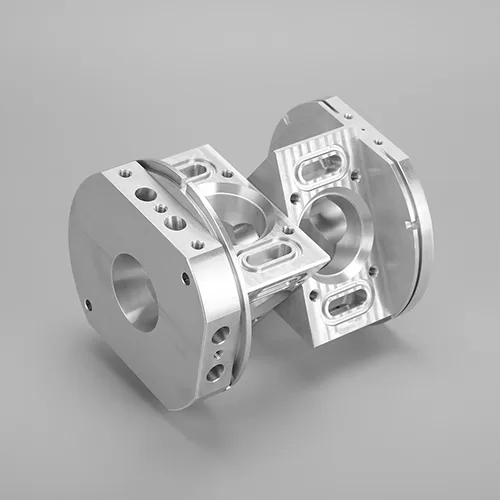

High Precision offers 5-axis CNC machining services. Our team has extensive experience and skills in 5-axis precision machining. This method is often used to manufacture complex shapes, intricate parts, and components for industries such as aerospace. Contact us for manufacturability feedback!

Why Choose Our 5 Axis CNC Machining Service?

Choosing our 5-axis CNC machining service, you will enjoy the following advantages:

- High flexibility: Our 5-axis CNC machining can produce complex parts, such as box type parts, complex surfaces, irregular parts, disc sleeve plate parts, and special processing;

- High production efficiency: The multi-directional rotation function of the 5-axis machining machine reduces the reinstallation time of the workpiece, optimizes the tool path, and significantly improves the efficiency of the production process;

- Reduce the demand for tools and fixtures: The operation mode of the 5-axis machining machine reduces the dependence on tools and fixtures, simplifies the machining process, and improves efficiency;

- Reduce consumption costs: The 5-axis machining machine reduces maintenance and tool replacement costs, while also further reducing expenses in terms of labor costs;

- Professional technical support: Our process engineers provide process technical support to help you choose between multiple processing technologies and production grade materials;

- Fast delivery cycle: We promise to manufacture high-precision CNC machining parts with high quality and fast delivery cycle;

- Advanced equipment: We have the most advanced precision CNC equipment and precision testing equipment to ensure processing quality and efficiency;

- Customized services: We offer personalized products and customized solutions to meet your specific needs.

Definition and Characteristics of 5 Axis CNC Machining

Five-axis CNC machining is an advanced CNC machine tool processing technology that can simultaneously control the movement of the workpiece on three linear axes, X, Y, and Z, as well as two rotation axes, A and B. This technology has a high degree of flexibility and accuracy, allowing us to produce parts with high complexity and strict precision requirements.

The Operating Principle of 5 Axis CNC Machining

The five axis machining technology utilizes at least five coordinate axes (X, Y, Z, A, B, three linear coordinates, and two rotational coordinates) under the coordinated control of a computer numerical control system, allowing each axis to have independent controllers and motor drive systems for synchronous motion machining. Five axis machining can also be divided into true five axis and false five axis. True five axis machining technology must have RTCP (Rotating Tool Center Point) function, which means that the machine tool can maintain the cutting point (tool center point) of the tool unchanged during five axis synchronous motion, even if the tool itself is rotating or tilting.

What Is a 5 Axis CNC Machining Center

A five axis CNC machining center is an advanced mechanical processing equipment that can achieve simultaneous linkage of five degrees of freedom, including three linear motion axes (X, Y, Z axis) and two rotation axes (A, C axis or B, C axis). This configuration allows the tool to perform complex spatial path movements relative to the workpiece, thereby being able to process parts with complex shapes and high precision requirements.

What Materials Can Be Used for 5 Axis CNC Machining?

Please refer to our CNC machining material list.

Application of 5 Axis CNC Machining Technology

Five axis CNC machining technology is widely used in multiple fields due to its ability to achieve efficient machining of complex surfaces and three-dimensional parts. Here are some specific application scenarios:

- Aerospace field: Five axis CNC machining technology is used in the aerospace field to process high-precision and high hardness parts of aircraft engines, such as turbines, blades, and casings;

- In the automotive industry, five axis CNC machining technology is used to process complex shaped parts such as cylinder blocks and crankshafts of automotive engines;

- In the field of mold manufacturing, five axis CNC machining technology is used to process high-precision parts such as injection molds and die-casting molds in the mold manufacturing field;

- In the field of medical devices, five axis CNC machining technology is also used to manufacture complex medical devices, such as artificial joints, dental implants, etc;

- In the field of artistic sculpture: In artistic creation, five axis CNC machining technology can be used to create fine sculpture works, such as marble statues, metal artworks, etc.