CNC milling of thin plate parts has problems such as low stiffness and poor processing technology. Under the action of cutting force, clamping force, cutting chatter and other factors, processing deformation is prone to occur, and it is difficult to control processing accuracy and improve processing efficiency. Processing deformation and processing efficiency issues have become the main problems faced when CNC milling thin-walled parts.

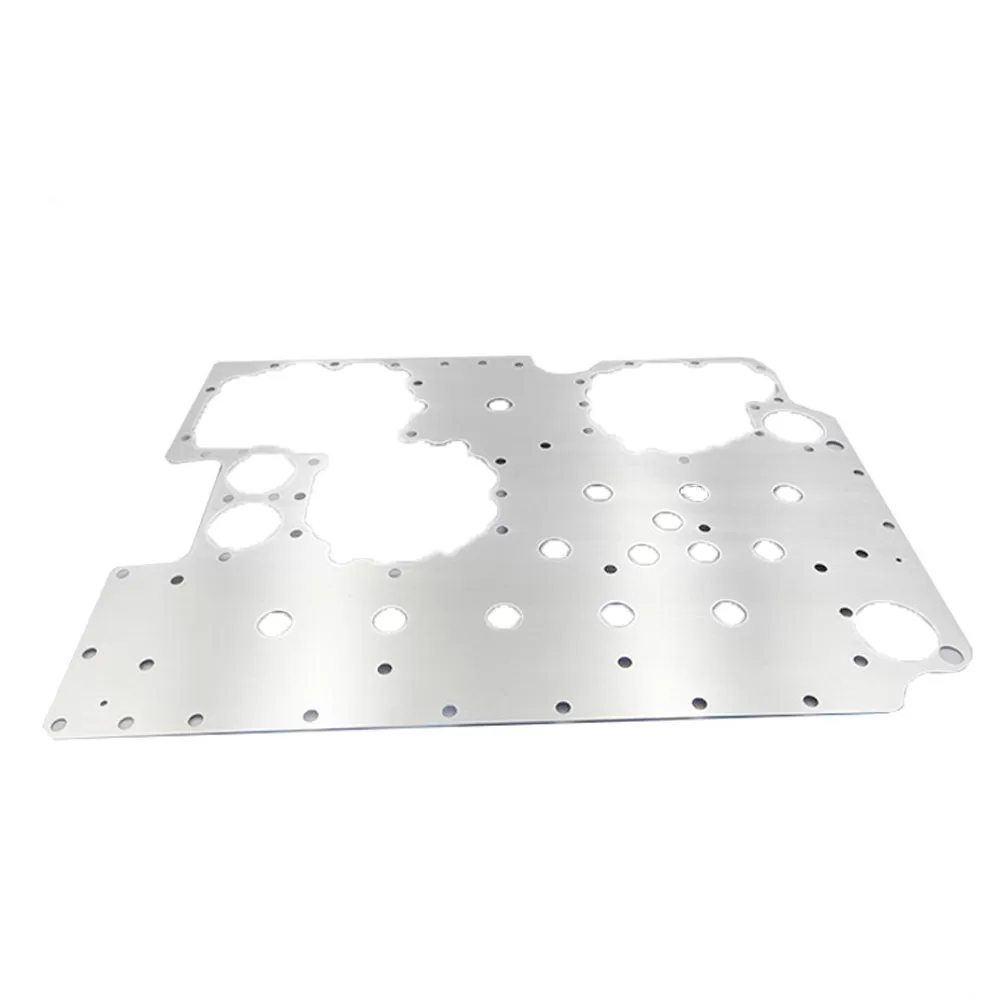

Thin plate parts are commonly used in aerospace industry products, military products and medical equipment. Their structures are not complex and the accuracy requirements are not too high. However, due to poor stiffness, they are prone to deformation during the clamping process and under the action of cutting forces. , resulting in out-of-tolerance dimensions and parts milling through. Moreover, the processing efficiency is low and the processes are numerous. In particular, it takes a long time for the fitter to level the parts and it is easy to rework.

Through research on the processing of thin plate parts, we have found a common processing method that can promote the development of cutting processing technology for thin plate parts, ensure processing quality, shorten production preparation time and processing cycle, reduce production costs, and improve productivity.

Problems in CNC milling of thin plate parts

Thin plate parts have simple structure, large volume, low relative stiffness, and poor processing technology. Under the action of cutting force, clamping force, cutting chatter and other factors, processing deformation is prone to occur, and it is difficult to control processing accuracy and improve processing efficiency. Processing deformation and processing efficiency have become the main problems faced in the processing of thin-walled parts.

When processing thin plate parts, the parts will be twisted or warped, and these deformations are irregular deformations with great randomness. After processing, the parts are severely deformed and cannot meet the needs.

How to solve the quality problems faced by CNC milled thin plate parts?

Improved vacuum suction cup. The vacuum suction cup originally consisted of a series of small holes. Instead, the holes were milled through with a milling cutter, slightly lower than the other surfaces by 0.5mm. On the one hand, it is difficult to block the hole. On the other hand, the vacuum suction cup is a whole when sucking, changing from point contact to surface contact.

Since the entire thin plate is uneven and irregular, the finite element idea is used to break it into parts. Divide the entire board into countless small pieces. For each small piece, the smaller the division, the higher the flatness. Use the CNC machine tool’s own probe to detect different positions of the part according to processing needs, obtain the true state of the part in the clamping state, and record the detection data.

According to the structural characteristics and process characteristics of thin plate parts, the number of teeth of the processing tool should not be too many. Generally, 2 to 3 teeth are selected. The geometric parameters of the tool should be selected from the perspective of reducing the cutting force. Tools with large front and rear angles should be selected; the helix angle should be At 30° to 45°, an excessive helix angle will increase the axial force, while an excessively small helix angle will increase the difficulty of chip removal.

During the machining process, various cutting fluids were tested and it was found that using kerosene can reduce the generation of burrs and has less impact on the fixture.

High-speed milling is used to machine this part. Through experiments, when the rotation speed is limited to about 15000r/min, the noise is smaller (related to factors such as machine tools) and the tool is not easy to break. When the rotation speed is 15000r/min, the feed amount is selected to be 0.05mm/r, which translates into a feed rate of 750mm per minute.

High-speed milling requires not only high rotational speed, but also fast tool feed speed. When programming, it is necessary to try to process the program into a program suitable for high-speed milling, and the machine tool should be in a relaxed state during the processing, that is, the X-axis and Y-axis do not self-lock, so that the machine tool can move smoothly.

According to the above idea of dividing the thin plate into countless small pieces, a depth can be used for each small piece during processing. For other small pieces, if the depth changes, local oblique milling can be used, so that the entire thin plate can be processed. Say, there are some diagonal transitions, but the depth relative to the surface is much improved. Use a CNC probe to detect the depth of different segmented parts, and use VB6.0 to compile the CNC conversion program for the detection results.

After the part was processed using this method, all indicators met the requirements, proving the correctness of the test method and conclusion.

Based on high-speed CNC milling technology, this article reduces the clamping deformation and processing deformation of large thin plate parts through a series of research work and process experiments, effectively controls the deformation, and improves processing quality and processing efficiency.