CNC milling tool holders are important components used to install and clamp milling cutters on CNC milling machines and other processing equipment, and to achieve rapid tool replacement, positioning, and certain motion functions. So today, let’s learn about the types of CNC milling tool holder.

The CNC milling cutter holder is an important part of the CNC milling machine. It is used to install and fix the milling cutter and realize the automatic replacement and positioning of the tool. The following are some common types of CNC milling cutter holders:

Classification by structure

Rotary tool holder

- Vertical axis rotary tool holder: Generally, it is a square or hexagonal tool holder, which can be installed with four or six tools respectively. The structure is relatively simple and the cost is low. It is suitable for small processing plants with fewer processing procedures and less tool demand.

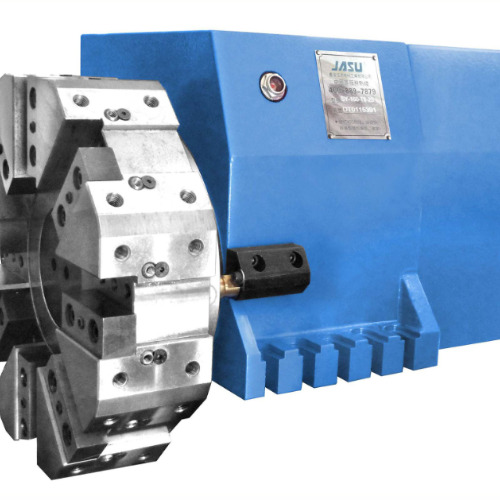

- Horizontal axis rotary tool holder: Usually a disc-type rotary tool holder, it can be installed with a large number of tools and can adapt to more complex processing technology. In one clamping, multiple tools can be switched, which reduces the tool replacement time and improves the processing efficiency. However, the structure is relatively complex and the cost is relatively high. It is often used in large CNC lathes with high requirements for processing accuracy and efficiency.

Row-type tool holder: Generally used for small-sized CNC lathes, mainly for processing bar or disc parts. Its structural form is that the tool holders holding various tools for different purposes are arranged on the horizontal slide along the X-axis direction of the machine tool. This tool holder is convenient in terms of tool arrangement and machine tool adjustment. It can arbitrarily combine various tools for different purposes according to the turning process requirements of specific workpieces.

Automatic tool changer with tool magazine: t consists of a tool magazine and a tool exchange mechanism, and is used when a large number of tools are required. It can realize the functions of large-capacity tool storage and automatic tool exchange. The number of tools placed in the tool magazine ranges from dozens to hundreds, and the time for automatic tool exchange can be shortened to a few seconds or even a few tenths of a second.

Classification by transmission mode

- Mechanical transmission tool holder: The tool is rotated and fed through mechanical devices such as gears and belts. The transmission accuracy is relatively low, but the structure is simple and the cost is low. It is suitable for some ordinary CNC milling machines that do not require high precision.

- Hydraulic transmission tool holder: The tool holder is driven by a hydraulic cylinder. It has the advantages of smooth transmission, large output, and fast response speed. However, the maintenance requirements of the hydraulic system are high, and there is a risk of leakage. It is often used in mid-to-high-end CNC milling machines.

- Electrical transmission tool holder: The tool holder is driven by a servo motor or a stepper motor. It has the advantages of high transmission accuracy, fast response speed, and flexible control. It is the mainstream transmission method of the tool holder of CNC milling machines at present and is widely used in CNC milling machines with various precision requirements.

Classification by function

- Non-powered tool holder: It is mainly used to install ordinary milling cutters. It does not have a power output function. It can only drive the tool for cutting through the rotation of the machine tool spindle. It has a simple structure and low cost. It is suitable for general milling processing occasions.

- Power tool holder: In addition to being able to install tools, it also integrates power modules, such as servo motors, hydraulic motors, etc., which can directly drive the tools to rotate or feed, and realize some complex processing technologies, such as milling threads, drilling, tapping, etc., and is often used in turning and milling composite machining centers or high-end CNC milling machines.

The tool holder provides an accurate installation position for the milling tools, ensuring that the axis of the tool maintains the correct relative position relationship with the axis of the machine tool spindle or other motion coordinate axis to ensure machining accuracy.

The above content briefly introduces cnc milling tool holder types. So what other questions do you have about CNC milling tool holder?