For beginners who are just starting to operate CNC machine tools, one of the most important lessons is to learn about the types of CNC milling cutters. Today, we will introduce the 8 common types of CNC milling cutters and their applications.

What is CNC Milling Cutters?

CNC milling cutter is a rotary tool with one or more teeth used for milling. During operation, each tooth cuts off the excess of the workpiece intermittently in sequence. Milling cutters are mainly used in the processing of steps, grooves, forming surfaces and cutting off workpieces.

These CNC Milling Cutters

- Flat head milling cutter;

- Ball end mills;

- Flat end milling cutter with chamfer;

- Forming milling cutter;

- Chamfering knife;

- T-type knife;

- Gear milling cutter;

- Rough leather milling cutter.

Application of Different Milling Cutters

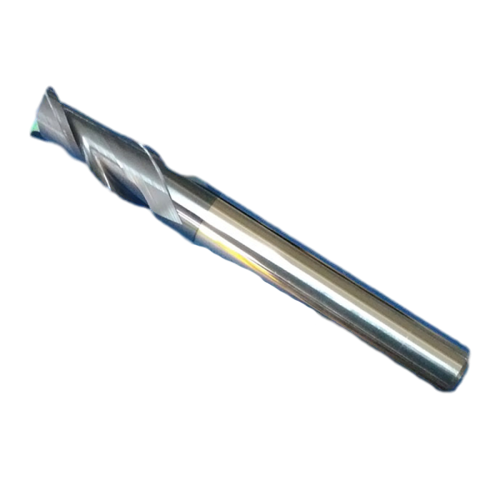

Flat Head Milling Cutter

A flat end mill is a cutting tool widely used in milling processes and is characterized by its flat bottom geometry that provides sharp, straight edges in the machined workpiece. It is an integral part of manual and CNC milling machine operations, rotating at high speeds to cut and shape metals, plastics, and other materials. The flat bottom of the milling cutter provides a high level of precision and is suitable for creating slots, trimming edges, and producing fine finishes on flat surfaces.

Ball end mills

A ball end mill is a tool with a ball-like blade that is mounted on a milling machine and is used to mill various curved surfaces and arc grooves. A ball end mill is also called an R cutter.

Ball end mills can be used to cut mold steel, cast iron, carbon steel, alloy steel, tool steel, and general iron materials. Ball end mills can operate normally in high temperature environments.

Flat End Milling Cutter with Chamfer

Flat head milling cutter with chamfer can be used for rough milling to remove a large amount of blank, and can also be used for fine milling of small chamfers on flat surfaces (relative to steep surfaces).

Forming Milling Cutter

The milling cutter whose cutting edge profile is designed according to the workpiece profile is called a profile milling cutter. Like the profile turning tool, it can ensure the dimensional accuracy, shape consistency and high productivity of the workpiece being processed. Profile milling cutters are widely used in production, such as processing straight chip grooves and spiral chip grooves of various tools, especially in turbine blade processing. Profile milling cutters can be divided into two types according to their tooth back form: pointed tooth profile milling cutters and shovel tooth profile milling cutters.

Chamfering Knife

Countersink is also called chamfering tool. It is a drill used for countersinking conical countersunk holes. It can be used to deburr, chamfer, and dig countersunk holes at the hole mouth. The premise is that there must be a guide hole before subsequent processing. The taper conical hole is larger at the top and smaller at the bottom. To place a taper flat head screw, it is necessary to process the countersunk hole and the taper hole. Trimming and deburring the hole mouth is to lightly trim the edge of the hole mouth. Remove the corners of the hole mouth edge.

T-type Knife

T-type cutter is a tool installed on the milling machine for milling T-shaped grooves and side grooves of workpieces. T-type cutter is also called T-type milling cutter, semicircular milling cutter, keyway milling cutter, which can perfectly process T-shaped grooves and side grooves. It can maintain cutting performance normally at high temperatures.

Materials that can be milled include die steel, cast iron, carbon steel, alloy steel, tool steel, and general iron.

Gear Milling Cutter

Gear milling cutter is a kind of gear cutting tool that works by profiling method or non-instant center enveloping method. According to the different shapes, it can be divided into disc gear milling cutter and finger gear milling cutter. It is used to mill various tooth shapes, such as gears.

Rough Leather Milling Cutter

Roughing milling cutter is a rotary tool with one or more teeth used for rough milling. It is suitable for rough machining. It has good chip removal performance and large chip removal capacity. It has a high metal removal rate. It is mostly used for groove processing, woodworking milling cutter, and step surface processing. The groove of M42 high-speed steel roughing milling cutter is fully ground, smooth, with good chip removal performance, high hardness and high precision.

The above are the 8 most commonly used CNC milling cutters in CNC machining workshops. So, in addition to these, what other types of milling cutters do you know?