We use wire cutting machines to provide high-quality metal wire cutting services to customers around the world. Contact us to get wire edm cutting service.

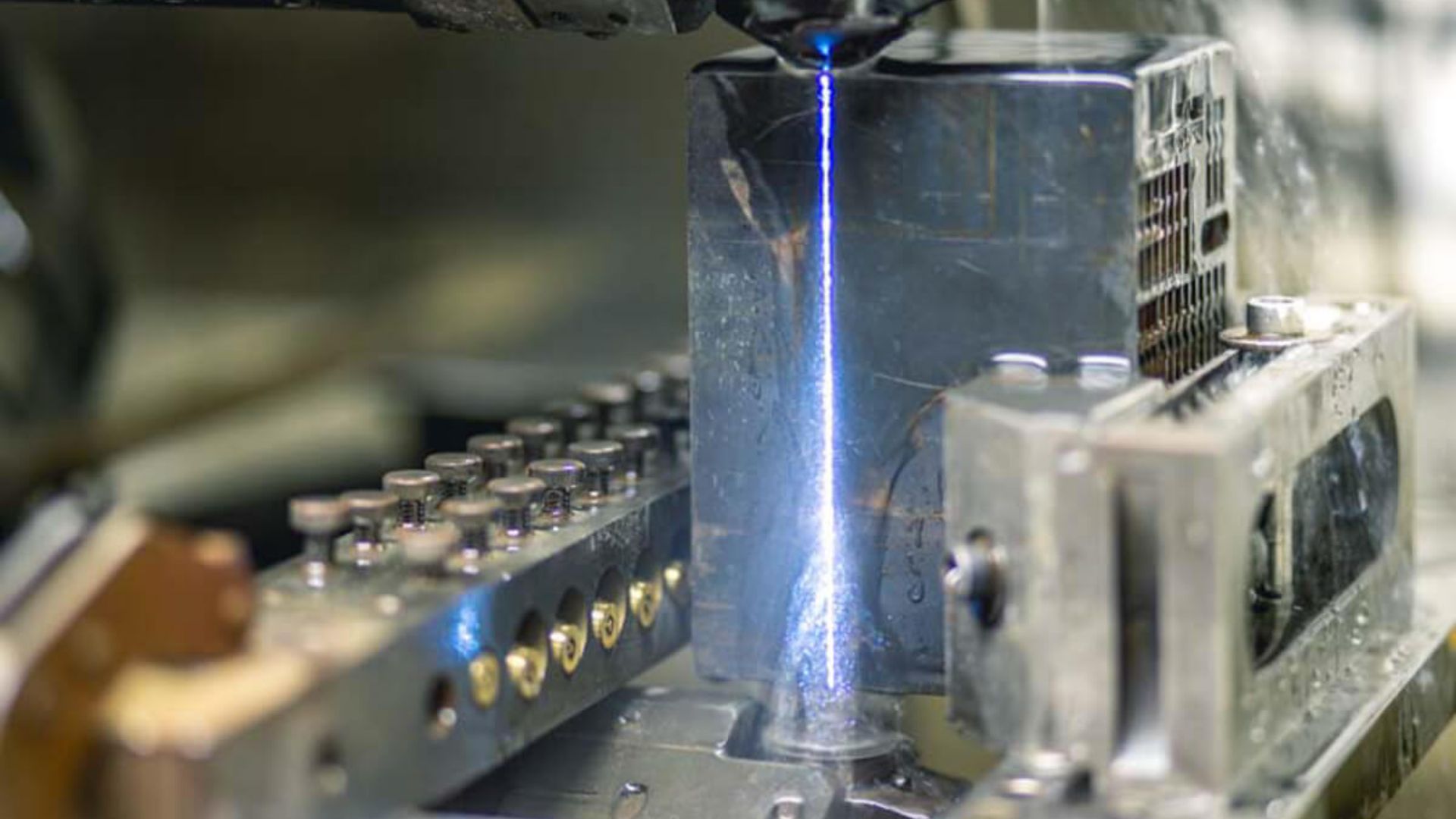

Wire-cut electrical discharge machining is a metal manufacturing process that obtains the desired shape by using electrically charged wires to remove tiny particles and shape the part. Wire-cut machining is generally used for processing block materials (such as molds and gears, precision fixtures) and post-processing of hardened parts that require high machining accuracy.

Materials Available for Wire Cutting

Wire EDM (Electrical Discharge Machining) is a type of CNC machine that uses an electrically charged wire to remove microscopic particles and shape the part. The wire is continuously fed under tension on a vertical axis, and discharge voltage is applied through the wire, crosses via a dielectric liquid, and strikes the grounded workpiece. The workpiece is moved in an X-Y plane to trace a cut pattern through the material. The following are the avaliable materials for wire cut:

- Steel: Wire EDM can cut through various types of steel, including pre-hardened die steels and high alloy steel.

- Titanium: Wire EDM can cut through titanium, which is a strong and lightweight metal commonly used in aerospace and medical applications.

- Aluminum: Wire EDM can cut through aluminum, which is a lightweight and corrosion-resistant metal commonly used in the automotive and aerospace industries.

- Brass: Brass is a copper and zinc alloy that is commonly used in wire EDM. It is highly conductive and can be cut more quickly the more zinc there is in the alloy.

- Copper: Copper is another highly conductive material that can be cut using wire EDM. However, it is generally not cost-effective to cut soft materials such as copper, bronze, brass, and non-hardened steel, all of which can be easily machined by cheaper conventional means.

- Tungsten and Molybdenum: Wire EDM can cut through tungsten and molybdenum, which are hard and brittle metals commonly used in the aerospace and defense industries.

In summary, wire cutting or wire EDM is a process that uses an electrically charged wire to cut through conductive materials. It can cut through various materials, including steel, titanium, aluminum, brass, copper, tungsten, and molybdenum. However, it is generally not cost-effective to cut soft materials such as copper, bronze, brass, and non-hardened steel, all of which can be easily machined by cheaper conventional means.

What Are the Applications of Wire Edm Cutting Service?

Wire cutting has several applications in various industries, including:

- Mold and die manufacturing: Wire cutting is commonly used in mold and die manufacturing processes, particularly for extrusion dies and blanking punches. It can be used to create complex shapes and designs with high precision and repeatability.

- Aerospace and defense: Wire cutting is used in the aerospace and defense industries to create parts for engines, fuel systems, landing gear, and other high-stress, high-temperature systems. The parts produced using wire cutting can survive the extreme heat and pressure required to keep the technology running.

- Automotive: The automotive industry prefers wire cutting over conventional techniques because it ensures precise molding and drilling of even larger parts. The materials produced using wire cutting are more enduring and durable due to the EDM process.

- Metal fabrication: Wire cutting is used in metal fabrication to create high-precision parts from conductive materials such as steel, titanium, aluminum, brass, tungsten, and molybdenum. It is particularly useful for cutting pre-hardened materials.

In summary, wire cutting or wire EDM is a process that uses an electrically charged wire to cut through conductive materials. It has several applications in various industries, including mold and die manufacturing, aerospace and defense, automotive, and metal fabrication. Wire cutting is particularly useful for creating complex shapes and designs with high precision and repeatability.

Other Parts Machining Services We Provide You:

- CNC turning services

- CNC milling services

- CNC machining prototype service

- Laser engraving services

Our company is a professional precision metal parts manufacturer, providing CNC machining parts services for various industries, these services include: prototyping, turning, milling, drilling, cutting, grinding, heat treatment, finishing, etc.