How to Choose a CNC Milling Tool Changer That Suits You

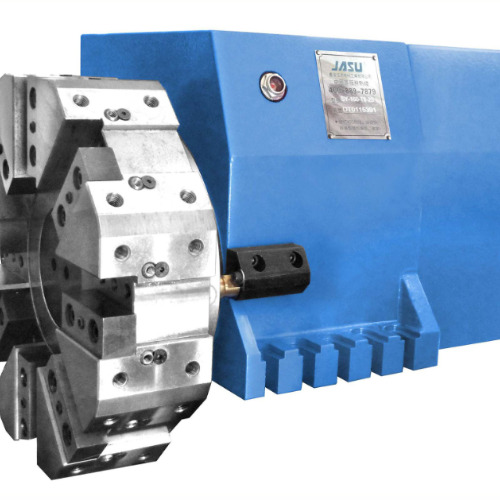

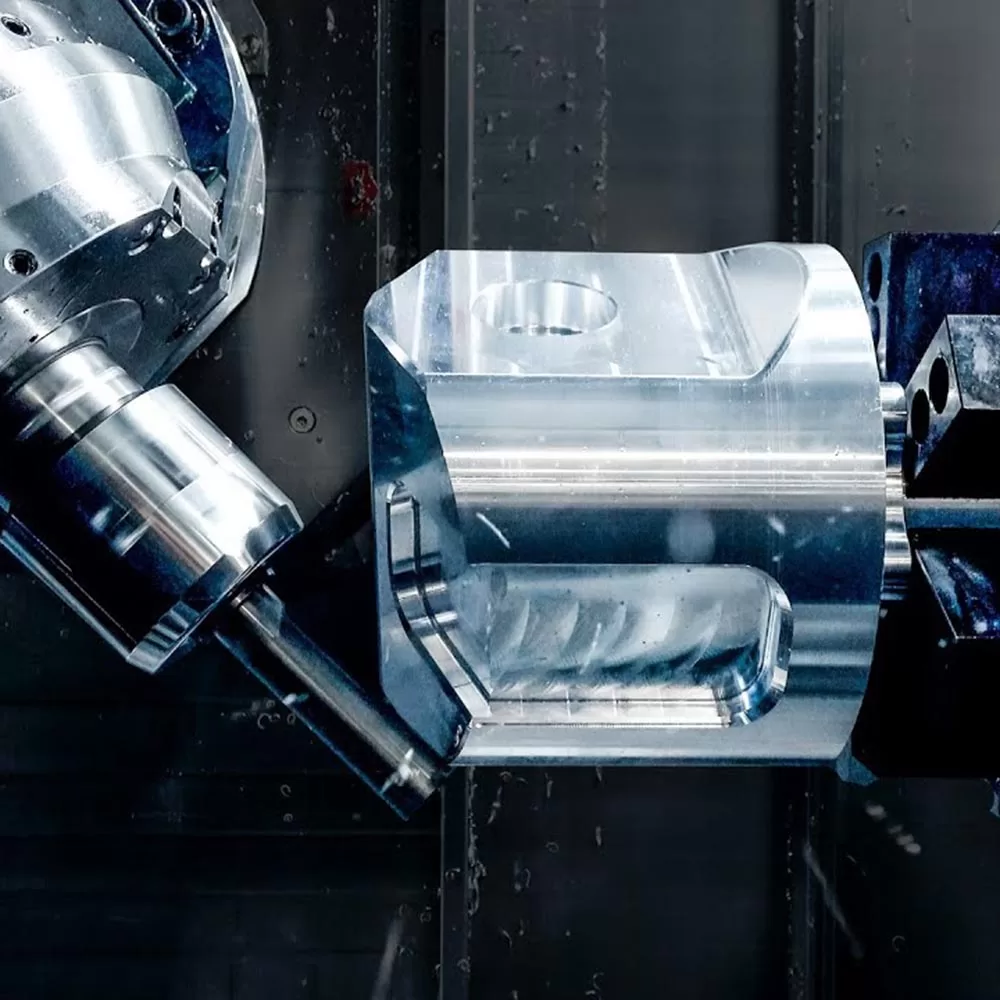

A CNC milling tool changer is a device that stores different milling tools in a tool magazine and automatically changes tools with the help of a short G code. It eliminates the need for manual tool changes for many tasks, thus shortening the machining cycle. To choose a CNC milling tool changer that suits you, […]

How to Choose a CNC Milling Tool Changer That Suits You Read More »