As we all know, CNC machining is currently the most advanced metal precision machining technology. And the application of CNC machining in the field of transportation is very widely. Whether it is a car, a van, a large truck driving on the road, or a large bus used for public transportation, a truck, a high-speed rail, an airplane, etc., in the whole machine manufacturing process, CNC machining technology will be used to complete the processing of parts.

What Are the Applications of CNC Machining in Transportation?

Materials that can be used in the transportation industry can basically be processed on CNC machine tools, such as common aluminum alloys, stainless steel, brass, titanium alloys, etc. You can set plastic, carbon fiber and other materials to be cut by CNC machine tools. These materials can be precisely manufactured into the parts on the drawing through CNC cutting. The most representative application of CNC machining in the transportation field is customized processing and modified auto parts. Whether it is screws and nuts, washers, or bushings, almost all can be processed by CNC.

So next, let’s take a look at the three most representative applications of CNC machining in the transportation field:

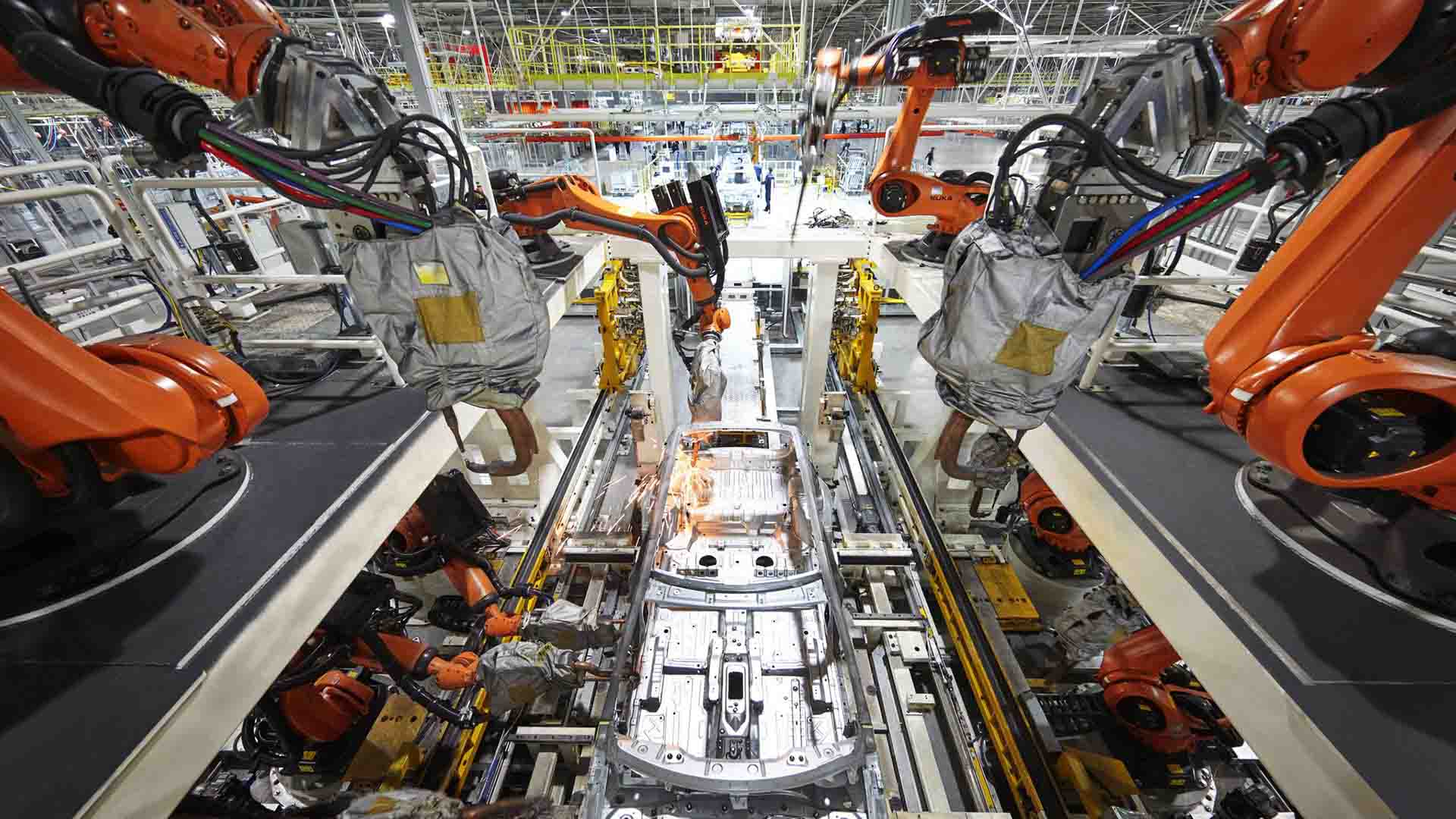

CNC Machining Car Body Kit

Cars are currently the most popular form of transportation. CNC machining is also widely used in automobile manufacturing. Use CNC controlled lathes, milling machines and machining centers to process a variety of automotive parts, including body block and cylinder head machining, nuts and screws, etc. The advantages of using CNC machining in the automotive industry are reflected in the production capacity of complex precision parts, improved production timeliness, and ensuring the consistency and repeatability of parts manufacturing. CNC machining is used to manufacture many small body parts such as holes, roundness, brake components, gears, shafts, turbine blades and suspension components. The technology’s high precision and accuracy make it ideal for producing critical components such as body blocks and custom car parts. While the cost of professional CNC machines can be high, individuals or small businesses have several options, such as using a used CNC machine or finding a CNC machine shop to help them complete some precision machining tasks.

CNC Machining Custom Truck Parts and Accessories

Trucks are vehicles primarily used for transporting goods. CNC machining is widely used to produce custom truck parts and accessories with high precision and a wide range of functionality. In truck manufacturing, CNC lathes, milling machines, and machining centers are still used to create a variety of truck parts, such as engine blocks, cylinder heads, gears, axles, and suspension components. The technology is capable of producing complex and precise parts, helping to improve production efficiency and product quality. Additionally, CNC machining can be used to create custom automotive parts, including engine adapters, steering bushings, and a variety of other parts for trucks and buses. The process involves using advanced CNC equipment to manufacture parts that meet precise specifications and high standards of reliability and performance. Overall, CNC machining plays a vital role in the production of custom truck parts and accessories, capable of manufacturing a wide range of components with exceptional precision and quality.

CNC Machining of Aircraft Parts

CNC machining is widely used in the aerospace industry to produce a variety of aircraft parts with high precision and accuracy. This includes manufacturing complex and sophisticated components that meet civil and military aviation needs, such as engine parts, avionics systems, control surfaces and improved engine mechanisms. The aerospace industry requires extremely high precision in parts, and CNC machining plays a vital role in meeting these requirements. The process involves using advanced CNC equipment to manufacture parts that meet precise specifications and high standards of reliability and performance. CNC machining is also critical for machining lightweight metals such as aluminum and titanium, which are critical to aircraft performance. In addition, CNC machining helps reduce the cost of manufacturing aerospace products by minimizing waste and streamlining production, while also improving the quality and consistency of aerospace part processing. The use of high-quality materials and advanced technologies, such as five-axis CNC machine tools and artificial intelligence-assisted CNC machine tools, further enhances the capabilities of CNC machining in the aerospace industry.

CNC Machining Boat Parts

CNC machining of ship parts, the most representative one is the propeller. A propeller is a device that converts the rotational power of an engine into propulsion by rotating blades in air or water. There can be two or more leaves connected to the hub. CNC-processed ship propellers can not only achieve customized processing, non-standard customization, and special-shaped processing, but also ensure accuracy and quality.

The application of CNC machining in the transportation field is not limited to this. If you need custom processing of precision metal parts for the transportation industry, please contact us. We are the best CNC machining factory in China and can process various precision and complex non-standard special-shaped parts according to drawings.