Quality testing equipment is a must-have machine for every CNC machining factory. We are a professional CNC machining company that complies with ISO9001 quality management system. Quality inspection is a procedure that must be performed before delivering parts, and it is also an important step in ensuring product quality to our customers.

Our Quality Testing Equipment

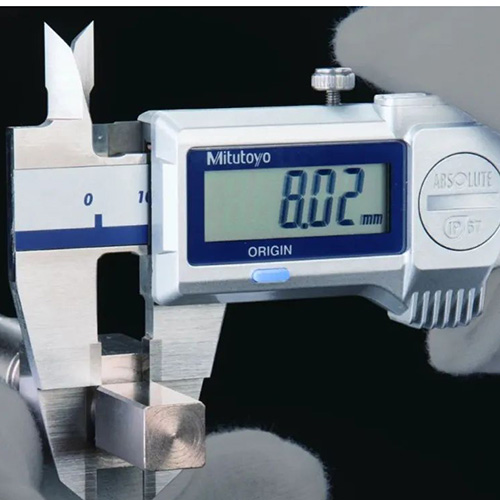

Vernier caliper is a measuring tool for measuring length, inner and outer diameter, and depth. It can be used to measure the inner diameter, outer diameter, length, width, thickness, depth and hole spacing of parts. It has a wide range of applications and is a universal energy tool. This is also the cheapest quality inspection equipment for CNC machining workshops.

The spiral micrometer, also known as micrometer, spiral micrometer, and centicaliber, is a more precise tool for measuring length than a vernier caliper. It can measure length accurately to 0.01mm, and the measurement range is several centimeters. Our CNC machining shop uses electronic micrometers to measure part outside diameters. Electronic micrometers are also called digital micrometers. The measurement system uses grating length measurement technology and integrated circuits.

The image measuring instrument is based on CCD digital images and relies on the powerful software capabilities of computer screen measurement technology and spatial geometric operations. After the computer is installed with special control and graphic measurement software, it becomes the measurement brain with the soul of the software and is the main body of the entire equipment. It can quickly read the displacement value of the optical ruler, and obtain the desired results instantly through software module calculations based on spatial geometry; and generate graphics on the screen for the operator to compare images and images, so that the operator can intuitively distinguish Possible deviations in measurement results. The image measuring instrument is a high-precision instrument composed of a high-resolution CCD color lens, a continuously variable magnification objective lens, a color display, a video crosshair display, a precision grating ruler, a multi-function data processor, data measurement software and a high-precision workbench structure. Optical image measuring instruments.

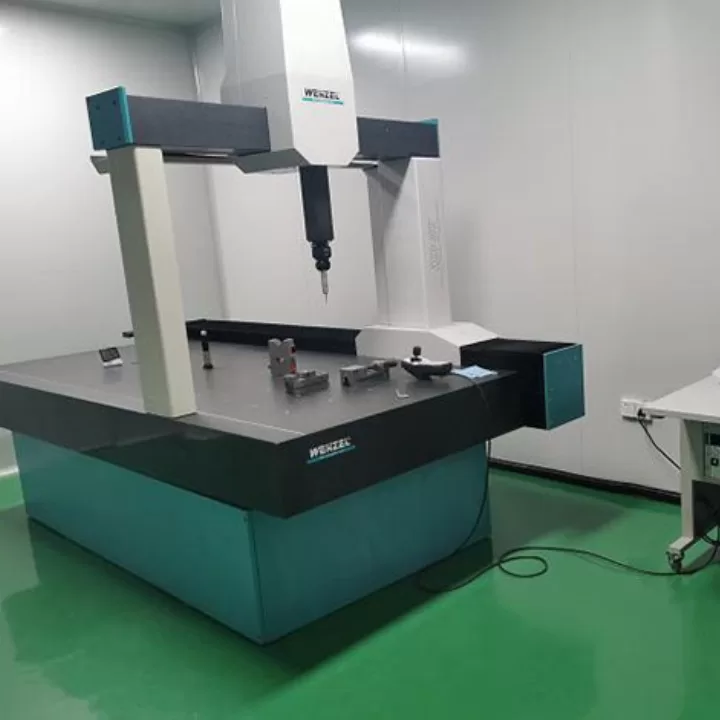

Coordinate measuring machines are widely used in machinery, electronics, instrumentation, plastics and other industries. The three-dimensional coordinate measuring machine is one of the most effective methods of measuring and obtaining dimensional data, because it can replace a variety of surface measurement tools and expensive combination gauges, and reduce the time required for complex measurement tasks from hours to minutes. This is Effects that other instruments cannot achieve. CMM can be divided into contact measurement, non-contact measurement and combined contact and non-contact measurement according to the measurement method. Contact measurement is often used to measure CNC processing products, pressed molded products, metal films, etc.