The main function of best CNC machine monitoring software is to monitor the performance, production efficiency and resource analysis of CNC machine to identify and resolve errors in the process to achieve optimal efficiency. The monitoring interface usually records information such as power input, spindle speed, tool position, tool motion path, final product size, etc. In addition, CNC machine monitoring software can also perform vibration analysis, dimensional testing, power lag during processing, compatibility testing of materials and cutting tools, etc. It can also monitor tool wear, record tool movement and tool tip status, and record all events in the CNC machine through time stamps, such as tool breakage or failure, to avoid further damage to the machine. These features help optimize the performance of CNC machine, improve the overall efficiency and productivity of the equipment, and reduce the cost of replacing worn tools and lost parts, thus improving the company’s return on investment and production efficiency.

WHAT IS THE BEST CNC MACHINE MONITORING SOFTWARE IN 2023

- Predator Software: Provides technologies such as CNC networking, machine monitoring, OEE, production data management, data collection, machine simulation and verification, tool and gauge management, traveler management, CNC post-processing, flexible manufacturing systems and robotic cell control software. The software provides real-time notifications and historical analysis to help factory workers make faster, smarter, and more confident decisions based on real-time data.

- FourJaw: Provides real-time CNC machine tool monitoring software designed to provide easy-to-use and affordable solutions for the manufacturing industry. The software provides features such as real-time notifications, automated alerts, real-time dashboards, and peer-to-peer in-app messaging to increase shop floor productivity and efficiency.

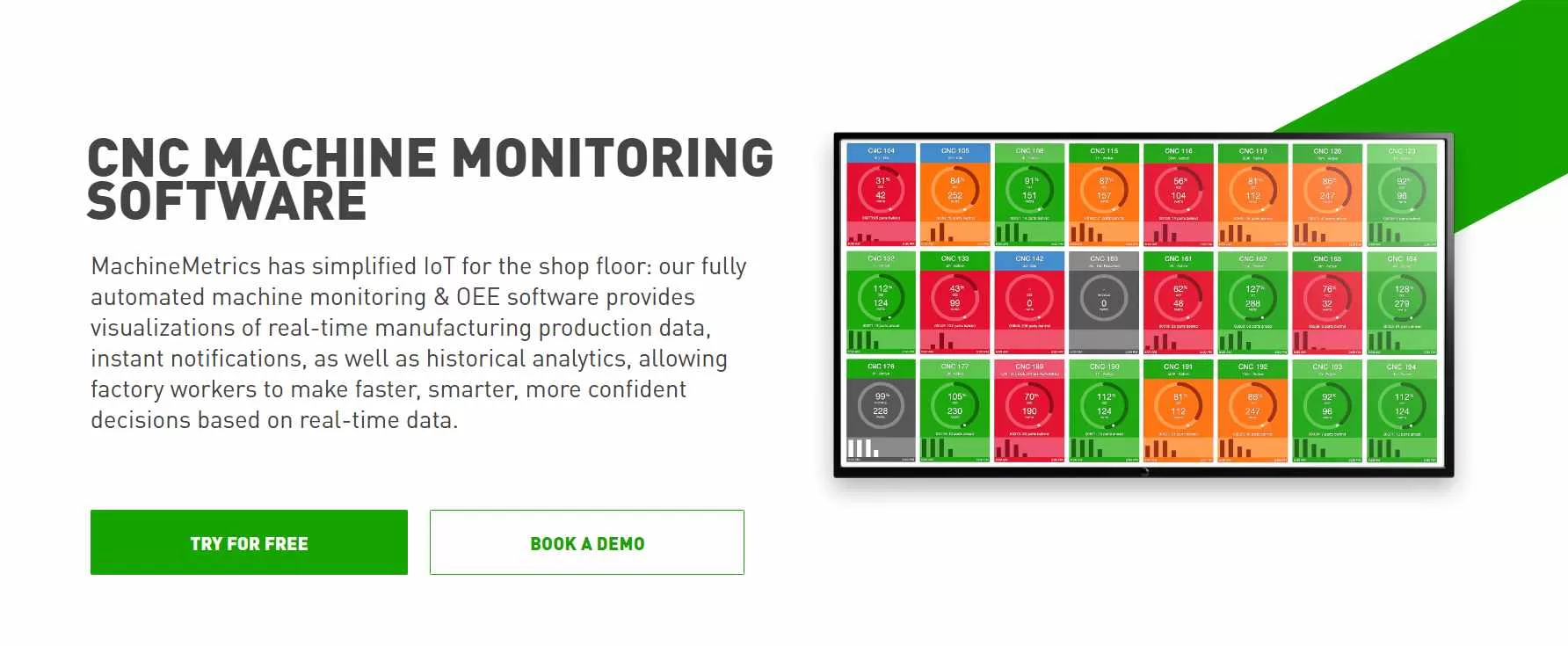

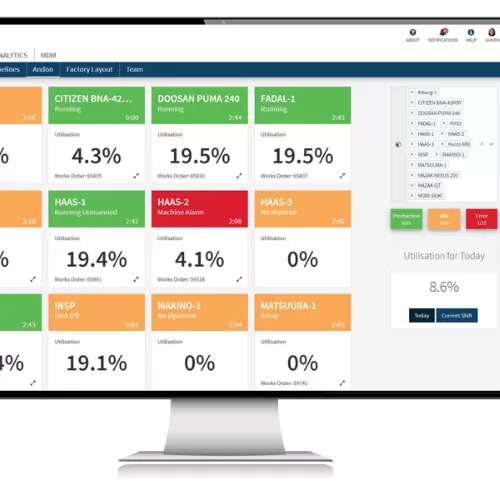

- MachineMetrics: Provides OEE and machine monitoring software, supporting multiple protocols, such as MTConnect, Fanuc, OPC-UA, UMATI, Mitsubishi, Siemens Sinumerik, etc. The software provides real-time notifications and historical analysis to help factory workers make faster, smarter, and more confident decisions based on real-time data.

Each of these software provides varying degrees of CNC machine tool monitoring and production data analysis capabilities, and specific selection should be evaluated based on the specific needs of the factory and equipment compatibility.