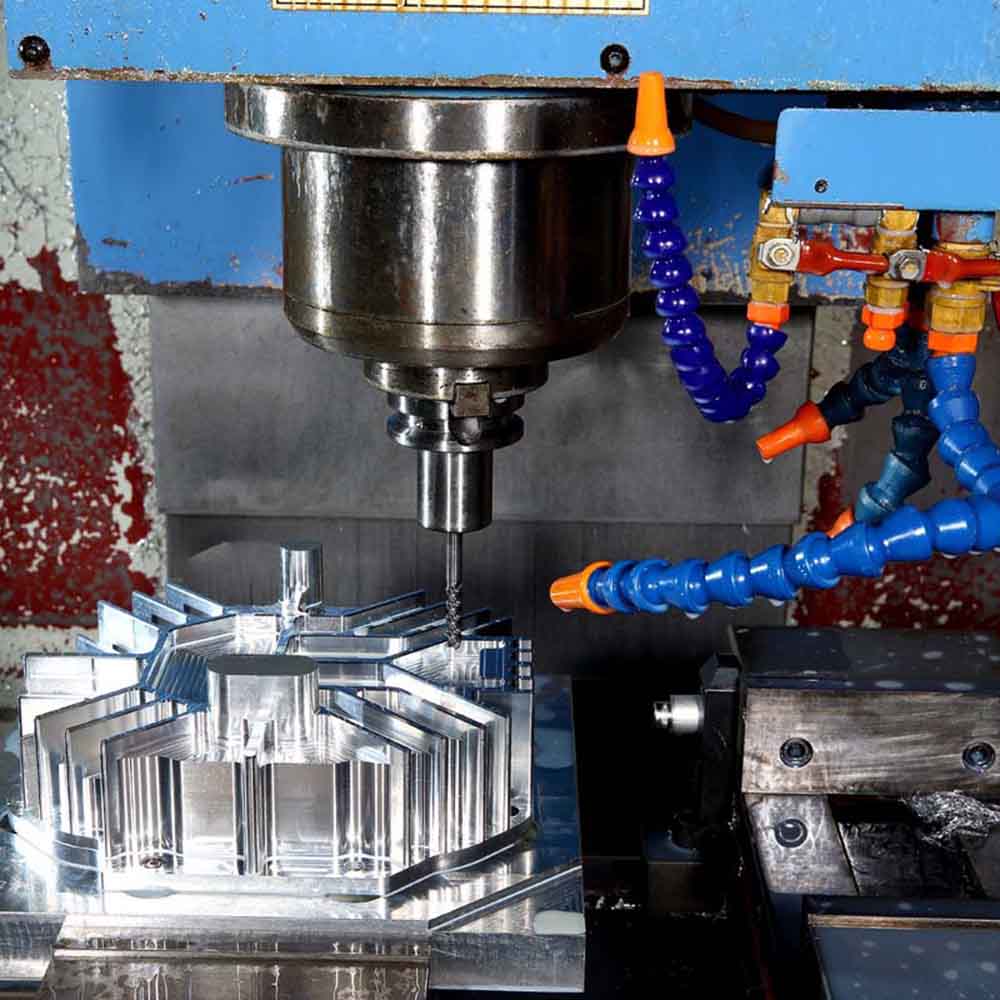

A small CNC mill machine is for the individual fabrication hobbyist who needs to do small batches or one-piece workpiece machining at home. So, if you want to buy a small CNC milling machine dedicated to machining aluminum parts, how should you choose?

If you are looking for a small CNC milling machine suitable for machining aluminum parts, you can refer to the following aspects:

- Equipment power: Under normal circumstances, the power required for processing aluminum is not too large, generally between 2.2kW-5.5kW. If it is too large, it will be wasteful and increase the cost of equipment.

- Machining accuracy: Aluminum is a relatively soft material, which is prone to problems such as thermal deformation and plastic deformation. Therefore, it is very important to choose a micro CNC milling machine with high processing accuracy.

- Equipment stability: In order to ensure the processing effect and safe operation, it is necessary to choose a small CNC milling machine with stable structure, stable operation and good precision retention.

- Control system: The control system also has a great influence on the processing effect. It is recommended to choose a common brand of CNC system, such as Fanuc, Siemens and other internationally renowned brands.

- Tool: It is necessary to choose a tool suitable for aluminum material machining. Aluminum is a relatively soft material. When using tools, care should be taken not to affect the life of the equipment and the processing effect due to excessive wear and overload cutting. Usually end mills or flat cutters can be used.

- Cutting parameters: When setting cutting parameters, it is necessary to pay attention to avoid excessive cutting, otherwise it may damage the tool and leave scratches. When selecting processing speed, feed rate and depth of cut, refer to the data provided by the manufacturer. At the same time, aluminum chips and coolant should be cleaned up in time during the processing to ensure the cutting effect and working environment.

- Heat dissipation problem: Aluminum is a material with good conductivity, which will absorb the heat energy generated during cutting. If the heat cannot be dissipated in time, the temperature will rise too high and the machining accuracy will decrease. Therefore, when using a CNC milling machine to process aluminum materials, in addition to considering the tool and cutting parameters, it is also necessary to pay attention to the heat dissipation performance of the equipment. Measures such as air-cooled radiators or water-cooled radiators can be used.

- Price factor: For small CNC milling machines, price is a factor that must be considered. You need to choose a cost-effective device according to your needs and actual situation.

In short, the small CNC milling machine for machining aluminum parts should have good processing accuracy, stable structure, stable operation, strong accuracy retention, and moderate price. When choosing, it is recommended that you learn more about the products on the market, compare the parameters and prices of different brands and models, and choose a device that is most suitable for you.

If your budget is not enough to buy the cheapest CNC milling machine, please don’t blindly compromise and buy a cheap but crap milling machine as a substitute, it’s just a waste of your money. The best way is to buy a used CNC milling machine and make sure it is working properly, or you can consider working with a CNC machining company and buy a professional CNC milling services to help you produce the aluminum products you want.