Xi’an Hi-Precision Machinery Co., Ltd. provides alloy CNC machining services for you. We focus on manufacturing precision non-standard metal alloy parts. With over 10 years of knowledge and experience, our team can produce the parts or prototypes you need in a timely manner. We can maintain strict tolerances in materials that are difficult to process, such as stainless steel, titanium, nickel alloys, etc. Our CNC alloy machining services use advanced multi axis CNC machining centers and various precision measurement equipment to ensure the highest quality products and customer satisfaction.

WHAT IS ALLOY?

Alloys are substances with metallic properties that are synthesized by two or more metals and metals or nonmetals by a certain method. It is generally obtained by melting into a homogeneous liquid and solidifying. According to the number of constituent elements, it can be divided into binary alloys, ternary alloys, and multi-element alloys. CNC machining of metal parts usually refers to CNC machining alloy, because a single element of metal cannot meet environmental requirements, therefore, usually in the field of precision machinery manufacturing, metal machining, in other words, alloy machining.

TYPE OF CNC MACHINING ALLOY

CNC Aluminum Alloy PARTS

Aluminum alloy is an alloy based on aluminum and adding a certain amount of other metal elements. In addition to the general properties of aluminum, aluminum alloys also have some specific properties of alloys due to the different types and quantities of added alloying elements. Aluminum alloy grades commonly used in CNC machining mainly include 6061 aluminum, 7075 aluminum, etc. It is widely used in aerospace, aviation, transportation, construction, electromechanical, lightweight and daily necessities and other fields.

CNC Steel Alloy PARTS

The main alloying elements of alloy steel are silicon, manganese, chromium, nickel, molybdenum, tungsten, vanadium, titanium, niobium, zirconium, cobalt, aluminum, copper, boron, rare earths, etc. Alloy steels commonly used in CNC machining mainly include: stainless steel and carbon steel. According to characteristics and uses, it is divided into alloy structural steel, stainless steel, acid-resistant steel, wear-resistant steel, heat-resistant steel, alloy tool steel, rolling bearing steel, alloy spring steel and special performance steel.

CNC Machining Copper Alloy

Copper alloy is an alloy composed of pure copper as a matrix and one or several other elements. Pure copper is purple-red, also known as red copper. Commonly used copper alloys are divided into three categories: brass, bronze, and white copper. Among them, brass is the most commonly used copper material in CNC machining. Brass is a copper alloy with zinc as the main added element. It has a beautiful yellow color that is collectively known as brass. Brass alloys with a zinc content of less than 36% are composed of solid solutions and have good cold working properties. For example, brass containing 30% zinc is often used to make bullet casings. In order to improve the performance of ordinary brass, other elements are often added, such as aluminum, nickel, manganese, tin, silicon, lead, etc.

CNC Titanium Alloy PARTS

Titanium alloy refers to a variety of alloy metals made of titanium and other metals. Titanium alloys used in CNC machining mainly include: Ti-6Al-4V and Ti-6Al-4VEli. Due to its good heat resistance, strength, plasticity, toughness, formability, weldability, corrosion resistance and biocompatibility, titanium alloy has become a commonly used metal material in the medical industry and aerospace manufacturing industry.

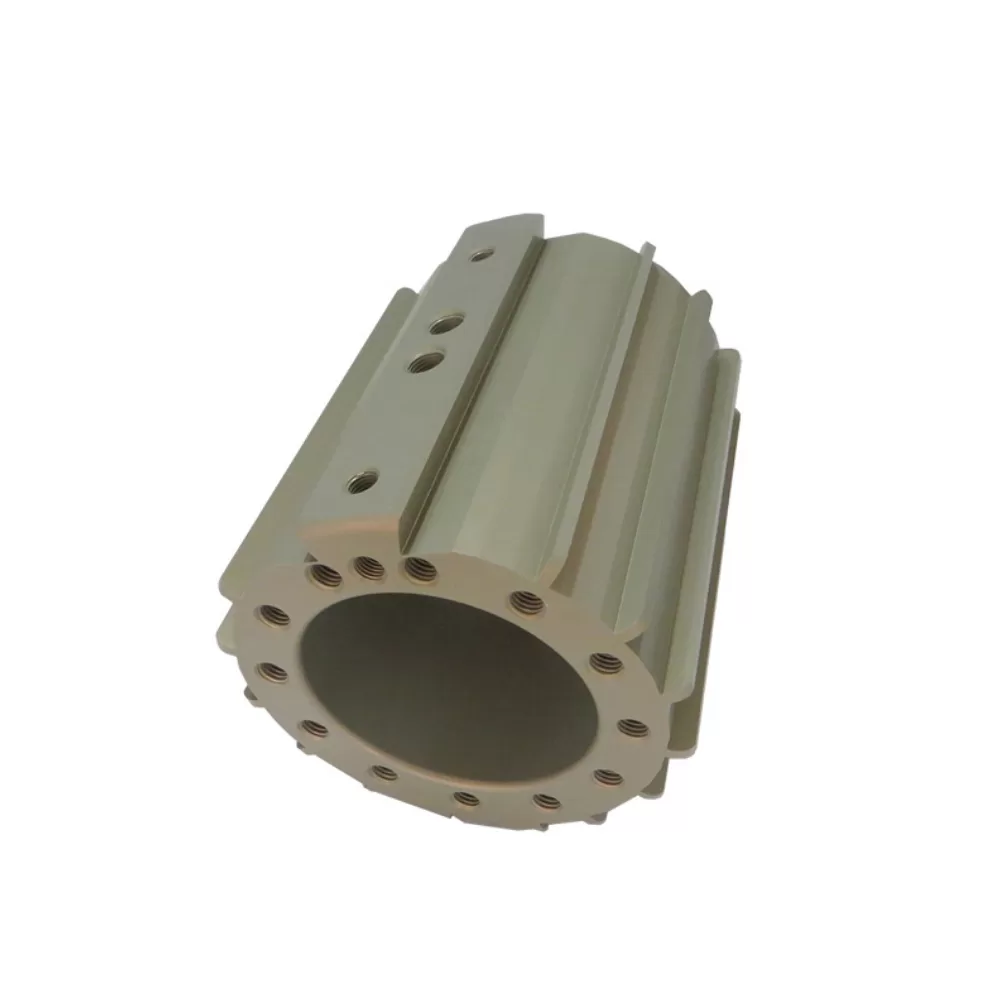

CNC MACHINED ALLOY PARTS