Let’s take a look at the applications and benefits of machining aluminum parts using precision CNC services in the aerospace (A), semiconductor (S) and medical (M) industries.

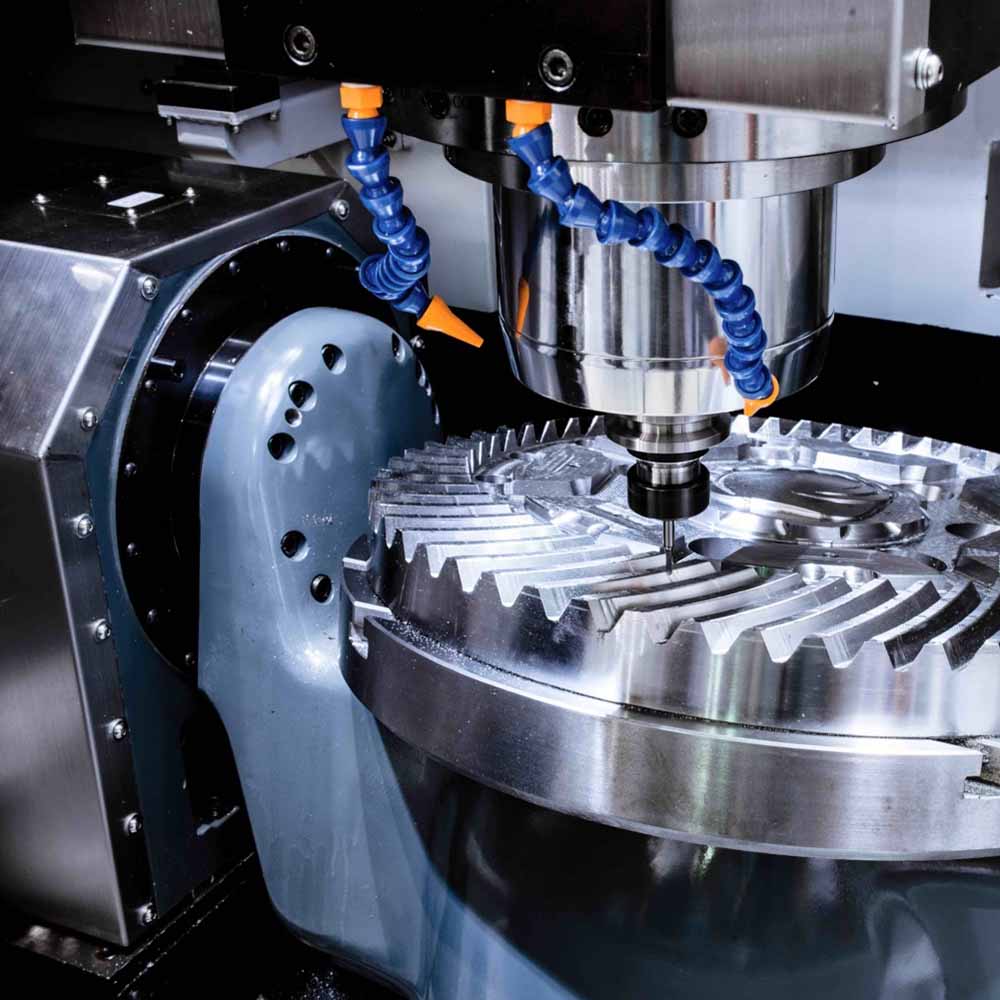

Precision CNC machining is an advanced manufacturing process that uses computerized controls to produce complex parts with high accuracy and consistency. This process involves cutting and shaping raw materials into precise components based on detailed design specifications. In this article, we will discuss precision CNC machining services for aluminum components in the aerospace, semiconductor, and medical industries.

Aerospace Precision Machining

The aerospace industry demands high-quality components with tight tolerances and strict material specifications. Aluminum is a popular material due to its lightweight, strength, and corrosion resistance. Precision CNC machining is used to manufacture critical components for aircraft engines, wings, avionics, and landing gear. The components must meet strict safety standards and performance criteria to ensure reliable operation and long service life.

Semiconductor CNC Machining

The semiconductor industry requires precise components for manufacturing wafer processing equipment, vacuum chambers, and inspection systems. Aluminum is used in many applications due to its thermal conductivity and electrical properties. Precision CNC machining is used to create intricate designs with tight tolerances for semiconductor applications. The components must be free of contaminants and defects to ensure high-quality production and yield rates.

Medical Precision Machining

The medical industry requires precision components for implantable devices, surgical tools, and diagnostic equipment. Aluminum is a biocompatible material that can be sterilized and has excellent corrosion resistance. Precision CNC machining is used to create complex shapes and features that meet strict medical device regulations. The components must be free of burrs, sharp edges, and surface defects to ensure patient safety and comfort.

Precision CNC Machining Services

Precision CNC machining services offer several benefits, including:

– High accuracy and repeatability

– Fast turnaround times

– Flexible manufacturing processes

– Scalable production capacity

– Cost-effective solutions

CNC milling service, precision prototyping machining, and precision grinding and manufacturing are some examples of precision CNC machining services. The choice of service depends on the application requirements and design specifications.

Aluminum CNC Service

Aluminum CNC service offers high-quality components that meet aerospace, semiconductor, and medical industry standards. Aluminum is a lightweight, durable, and versatile material that can be easily machined using precision CNC equipment. Aluminum CNC service provides several benefits, including:

– High-quality finishes

– Tight tolerance capabilities

– Design flexibility

– Cost-effective solutions

– Fast turnaround times

Precision CNC machining services for aluminum components are essential for many manufacturing applications. The aerospace, semiconductor, and medical industries demand high-quality components with precise tolerances, complex shapes, and strict material specifications. Precision CNC machining is an advanced manufacturing process that can create intricate designs with high accuracy and consistency. Aluminum CNC service offers a reliable and cost-effective solution for producing high-quality aluminum components that meet industry standards. When you occasionally need CNC to process precision parts, for this occasional demand, you don’t want to spend time and money to invest in building your own CNC production workshop. At this time, I suggest you consider our CNC precision machining outsourcing service.