We will introduce 5 axis machining center, as well as the 5 axis CNC machining services we provide to various industries around the world, as well as how to find a 5 axis CNC machining factory.

What is 5 Axis CNC Machining Center?

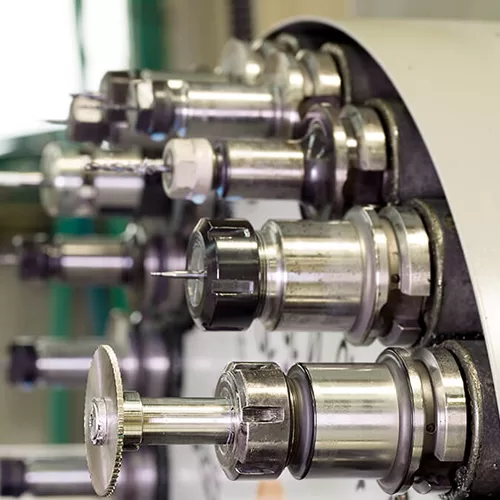

The five-axis linkage machining center, also called the five-axis machining center, is a high-tech, high-precision machining center specially used for processing complex curved surfaces. This machining center system is very important to the global aviation, aerospace, military, scientific research, and precision instruments. , high-precision medical equipment and other industries have a decisive influence.

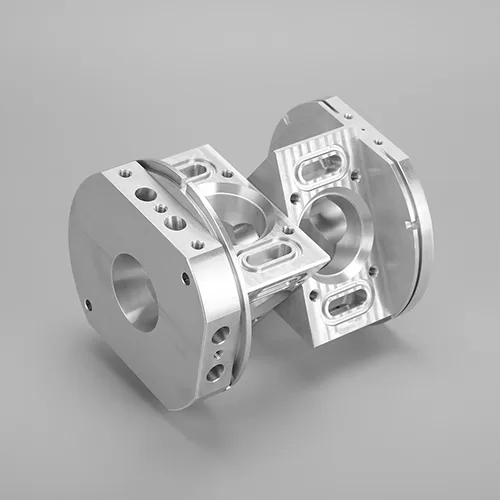

The five-axis linkage machining center has the characteristics of high efficiency and high precision, and complex processing can be completed in one clamping of the workpiece. It can be adapted to the processing of modern molds such as automobile parts and aircraft structural parts. There is a big difference between a five-axis machining center and a pentahedral machining center. Many people do not know this and mistakenly regard the pentahedral machining center as a five-axis machining center. The five-axis machining center has five axes: The “pentahedral machining center” is similar to the three-axis machining center, except that it can process five faces at the same time, but it cannot do special-shaped processing, punching oblique holes, cutting bevels, etc.

The commonly used simulation software for five-axis machining centers is called PITAGORA. What does this software do? Usually, when we operate five-axis equipment for processing, we need to program or make drawings in advance. Due to manual operation problems, program errors may occur, which will inevitably lead to collision events, which may damage the equipment. The PITAGORA software is used to simulate actual processing. It can predict in advance whether there are errors, thereby reducing the accident rate to a minimum and ensuring equipment safety!

Our 5 Axis Machining Service

High-precision offers a wide range of customized online CNC machining services, including 3, 4 and 5-axis CNC milling and turning. Our company has advanced equipment and an experienced team, able to provide one-stop services from design, rapid prototyping to mass production. Ensure that the machining process complies with the ISO 9001:2015 quality management system to achieve high-precision machining, and the tolerance can be controlled within ±0.02 mm.

In short, our 5 axis CNC machining service has become the preferred solution in many high-end manufacturing fields with its high precision, high efficiency and ability to process complex parts.

How to Find a Factory With 5 Axis CNC machine?

To find a five-axis CNC machining factory, you can consider the following ways:

- Online search: Use search engines to find manufacturers that provide five-axis CNC machining services. For example, Xi’an Hi-Precision Machinery Co., Ltd provides customized online CNC machining services including five-axis CNC milling and turning.

- Industry exhibitions and conferences: Attend relevant manufacturing or machining industry exhibitions and conferences, which usually have various CNC machining service providers.

- Professional B2B platform: Search on professional B2B platforms, such as Alibaba International Station, Made-in-China.com, etc., which gather many machining service providers.

- Industry forums and communities: Join relevant industry forums and communities to find suitable five-axis CNC machining factories through information exchange within the community.

- Direct contact: If you already know the name or brand of certain factories, you can directly visit their official website or contact them directly to get service quotes and details.

- Word-of-mouth recommendation: Find a reputable five-axis CNC machining service provider through recommendations from peers or partners in the industry.

It is worth noting that many companies claim to have 5 axis CNC machines in their factories, but in reality, their 5 axis CNC machines are fake. But this is not the most important thing, the most important thing is whether the quality of the products they deliver meets your requirements.

Make sure when choosing a CNC machining company that you consider their equipment capabilities, machining accuracy, material handling range, quality control system, and past machining cases to ensure that they can meet your specific needs.