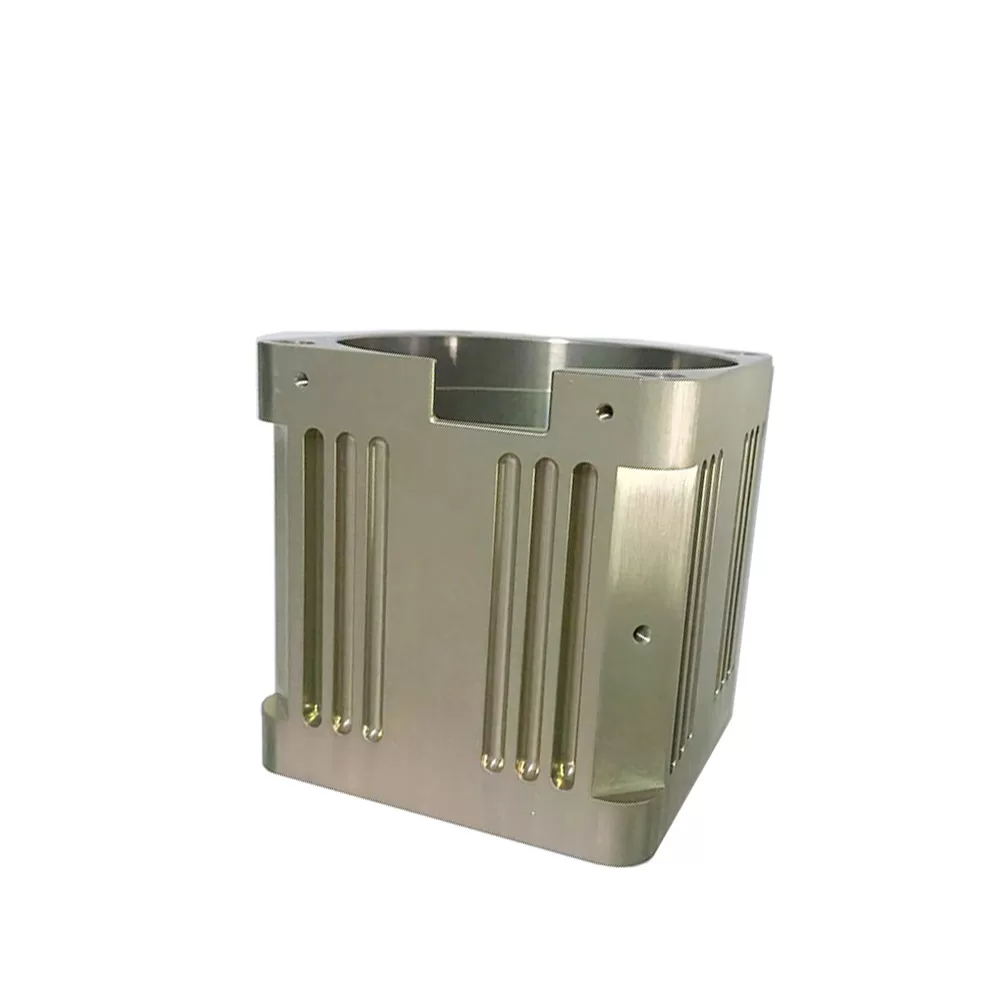

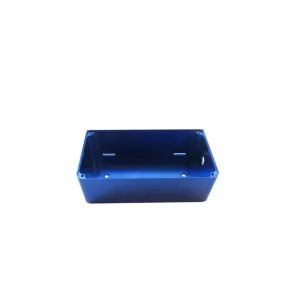

We provide CNC milling aluminum parts services to CNC parts buyers in various industries around the world. This product shows a custom-made aluminum alloy motor housing processed by a CNC milling machine. CNC milling is a precision manufacturing process that can produce parts according to your drawings in terms of appearance, accuracy, size, etc. Therefore, we can not only motor casings but also other non-standard metal parts. We are a real source factory, our machines not only have CNC milling machines but also CNC lathes, wire cutting machines, etc., so we are able to manufacture any high-precision parts. They run very fast, allowing us to deliver the part quantities you need in a timely manner to meet your production schedule. Our CNC machine shop supports OEM production, laser engraving of your brand logo, dozens of optional finishes, and more. Our advanced CNC turning and milling equipment and experienced CNC operators are waiting for your call. Just send us your samples or CAD drawings and order delivery will be completed within 15 days. Contact us for free technical support.

CNC milling is suitable for precision manufacturing and repeatable production. CNC milling is ideal for rapid prototyping and low-volume production runs. CNC mills can also handle a variety of materials from basic aluminum and plastic to more exotic materials like titanium, making them the ideal machine for almost any job. CNC milling has strong adaptability and flexibility and can process parts with particularly complex contour shapes or difficult-to-control dimensions, such as mold parts, shell parts, complex curve parts described by mathematical models, and three-dimensional space surface parts.

The aluminum material used for CNC milling is not pure aluminum, but an aluminum alloy with other metal elements added. Up to now, aluminum alloy is still the most widely used CNC machining material. In addition to the general properties of aluminum, aluminum alloys also have some specific properties of alloys due to the different types and quantities of added alloying elements. Aluminum alloy has the characteristics of low density, good mechanical properties, good processing performance, non-toxic, easy to recycle, excellent electrical conductivity, heat transfer and corrosion resistance. It is widely used in the marine industry, chemical industry, aerospace, metal packaging, transportation, etc. widely used in the field.