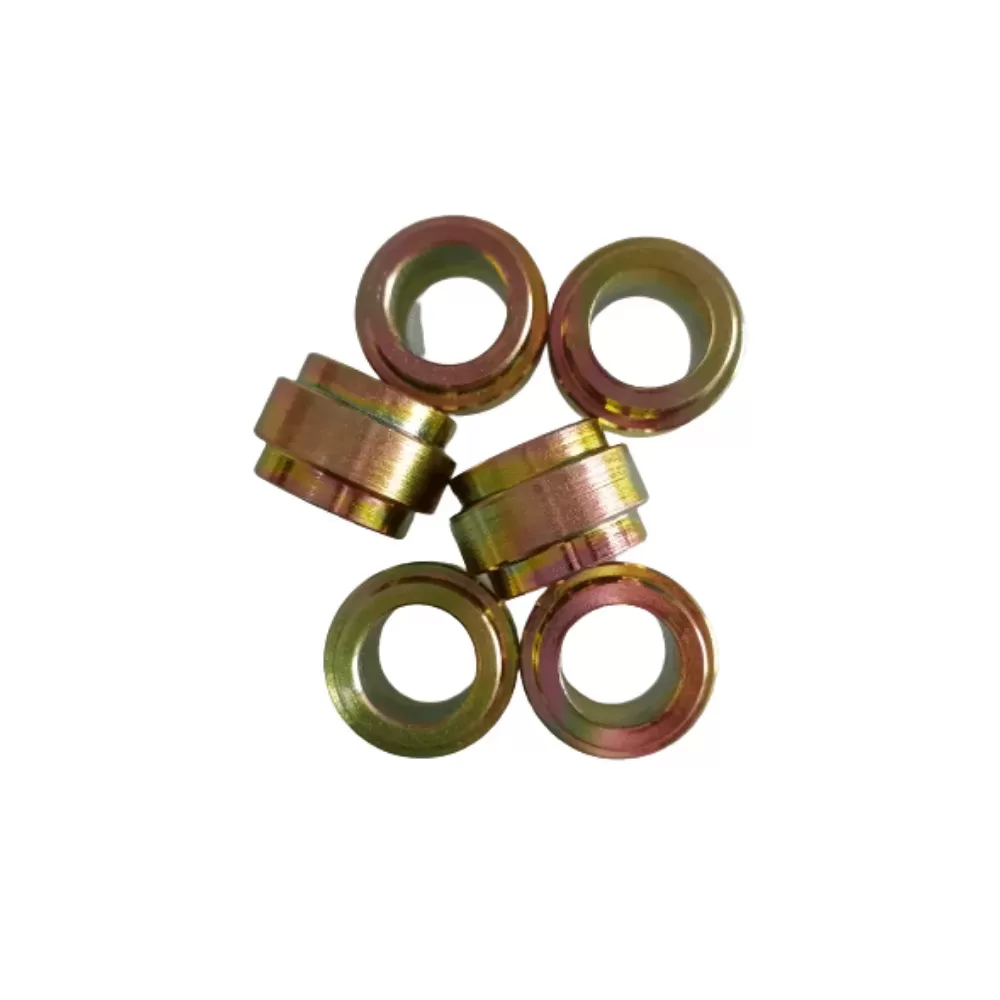

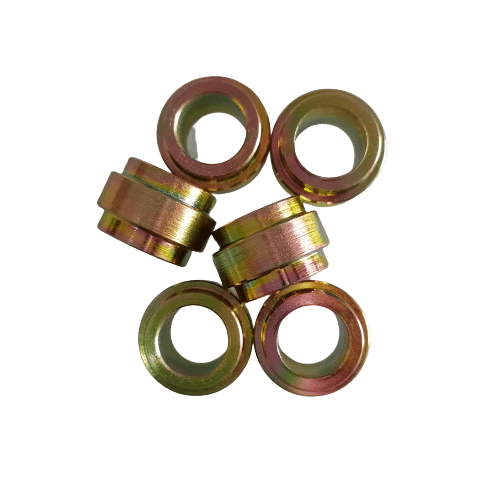

Description

The best China CNC turning machining parts manufacturer! CNC lathe custom metal galvanized rings! You can customize the appearance of your project based on CAD drawings, manufacture as needed, and the minimum order quantity can be 1 piece!