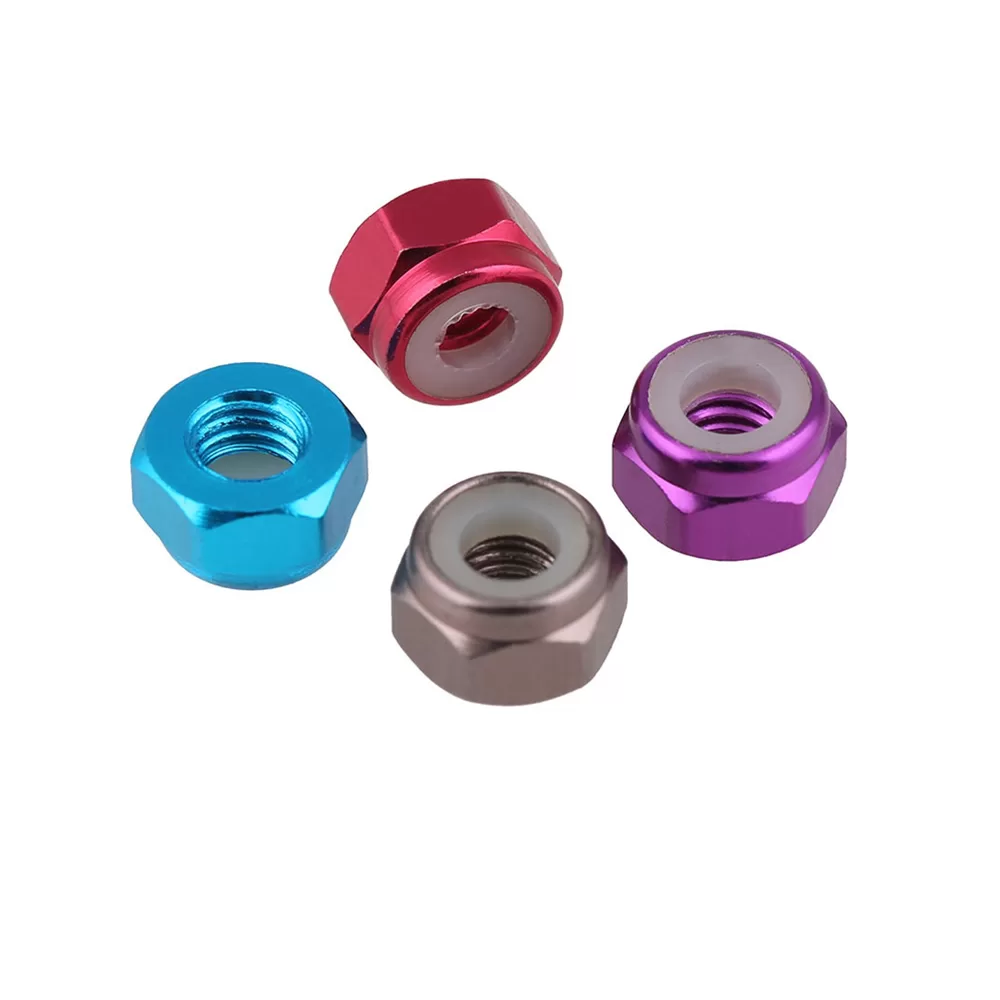

The “CNC Turning Products Wholesale Aluminum Nuts Anodized Gold” displayed on this product page is a pre-sale product. If you need CNC turning products, please click “Contact Us” on the product page and send your drawings to our email for manufacturability feedback. Once we confirm your order, you can receive free samples within 7 days.

Our company’s processing technology includes CNC machining, milling, tapping, drilling, slotting, broaching, thread rolling, grinding, lathe machining, and mold machining. CNC milling and turning is currently the most popular manufacturing process, which can process various simple or complex non-standard parts. Nonstandard parts refer to parts that require customized processing and are generally not available in stock. Our company has rich manufacturing experience in the field of customized processing and can provide you with the most budget-saving CNC machining solution for your project. We strive to meet the needs of every customer, therefore we support transaction models such as small batch, large batch, and on-demand manufacturing, aiming to establish long-term cooperative relationships with every customer.

The materials we can use are divided into two categories: metal and plastic. Metals: stainless steel, aluminum, copper, brass, titanium, etc; Plastics: acrylic, PEEK, nylon, rubber, etc. In addition, it also includes composite materials such as carbon fiber.

Our factory currently has processing equipment such as CNC lathes, CNC milling machines, wire-cutting machines, etc. Welcome to visit our CNC machining workshop at any time.

We have obtained the ISO9001:2015 quality certification and strictly follow the quality inspection procedures. Our quality inspection equipment includes calipers, micrometers, height gauges, angle gauges, thread gauges, laser interferometers, coordinate measuring machines, image measuring instruments, surface roughness meters, profilometers, hardness testers, optical microscopes, etc. In the CNC machining process, selecting appropriate testing equipment as needed can effectively improve machining quality and efficiency.

Contact us to obtain CNC turning products quotes, delivery times, and manufacturability feedback.