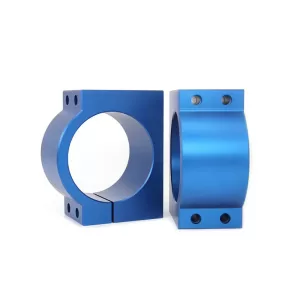

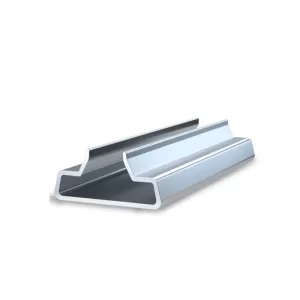

It refers to aluminum products processed by CNC turning technology according to non-standard specifications and specific requirements.

The CNC turning parts we provide you have the following features:

High degree of customization: can be manufactured in unique shapes and sizes according to different application scenarios and design requirements.

High-quality materials: high-quality aluminum materials are selected, with good mechanical properties, corrosion resistance and thermal conductivity, etc.

High precision: CNC turning technology can ensure the dimensional accuracy and surface quality of parts.

Its application fields are wide, for example:

Aerospace field: used to manufacture aircraft parts to meet the requirements of lightweight and high precision.

Automotive industry: such as engine parts, suspension system parts, etc.

Electronic equipment: such as radiators, housings, etc.

When choosing a non-standard CNC turning parts manufacturer, you should consider the following factors:

Aluminum grade and performance: choose the appropriate aluminum according to the specific use environment and mechanical requirements.

The manufacturer’s technical strength and equipment level: to ensure that the required accuracy and quality can be achieved.

In short, CNC turning plays an important role in modern manufacturing, providing reliable parts solutions for various high-end and special demand products.

Quality inspection methods

First, dimension measurement. Use high-precision measuring tools such as calipers, micrometers, and three-dimensional coordinate measuring machines to accurately measure the length, diameter, and shape tolerance of parts to ensure that they meet the design requirements.

Second, surface quality inspection. Use visual observation, a magnifying glass, or a microscope to check whether there are scratches, pits, burrs, and other defects on the surface, and evaluate the surface roughness.

Third, material performance testing, such as hardness testing and tensile testing, to verify whether the mechanical properties of aluminum meet the application requirements.

In addition, we will also perform non-destructive testing on parts, such as ultrasonic testing and eddy current testing, to detect whether there are defects inside.