We are a company specializing in custom machined parts. We provide turning, milling, drilling, tapping, boring, laser cutting, stamping, casting and other manufacturing processes in a variety of materials to manufacture a variety of high-precision metal parts for various industries around the world. Available CNC machining materials mainly include: aluminum alloy, stainless steel, carbon steel, brass, copper, titanium, PEEK, ABS, nylon, acrylic, rubber, etc. Our professional CNC machining capabilities ensure the delivery of high-quality CNC products within the agreed time. The “Brass CNC Bottle Opener Single Finger EDC Machining” displayed on this product page is a customized non-standard product and is currently out of stock. If you need to purchase similar products, please contact us to obtain samples. Click “Contact Us” on the product page to receive free manufacturability feedback on your CNC-manufactured bottle opener. Once both parties confirm the order, you can enjoy free sample service.

Our team has been engaged in CNC machining business for more than 10 years and has rich experience in EDC CNC machining(like brass cnc bottle opener). EDC (Every Day Carry) means items that are carried with you every day. Our CNC machining services can manufacture almost any type of EDC product for you. The precision of the custom non-standard parts we process can be performed according to the customer’s requirements. Our factory can meet almost all types of OEM custom parts processing needs. Powerful 3-axis, 4-axis and 5-axis CNC machine tools can manufacture metal or plastic parts of any simple or complex structure. Send your design files to our email and receive quotes, lead times, and manufacturability feedback on real, working CNC machined parts (like a bottle opener) within hours. Our small batch production can provide you with CNC bottle opener samples quickly without the burden of large-scale orders, thus balancing cost and efficiency. In machining, you can always customize the size, tolerance, design, color and other attributes of the part. Additionally, we can use different machining processes to meet any of your surface finish requirements. We will conduct quality inspection of product quality before each shipment. Our services also offer many advantages, including cost-effectiveness, speed and versatility. We work closely with our customers to understand their needs and provide them with customized solutions that meet their specific needs. We can also provide free advice on CNC machining, as well as long-term after-sales service.

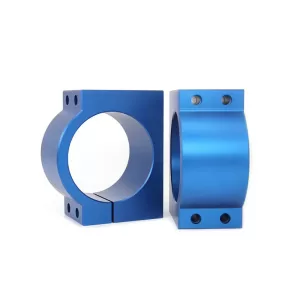

Brass CNC Bottle Opener Single Finger EDC Machining

| Weight | 1 kg |

|---|---|

| Delivery Time | About 2 Weeks |

| MOQ | 10pcs |

| Payment Method | L/C, T/T, Western Union, MoneyGram |

| Brand | OEM/ODM |