What is Nylon-66?

Polyhexamethylene adipamide, commonly known as nylon-66, is a thermoplastic resin generally produced by the condensation polymerization of adipic acid and hexamethylene diamine. Insoluble in general solvents, only soluble in m-cresol, etc. It has high mechanical strength and hardness, great rigidity, and is easy to be machined by CNC. It can be used as engineering plastic parts, mechanical accessories such as gears, lubricated bearing parts, and can replace non-ferrous metal materials to make machine casings, automobile engine blades and other customized non-standard parts.

Advantages of CNC machining nylon 66 parts

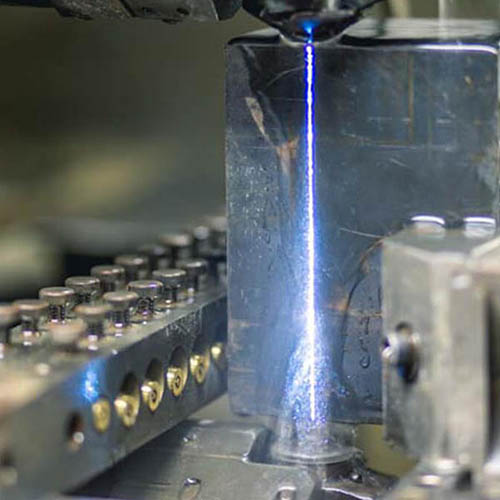

- Nylon 66 has excellent thermal, mechanical and chemical resistance. Nylon 66 parts are ideally suited to CNC turning and milling techniques.

- CNC machining of nylon 66 produces inexpensive, high-performance parts.

CNC machining nylon 66 services

| Tensile Strength, Yield (MPa) | Elongation at Break (%) | Hardness (Shore D) | Heat Deflection Temperature (°C) | Melting Point (°C) |

| 31-97 | 2-301 | 76-89 | 74-426 | 195-269 |

How to calculate the cost of CNC processing nylon 66?

Material cost of nylon 66 + machining time + number of tool changes + accuracy requirements + delivery time + outer packaging and transportation.

Finishes

- As-Machined: CNC machining of nylon 66 typically leaves an excellent surface finish. Our machinists achieve this using sharp cutting tools and appropriately high rake and relief angles.

- Sandblasting: Nylon 66 can be further smoothed by a sandblasting operation to achieve lower surface roughness.

- Dyeing: Nylon 66 absorbs liquids easily, so dyeing is a common finishing option. Use solvent dyes to dye the surface of nylon 66 parts in various colors.

Need to CNC machine nylon 66 parts?

We are the best CNC machining factory in China and can directly provide CNC machining nylon 66 services. We use CNC turning and milling machines to produce non-standard customized nylon 66 parts for you, OEM manufacturing on demand, free samples. Get a quote now.