CNC machine monitoring software can achieve the purpose of tracking CNC machine tool performance, production efficiency and resource analysis. Many professional CNC processing factories will equip their computers with such softwares. So today, there are countless CNC processing monitoring software in the world, so do you know which software is the best CNC processing monitoring software in 2023?

The workshop monitoring system monitors the efficiency and power consumption of factory operations and production lines in terms of OEE (Overall Equipment Effectiveness Level) and OPE (Overall Plant Effectiveness Level). With its added functionality for personnel tracking and automatic cost price calculation, it is an excellent tool for cost leadership in manufacturing.

The system uses smart card readers and sensors. All machines, operators, molds and/or products can be identified, so the efficiency and energy consumption of any combination of jobs is recorded. The Auxiliary Equipment Monitor can be used to monitor the energy consumption of any other machine (unit) or department within the plant.

When a CNC machine (or workstation) is running normally, but it is down, it will cause business losses. Therefore, it is especially important to minimize the frequency and duration of downtime. There are many reasons for unplanned downtime, but most cannot be blamed on the operator. The content of this article is to introduce the detection of alert credentials that allow downtime to be generated.

- Flexible System Notifications

- Control when an alert is issued

- instant notification

Your shop may need to have different groups of CNC lathes follow different work schedules and switch between that schedule on a daily, weekly or monthly basis. The function of our module has the characteristics of simple operation and flexible control.

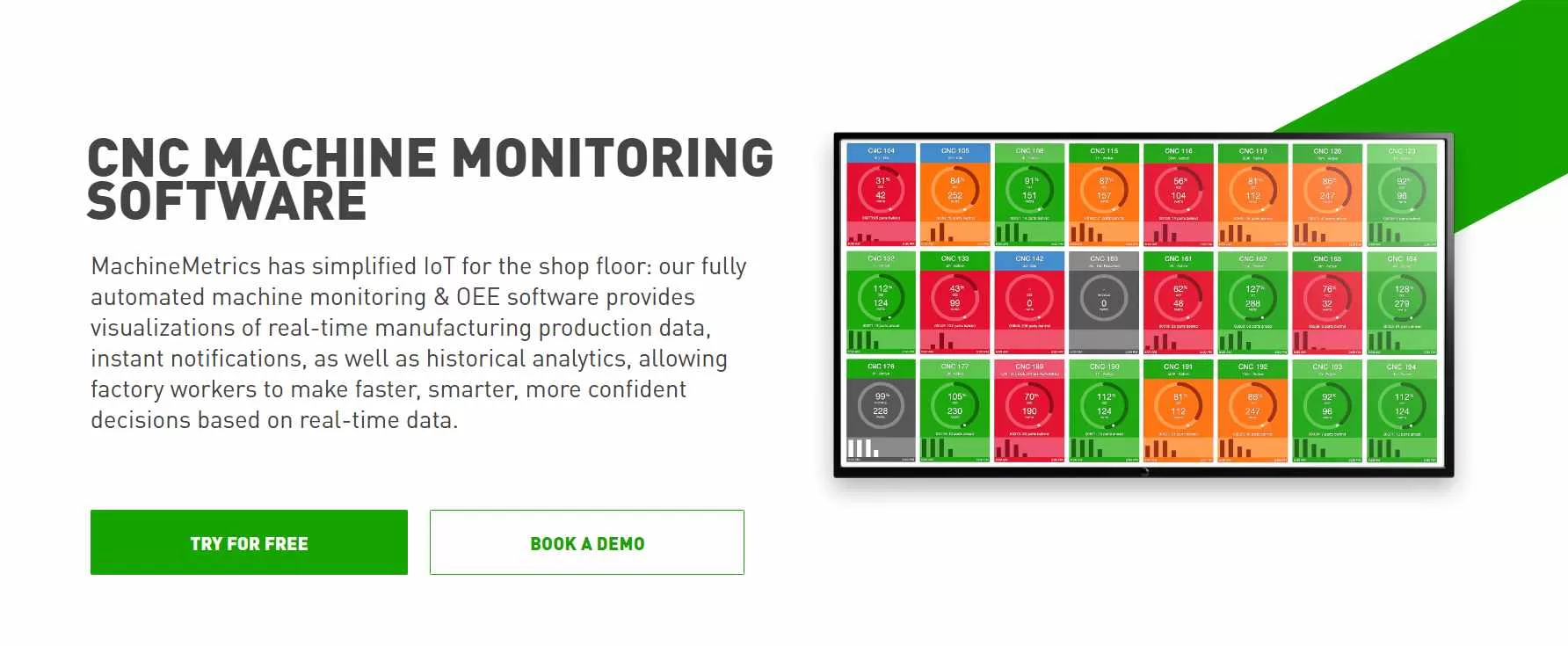

- Real-time monitoring: It can monitor the running status of CNC machine tools in real time, including various indicators of machine tools, processing data, etc.

- Data collection: CNC machine tool monitoring software can collect, process and analyze processing data in the production process.

- Fault diagnosis: The monitoring software can automatically detect and diagnose machine faults, and give an alarm at the first time.

- Production plan management: According to the production task, the processing plan and plan can be formulated, and the production progress can be tracked and managed.

- Equipment maintenance management: It can manage and schedule the maintenance cycle and maintenance plan of the machine tool, effectively improving the service life of the machine tool.

- Quality control: The monitoring software can also perform quality control of production process data to ensure that the quality of the product meets the standards or customer requirements.

- Remote monitoring: Some CNC machine tool monitoring software also supports remote monitoring, so that production managers can remotely view the production status of machine tools anytime, anywhere.

Share the download link of CNC machine tool monitoring software for free here, click below to download the installation package: