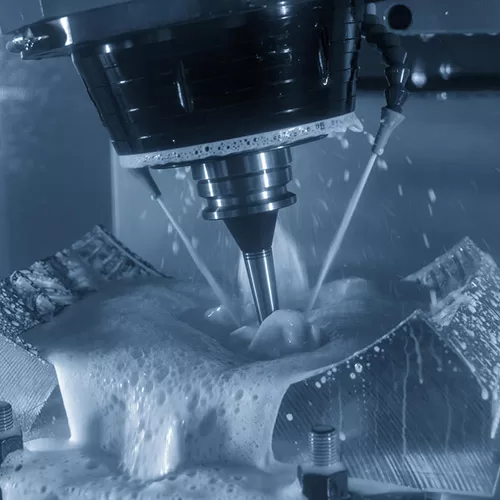

Acrylic CNC machining is the mainstream method for mass manufacturing of acrylic non-standard parts.

Xi’an Hi-Precision Machinery Co., Ltd provides high-precision acrylic CNC processing services to various industries around the world! Processing according to drawings. Receive free samples within 7 days.

We an on-demand manufacturing CNC machining company, usually uses 2-axis, 3-axis, 4-axis or even 5-axis CNC machines to processing acrylic parts. We adopt the latest diamond processing technology. This technique, known as SPDM or SPDT, can be matched with the capabilities of 5-axis micromilling to produce a range of lens and light guide types with exceptional optical quality. We will continue to improve our CNC machining services, and upgrade processing equipment and cutting tools, aiming to process various complex shapes of parts for customers.

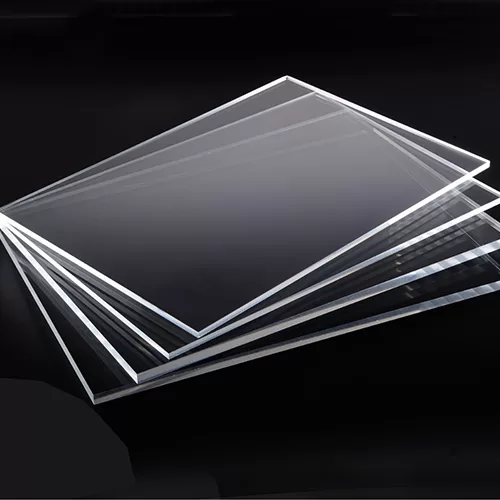

what is plexiglass?

Plexiglass, also known as acrylic, is a versatile and transparent plastic material used as a glass replacement in various applications. It comes in a variety of colors and surface patterns, offering properties such as impact resistance, UV resistance, and high optical clarity. Plexiglass is commonly used for purposes such as replacement windows, personal protective equipment, aquariums, pet enclosures, and kitchen splashbacks. It is lightweight, durable, and can be easily fabricated, making it a popular choice for many projects.

Advantages of CNC Machining Acrylic Parts:

- CNC machining techniques can create the highest precision acrylic parts with a good surface finish.

- Although CNC machining is a material reduction movement, its own digital manufacturing and artificial intelligence features can save acrylic material waste to the greatest extent.

- CNC machining acrylic can produce acrylic parts in batches and ensure the same quality of the same batch of goods.

- CNC machined acrylic supports personalized customization and rapid prototyping.

Skills of CNC machining acrylic:

- Stable feed speed. This is done to prevent the knife from staying in the same position too much and generating heat from the friction of cutting. If the feed rate is too slow, the chips will start to re-weld to the part and will destroy the surface finish and accuracy of the acrylic part.

- Choose the right knife. When drilling acrylic, the drill bit must have a much smaller tip angle than a standard drill bit. It should be 60 degrees, not 120 degrees. It has also been improved for better chip removal.

- Use the coolant at the lowest temperature. Many acrylic sheets need to be cooled before processing. This allows for better chip removal and prevents friction that can lead to overheating and fires. Other than that, you can use some standard coolants, but if you have oils, make sure they don’t react with the acrylic.

- Grinding and polishing. After achieving the desired accuracy and shape, parts always need to be ground and polished. Typically this is done using a smaller grit polishing tool followed by a linen towel coated with polishing paste. In addition, there are some chemical polishing methods, such as fumigation.