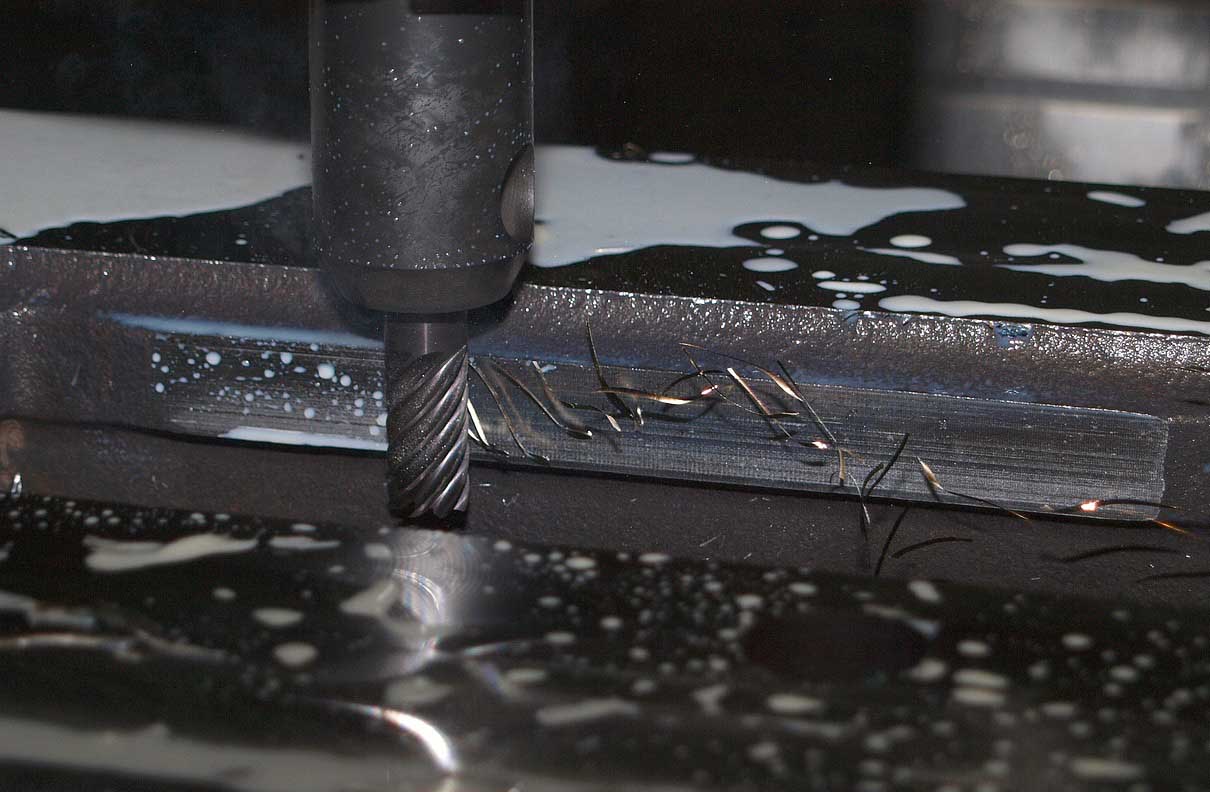

We provide high-quality CNC machining service for aluminum composite panel. We offer black, white and brushed aluminum panels and other metal panels, cut using CNC machine. CNC machine can perform cutting, grooving, sawing, drilling and other operations on aluminum composite panels, and ultimately manufacture them into products that meet customer requirements.

What Is Aluminum Composite Panel?

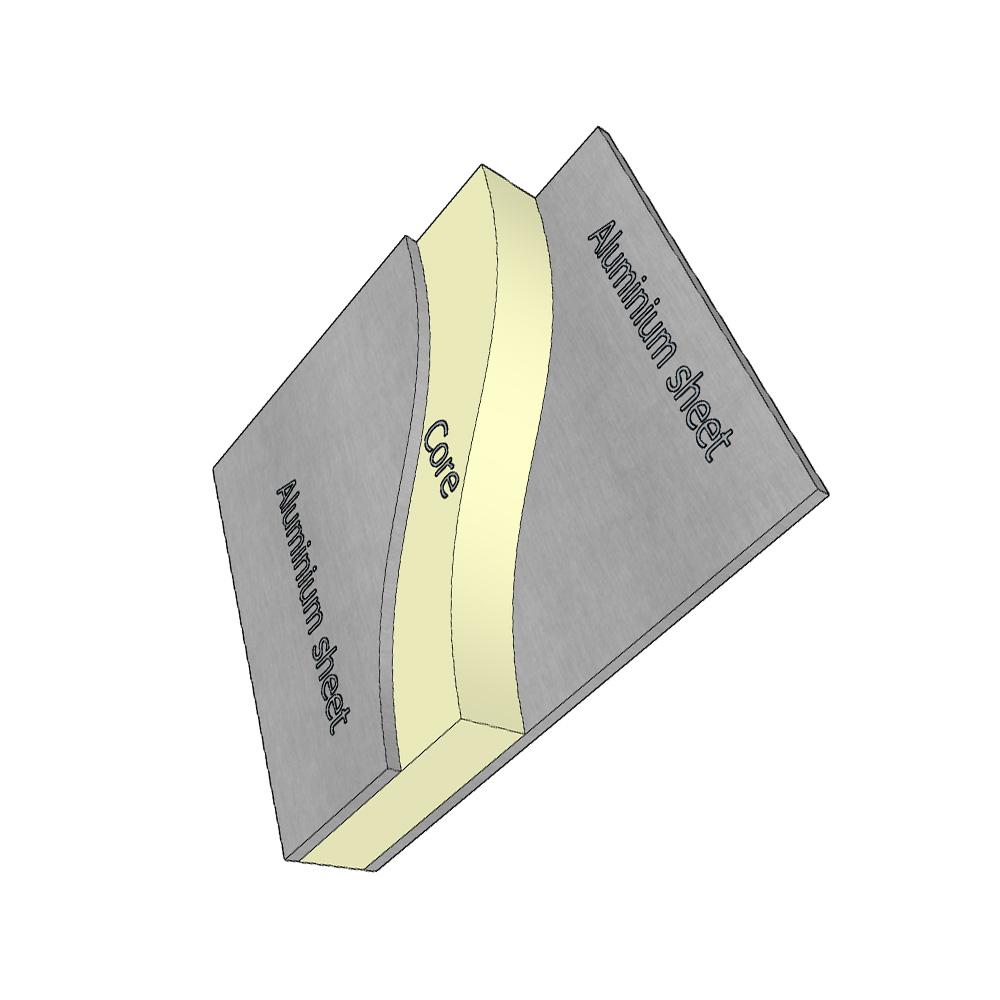

Aluminum Composite Panel (ACP) is a versatile material that is gaining popularity in various industries. It is a three-layer sandwich panel consisting of two thin layers of pre-finished aluminum bonded on either side of a polyethylene or fire-retardant core. The aluminum outer layers are coated with a durable polyester paint, and the grades are defined by the thickness of the metal surface, the type of metal used, and the coating applied to the metal surface. ACP is rigid, durable, lightweight, and aesthetically pleasing, making it suitable for a wide range of applications, including building cladding, signage, exhibition displays, and interior design. ACP is also easy to cut and shape, making it ideal for CNC machining. However, it is important to note that the combustibility of ACP depends on the core material and how it is laminated to the aluminum. Therefore, it is crucial to choose the right type of ACP for the intended application to ensure safety and compliance with building codes.

The Price of ACP CNC Machining Service

The price of Aluminum Composite Panel (ACP) CNC machining depends on several factors such as panel size, design complexity, type of ACP used, and location of the service provider.

Our company provides precision CNC milling service for ACP cutting at affordable prices. If you are looking for an OEM machined aluminum parts outsourcing company, we are the best choice.

The Skills in Aluminum Composite Panel CNC Machining

- Knowledge of composite materials: CNC machinists should have a good understanding of the properties of composite materials, such as ACP, including their strength, stiffness, and thermal expansion. This knowledge is essential for selecting the right tools, feeds, and speeds for machining the material.

- CAD/CAM programming: aluminum composite panels CNC machining requires the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software to create the tool paths and generate the G-code that controls the CNC machine. Machinists should have experience in using CAD/CAM software to create accurate and efficient tool paths.

- Machining techniques: CNC machinists should be familiar with the different machining techniques used for composite panels, such as routing, drilling, and sawing. They should also have experience in using specialized tools, such as diamond-coated cutters, to achieve precise cuts and avoid delamination or damage to the material.

- Quality control: CNC machinists should have a good understanding of quality control procedures, such as measuring the thickness and flatness of the material, to ensure that the finished product meets the required specifications.

- Safety: CNC machining of composite panels can produce a large amount of dust and debris, which can be hazardous to the operator and the machine. Machinists should be trained in proper safety procedures, such as wearing personal protective equipment and using dust collection and ventilation systems, to ensure a safe working environment.

Overall, CNC machining of composite panels requires specialized skills and expertise to achieve high-quality results. It is important to work with a service provider who has experience in machining composite panels and can provide customized solutions based on the specific requirements of the project.

Want small batches of custom aluminum composite panel parts? Contact us to get a quote for CNC machining of aluminum composite panels.