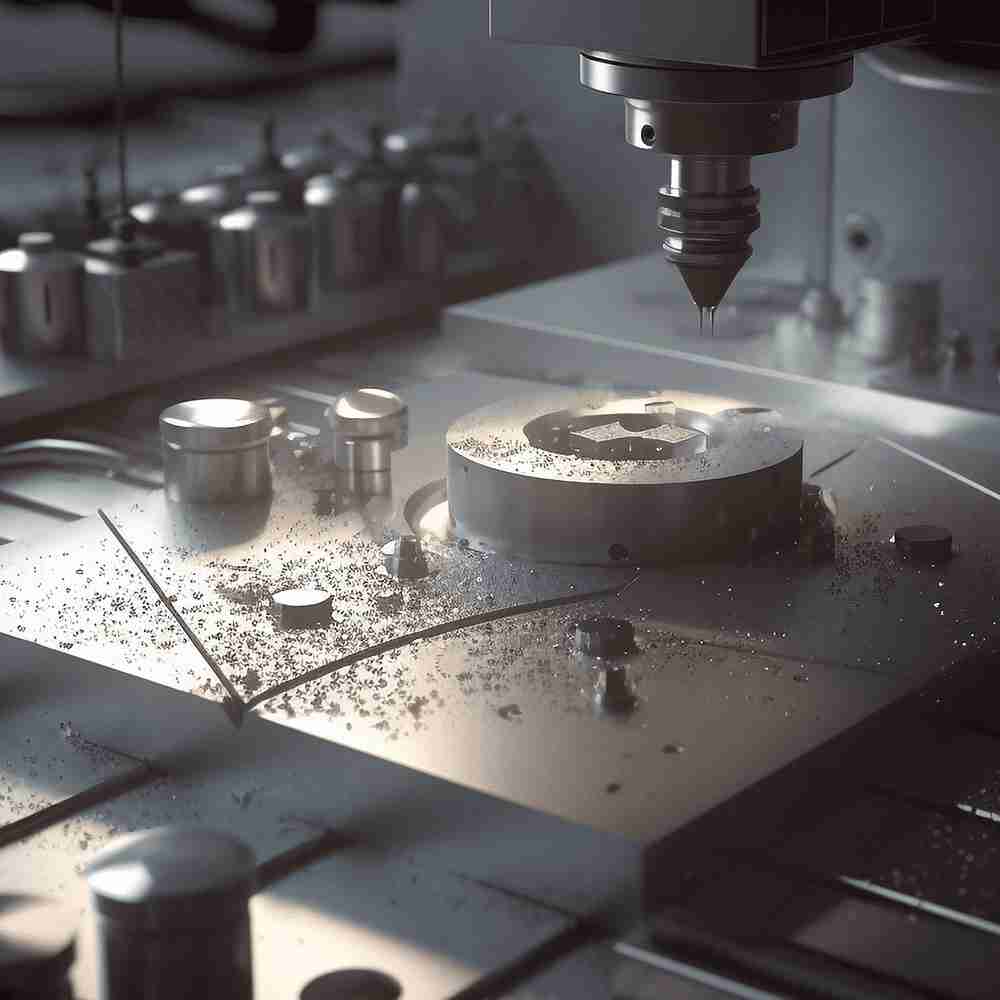

XI’AN HI-PRECISION MACHINERY CO., LTD provides the highest quality small batch CNC machining customization services. We can help various industries around the world produce non-standard parts with complex geometric shapes and excellent surface smoothness on demand.

THE MEANING OF SMALL BATCH CNC MACHINING

Small batch CNC machining refers to the use of CNC lathes or CNC milling machines by CNC machining companies to manufacture small quantities of parts required by customers in a single operation. With the increasing demand for more customized products and shorter delivery times in the market, this processing model has become a popular trading method and is widely used in industries such as healthcare, aerospace, automotive, construction, electronics, and consumer goods. Small batch CNC machining usually includes two levels of meaning:

- The first type: Small batch production of individual components. The use of CNC turning and milling technology to manufacture a certain part in small quantities according to customer needs is also known as small batch CNC machining. Correspondingly, there is also large-scale CNC machining;

- The second type: Small batch production of various different parts. Sometimes, the parts that customers need to manufacture are not single, often multiple components that need to be assembled, but the quantity requirement for each type of part is not high, which may be 10 or 50. This production mode also belongs to small batch CNC machining.

The above two small batch processing modes are currently the mainstream production methods for customized non-standard parts, because single batch small quantity customization can not only avoid unnecessary material waste, but also ensure product quality.

MATERIALS THAT CAN BE USED FOR SMALL BATCH CNC MACHINING OF CUSTOMIZED PARTS

Many different types of materials are compatible with small batch CNC customization processing. Some of them are listed below:

- aluminum: 7075, 6061;

- stainless steel: 304, 316;

- brass;

- copper;

- PEEK;

- ABS;

- Acrylic

The process that can be used for small batch CNC machining of customized parts:

CNC turning

CNC turning generally refers to the process of machining parts on a CNC lathe. CNC turning is the most basic and common cutting method. Most workpieces with rotating surfaces can be machined using small batch CNC turning methods, such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, grooves, threads, and rotary forming surfaces.

CNC milling

CNC milling generally refers to the process of machining parts on a CNC milling machine. Small batch CNC milling can process parts with particularly complex contour shapes or difficult to control dimensions, such as mold parts, shell parts, etc. It can also process parts that cannot be processed or are difficult to process.

CNC drilling

Small batch CNC drilling is mainly used for drilling, reaming, chamfering and other processing. Mainly used in the automotive, mold, shipbuilding, aerospace, and engineering machinery industries, especially suitable for hardware parts with multiple holes that need to be machined.

Manufacturing a customized part using CNC usually requires multiple processes of composite processing, usually turning first and then milling. The specific operation steps also need to be adjusted according to the drawings of the parts. CNC is very suitable for small batch custom machining parts. If you are planning to find a suitable supplier for your project, please contact us immediately:

Whatsapp: +86 18991129810

VIEW THE SMALL BATCH MACHINED PARTS WE MADE FOR SAVANNAH CUSTOMER