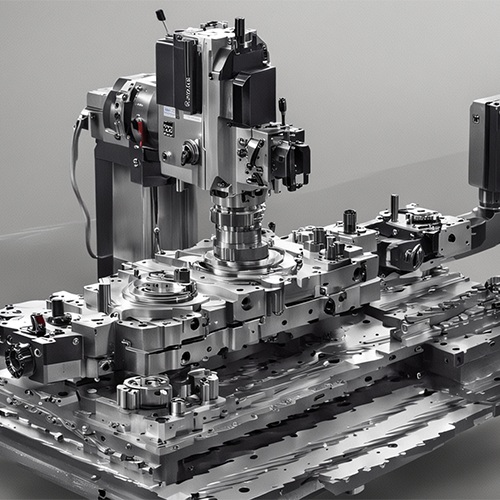

CNC milling and lathe combination machining is a processing method that integrates milling and turning functions, which allows complex mechanical parts processing to be completed through CNC programming in a single setting. Compared with using a milling machine or a lathe alone, this processing method can improve production efficiency, reduce the number of workpiece transfers, reduce labor costs, and improve processing accuracy.

Features of CNC Mill Lathe Combo Machining

- Multi-axis machining capability: CNC milling machines often have multi-axis machining capabilities, which means they can machine parts in multiple directions simultaneously.

- Mill-turning: Some advanced CNC machines are capable of performing turning and milling operations simultaneously, and such machines are called mill-turning machines.

- Automation: CNC machines are often equipped with automation features, such as automatic tool changing systems, which can reduce tool changing time and improve production efficiency.

- Programming: CNC machines require programming to control their operation. This usually involves using specialized software to create machining paths and set parameters.

- Accuracy: CNC milling and lathes can provide very high machining accuracy, which is essential for manufacturing precision parts.

- Complex shapes: Due to the flexibility of CNC machines, they can machine very complex and irregular shapes.

- Material adaptability: CNC milling and lathes can process a variety of materials, including but not limited to metals, plastics, and wood.

- Maintenance and calibration: In order to maintain machining accuracy, CNC machines require regular maintenance and calibration.

- Cost-effectiveness: Although the initial investment in CNC equipment may be higher, they can reduce long-term costs by reducing production time and improving efficiency.

- Safety: Operating CNC equipment requires compliance with strict safety regulations to ensure the safety of operators and equipment.

As technology develops, CNC milling and turning centers are becoming more and more popular. These machines are able to complete multiple machining operations such as turning, milling, drilling, and boring in one clamping, which is equivalent to a small production line. The development of CNC milling and turning centers has helped improve the processing capabilities of precision parts, especially in industries such as aerospace, automotive manufacturing, and medical devices.

CNC milling and lathe combination processing is an efficient and flexible processing method that is suitable for the precision processing needs of complex parts in modern manufacturing. As technology advances, this processing method will continue to be optimized to meet a wider range of industrial applications.