If you want to buy CNC milling tools, you need to consider many aspects, including the characteristics of the tools itself, processing requirements, and brand services. This article shares what you need to know when buying CNC milling tools.

Milling Tool Material

High-speed steel: good toughness, low cost, suitable for processing materials with lower hardness, such as aluminum alloy, copper alloy, etc., and can also be used for rough processing of steel parts with low precision requirements.

Cemented carbide: high hardness, good wear resistance, strong hot hardness, often used for processing materials with higher hardness, such as alloy steel, hardened steel, etc., can adapt to high-speed cutting, and is widely used in CNC machining.

Types of CNC Milling Tools

Face milling tools: used for machining planes. The machine power and workpiece size are mainly considered when selecting. The diameter can generally be selected as 1.5 times the spindle diameter. In mass production, it can also be selected as 1.6 times the workpiece cutting width.

End milling tools: can be used to process bosses, grooves, etc. The diameter selection should consider the workpiece size and machine power. For small diameter end milling tools, it is also necessary to consider whether the maximum speed of the machine tool can reach the minimum cutting speed.

Slot milling tools: used for machining grooves. Its diameter and width should be selected according to the workpiece machining size, and the cutting power should be within the allowable range of the machine tool.

Tool Specifications

Blade length and overall length: Select the appropriate blade length and overall length according to the processing depth and machine tool travel to ensure that the tool can meet the processing requirements and is within the operating range of the machine tool.

Blade diameter and shank diameter: The blade diameter must match the size of the processing part, and the shank diameter must be consistent with the machine tool spindle interface specifications.

Tool Accuracy

Manufacturing accuracy: High-precision milling tools can ensure processing accuracy and surface quality. For example, ground blades have higher dimensional accuracy than pressed blades and are suitable for fine processing.

Runout accuracy: Excessive tool runout will affect processing accuracy and tool life. You can request to test the tool’s runout accuracy when purchasing.

Cutting Data

Speed: Different materials and specifications of milling tools have different recommended speeds, which need to be selected according to machine tool performance and processing requirements.

Feed rate: It is related to the number of teeth of the tool, the sharpness of the cutting edge, etc. The feed rate for roughing and finishing is different.

Cutting depth: It depends on the strength of the tool, the workpiece material and processing requirements. The cutting depth can be larger during roughing, but it should be controlled within a smaller range during finishing.

Brand and Channel

Kennametal: Founded in 1938 in the United States, it is a world-leading tool solution provider, and its carbide tools are internationally renowned.

Coromant: A brand of Sandvik, a world-leading brand of metal cutting tools and tool systems.

ISCAR: The world’s largest metal cutting tool manufacturer, with a wide range of products and advanced technology.

Offline dealers: You can see the real thing directly, communicate with sales staff conveniently, and get professional technical support and after-sales service, but the price may be relatively fixed.

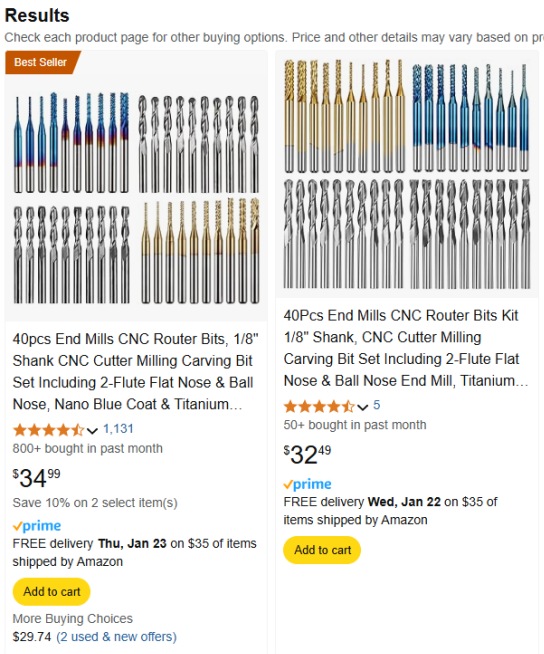

Online platforms: Professional industrial supplies procurement platforms such as Wheat Diary, the prices are relatively transparent, and there are many user reviews for reference, but you must pay attention to distinguish the authenticity and quality of the product when purchasing.

The above are things you need to know when buying CNC milling tools. I hope that after reading this article, it can help you avoid pitfalls. If you still don’t know how to buy CNC milling tools? Then bookmark this page and follow us for more content about buying CNC milling tools.