The “China brass CNC turned mechanical parts hydraulic accessories” displayed on the product page belongs to pre-sale products. If you need machining services, please click “Contact us” on the product page and send your drawings to our mailbox for manufacturability feedback. Once we confirm your order, you can get the sample within 7 days.

Our team has rich manufacturing experience in NC machining. In addition to CNC machining, our company also provides drilling, cutting, wire cutting, forging, die casting, mold processing, grinding and other manufacturing processes. Our CNC machinists will reasonably choose the corresponding manufacturing method according to your project requirements. In addition, the accuracy of products can be implemented according to customer requirements. Our factory can meet almost all types of customized processing requirements, and powerful 3-axis, 4-axis and 5-axis CNC machine tools can manufacture any non-standard special-shaped mechanical parts with simple or complex structures. Send your design documents to our mailbox, and you can receive our quotation, delivery time and manufacturability feedback of NC machining flanges within a few hours. Whatsapp: +86 18991129810

Brass is a kind of high-quality copper alloy, which has a long history in various processing applications. Because of its many advantages, it has developed into an important part of professional parts manufacturing enterprises. Nowadays, brass is often processed by CNC to produce various items, including brass gears, pipes and fittings, bearings, bell mouth fittings and so on. Components made of brass are used in various fields, including machinery, automobile, electricity and musical instrument production.

For more than ten years, we have been serving many key industries, including medical care, automobiles, ships, aerospace and so on. And we are good at creating high-precision brass parts. We have advanced CNC machining technology and various grades of brass materials. Our small batch production mode can deliver your order quickly without the burden of large-scale expenditure, thus balancing cost and efficiency. In our machining service, you can always customize the size, tolerance, design, color and other attributes of parts. We will check the quality of products before each delivery. Our service also has many advantages, including cost-effectiveness, speed and versatility. We work closely with our customers to understand their needs and provide them with customized solutions to meet their specific needs. We can also provide free advice on CNC turning and milling parts and long-term after-sales service.

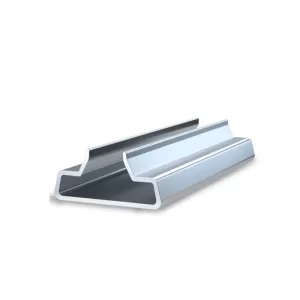

China Brass CNC Turned Mechanical Parts Hydraulic Accessories

| Weight | 0.2 kg |

|---|---|

| Dimensions | 0.2 × 0.3 × 0.4 in |

| MOQ | 10pcs |

| Payment Method | L/C, T/T, Western Union, MoneyGram |

| Brand | OEM/ODM |

| Delivery Time | About 2 Weeks |