What is the future development trend of CNC machining? Some people say it must be 9 axis CNC milling. Five-axis linkage CNC machine tools have long been known to people and are widely used in production. In our impression, “the more axes, the more powerful the machine tool is.” Five-axis machine tools can complete pentahedral machining of workpieces in one clamping, so can 9 axis CNC machine really be more powerful?

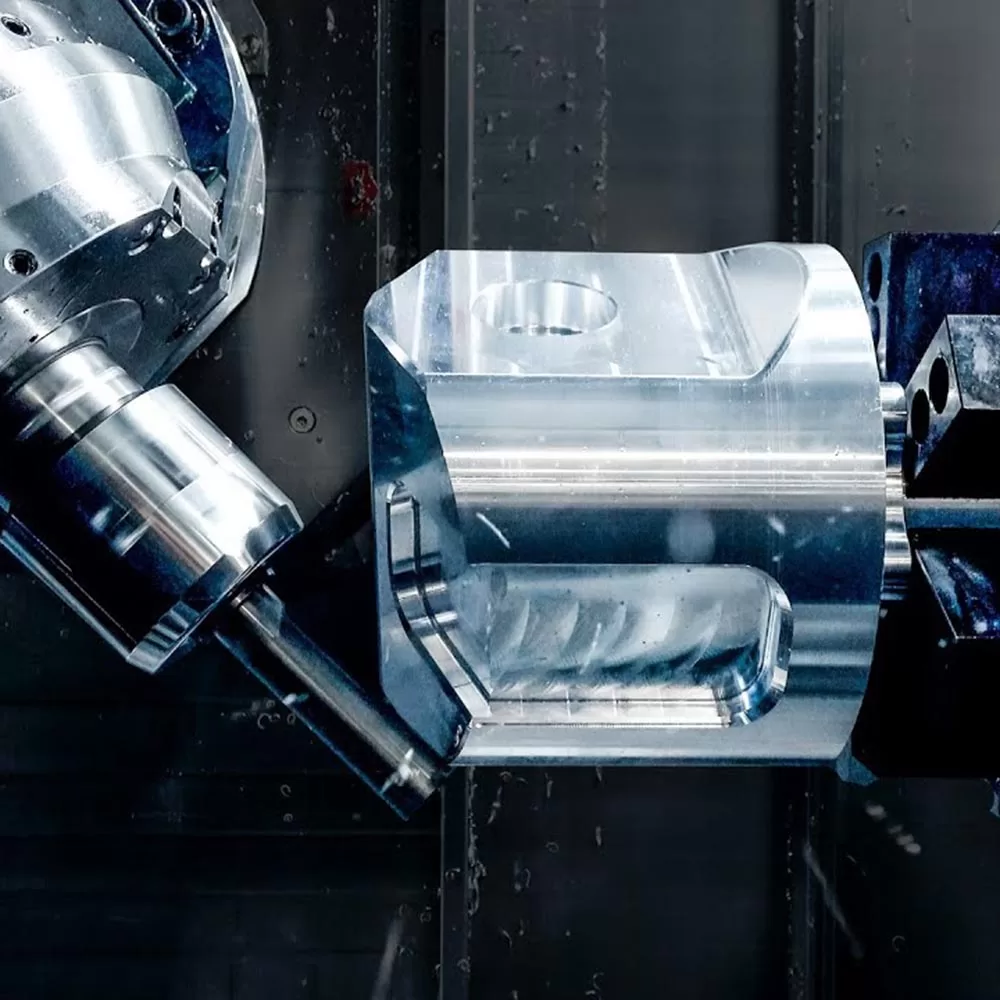

First, we need to understand what CNC milling is. CNC milling is a manufacturing process based on computer numerical control technology. The basic principle is to input the data in the design drawings into the computer program and convert it into machine instructions, so that the machine tool can automatically move the tool and workpiece, and control the workpiece for cutting. Currently, 5-axis CNC milling machines are the most advanced CNC machining equipment.

CNC machining has revolutionized manufacturing, and its continued development has allowed it to make significant progress with every challenge it encounters.

Why Is 9-Axis CNC Milling the Future of the CNC Machining Industry?

9-axis CNC milling involves a large number of work axes and is particularly suitable for complex and large-scale parts processing. But it is still based on 5-axis CNC machine tools. With the continuous development of computer technology and control systems, CNC milling technology has been constantly updated and upgraded in terms of functions and processing capabilities, providing more powerful support for product design, manufacturing and precision processing. For example, in the fields of aviation, aerospace, automobiles, machinery manufacturing, etc., 9-axis CNC milling is required to manufacture a large number of complex parts. Because it can efficiently complete the processing of various complex shapes, it has been widely used.

In addition, 9 axis CNC milling technology also has a high degree of automation. In terms of automation, CNC milling machines are more advanced than traditional digital display milling machines and have more precise hardware control. After being connected to the production line, it can form an intelligent assembly line production to efficiently meet the needs of small batch and multi-variety production. This is very important for enterprises to reduce labor costs, improve production efficiency and competitiveness, while maintaining a certain degree of product accuracy and stability. This is exactly the capability that the CNC machining industry will need in the future.

In conclusion, the application of 9 axis CNC mill machining technology has become an important part of the manufacturing industry. It has a high degree of automation, precision and production efficiency, and can play a vital role in the production process of parts. At the same time, we also need to pay attention to the improvement and optimization of programming. With the further development of technology in the future, 9 axis CNC milling technology will be more advanced, precise and widely used in various fields.

When working with 9-axis CNC milling, programming is key. Programming needs to take into account the machining accuracy requirements, tool selection, cutting speed and cutting depth and other parameter settings. The correctness of programming directly determines the quality and processing efficiency of the final product. Therefore, for the application of 9 axis CNC machining technology, it needs continuous development and improvement in terms of personnel training and technology update.