What is Medical CNC Machining?

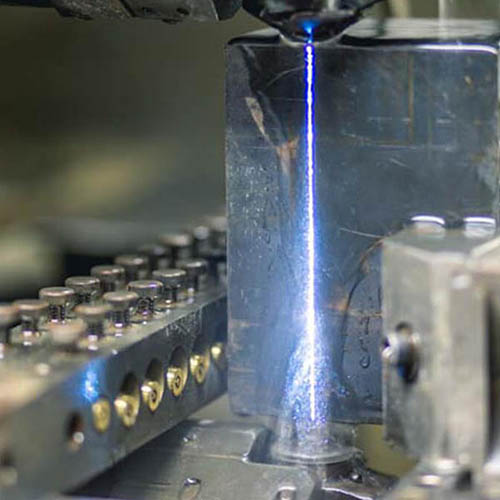

Medical CNC machining is the process of producing high-precision medical parts, equipment, and instruments using computer numerical control (CNC) machines.

The process is cost-effective and efficient, requiring no special tools and reducing the risk of errors. CNC machining is ideal for producing highly specialized medical devices, equipment, surgical products, prosthetics, and other products that often require one-off or one-off custom parts. Some common medical products machined using CNC include surgical instruments, spinal fixation components, bone fixation components, medical pump components, CT and MRI scanners, and implantable devices. CNC machining is used in the medical industry because it can produce parts faster and more efficiently than manual machining, and is fundamentally more precise and faster than manual machining. This also makes their machined products more precise. This becomes very important for machined products with tighter tolerances, such as prosthetics and medical machinery. CNC machining can also create molds for consistent and repeatable injections, which is important for making medical supplies like plastic face masks.

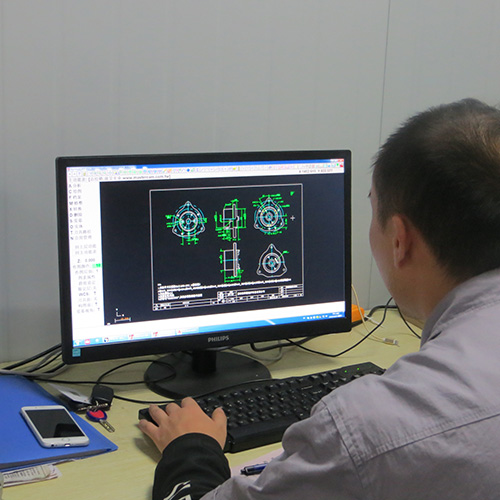

A key advantage of CNC machining is the ability to quickly and easily transfer digital programs between medical experts, product designers and manufacturing professionals. This capability greatly increases its efficiency in manufacturing high-quality and professionally CNC machined medical devices wherever they are needed. This advantage is especially valuable where time is of the essence. It allows for rapid creation and delivery of essential medical components.

In summary, medical CNC machining is the process of using computer numerical control machine tools to produce high-precision medical components, equipment, and instruments. It is cost-effective, efficient and ideal for producing highly specialized medical devices, equipment, surgical products, prosthetics and other products that often require one-off or one-off custom parts. CNC machining is used in the medical industry because it can produce parts faster and more efficiently than manual machining, and is fundamentally more precise and faster than manual machining.

the benefits of medical CNC machining

- The use of CNC machining technology to manufacture parts required by the medical industry is faster and more precise than traditional machining. And can meet the strict tolerance requirements and performance standards of medical parts.

- CNC machining requires no minimum order quantity and meets the needs of the medical industry for on-demand manufacturing.

- CNC machining enables easy transfer of digital programs between medical experts, product designers and manufacturing professionals. This capability greatly improves its efficiency in manufacturing high-quality and professional CNC-machined medical equipment.

- Medical CNC machining can quickly produce customized medical components. Depending on the complexity of the part, we can produce finished parts in a matter of hours or days.

- CNC machining makes it easy to achieve tight tolerances. Many complex medical devices also require very tight tolerances. Therefore, the biggest advantage of medical CNC machining is that it can produce parts with nearly 0 tolerances, which not only saves time and money, but also ensures that the medical components are suitable for their intended use.

Medical CNC machining services

The medical CNC machining services provided by our company can be customized and optimized according to customer needs. In addition, before shipment, we will conduct comprehensive testing of parts such as accuracy and hardness to ensure that the product quality is qualified before arranging shipment. Want to custom produce medical application accessories in small batches? Contact us today for a quote.

The titanium alloy prosthetic parts we process using CNC turning and milling technology:

Factors That Affect the Price of Medical CNC Machining:

- Type of machine: The cost of CNC machining depends on the type of machine used. 3-axis machines, including CNC milling machines, cost approximately $40 per hour to run, while CNC turning machines cost about $35 to run. Multi-axis machines are more expensive, ranging from $75-$120 per hour.

- Part design: The complexity of the part design can affect the cost of CNC machining. More complex designs require more time and effort to produce, which can increase the cost.

- Material cost: The cost of the material used to produce the part can also affect the cost of CNC machining. More expensive materials will increase the overall cost of the project.

- Finish: The desired finish of the part can also affect the cost of CNC machining. More complex finishes require more time and effort to produce, which can increase the cost.

- Labor costs: The cost of labor required to operate the CNC machine can also affect the overall cost of the project.

- Timeline: The timeline for the project can also affect the cost of CNC machining. Rush orders or tight deadlines may require additional resources, which can increase the cost.

- Shipping: The cost of shipping the finished product can also affect the overall cost of the project.

Why Precision Is Important in Medical CNC Machining?

- Accuracy: Medical components require high precision and accuracy to ensure they operate correctly and safely. Even small deviations in specifications can have harmful consequences for the healthcare industry. The precision and accuracy of medical CNC machining greatly reduces this risk and enables the production of high-quality parts.

- Tight Tolerances: Many complex medical devices require very tight tolerances, and CNC machining can easily achieve these service tolerances. This reduces the need for post-processing and minimizes the risk of errors. Not only does it save time and money, it also ensures that medical components are suitable for their intended use.

- Consistency: Medical CNC machining ensures that each part produced is identical to the previous one, which is critical to manufacturing safe and effective medical devices. This consistency is achieved through the use of computer programs that control CNC machines, ensuring that every part is produced to the same exacting standards.

- Repeatability: Medical CNC machining can produce medical parts quickly and accurately without the need for special tools, saving production time and tooling costs. This is especially important for low-volume production or custom parts, where precision and accuracy are still critical.

- Flexibility: CNC machining in the medical industry is also ideal for the production of surgical tools and instruments due to high precision requirements. This manufacturing technology provides a cost-effective way to produce complex and intricate parts that would be difficult or impossible to produce using other methods.

In summary, precision is important in medical CNC machining as it ensures accuracy, tight tolerances, consistency, reproducibility, and flexibility, all of which are critical to manufacturing safe and effective medical devices and components.