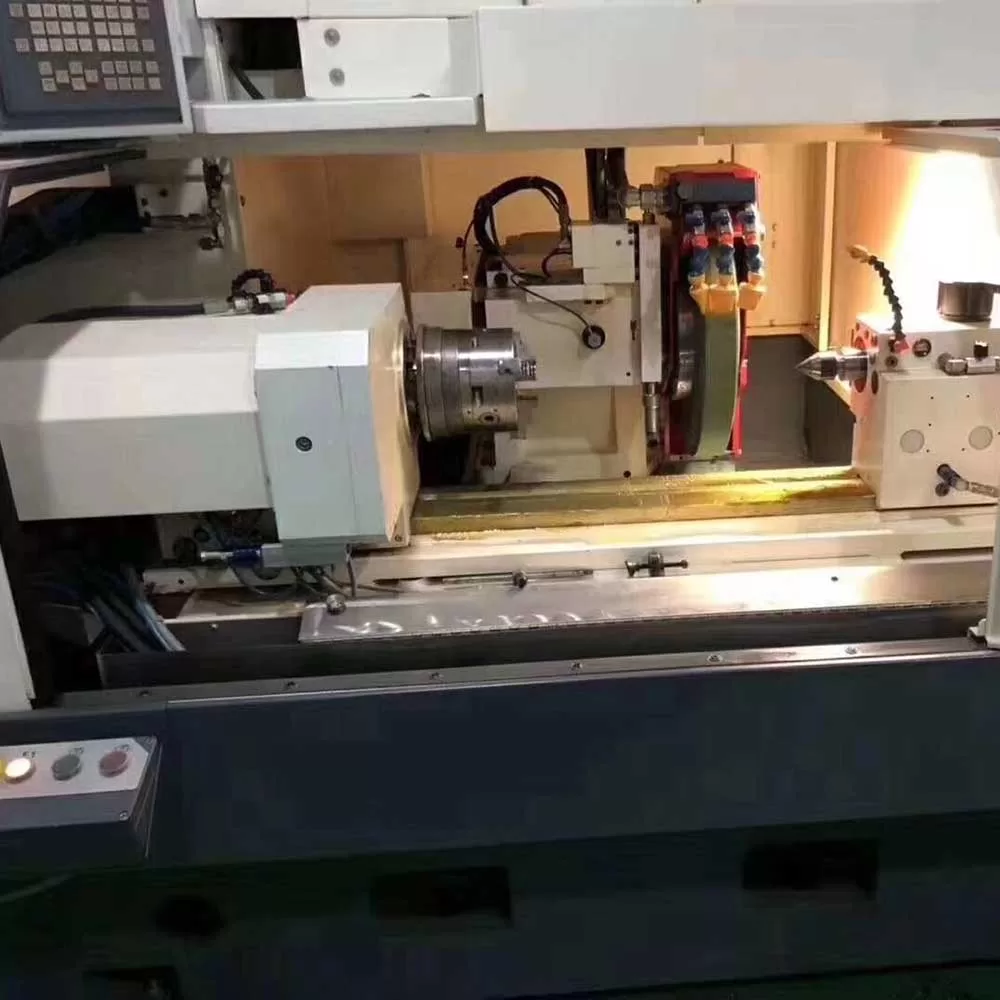

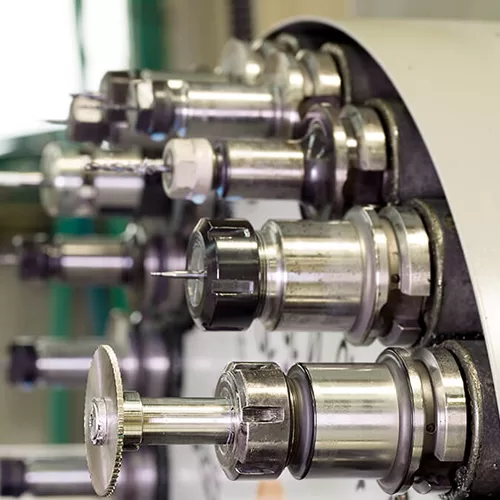

How to Machining Thread with CNC Lathe

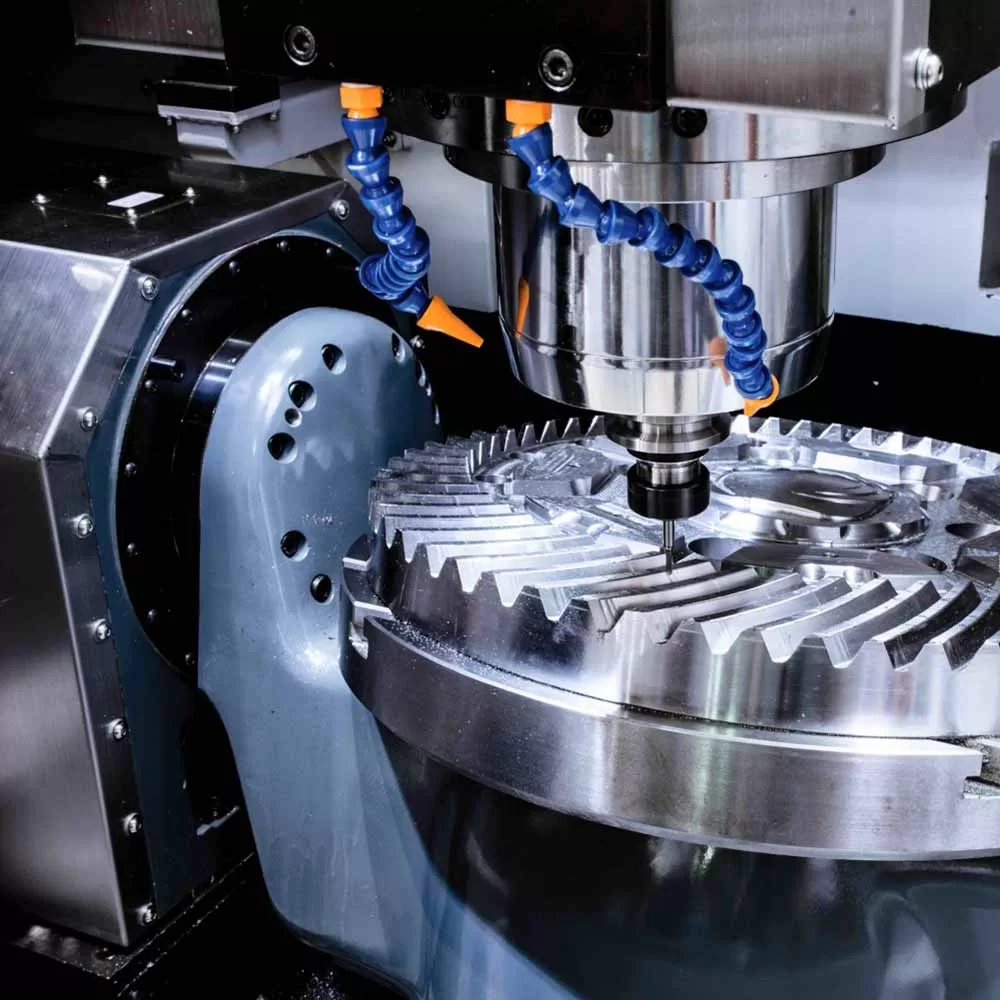

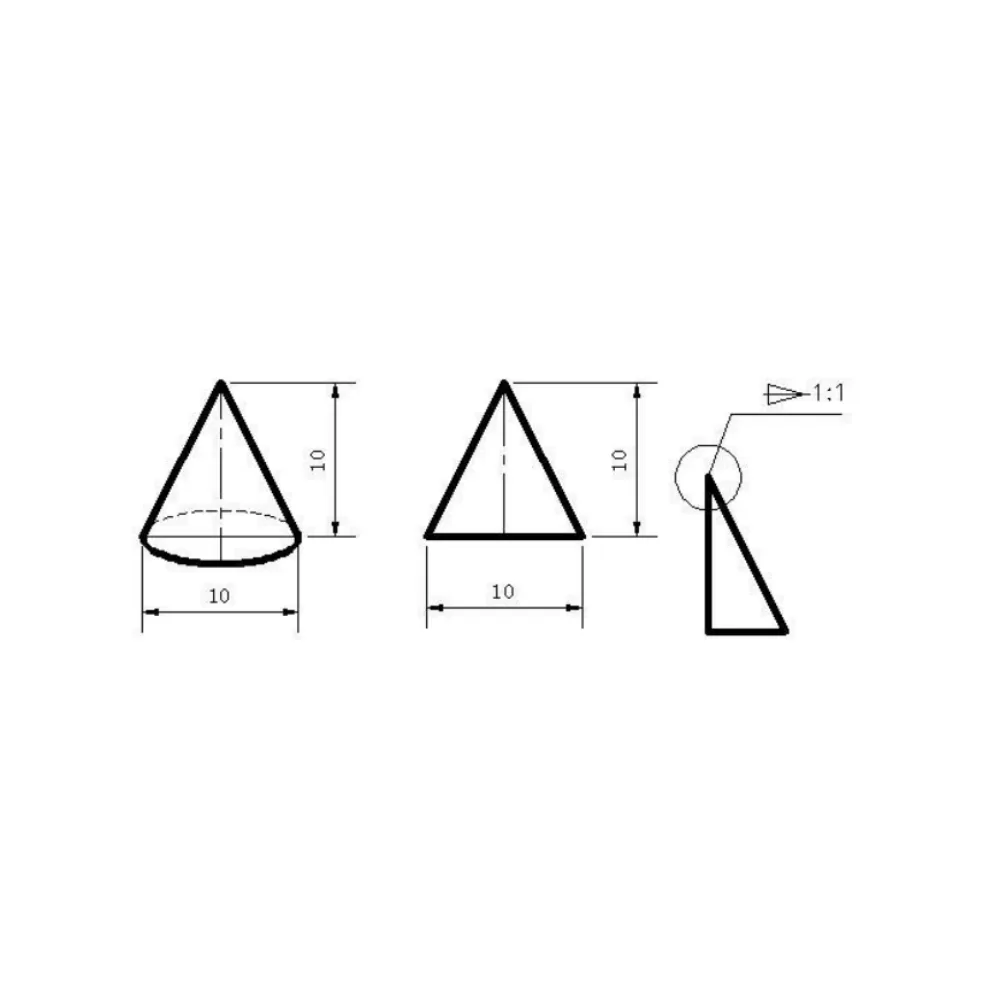

Threaded parts are widely used in mechanical products. The CNC machining technology of thread includes CNC turning, CNC milling and tapping machining and so on. CNC turning thread is actually CNC lathe machining thread. How to Machining Thread with CNC Lathe? There are generally 4 methods for machining threads on CNC lathes: straight-forward method, oblique […]

How to Machining Thread with CNC Lathe Read More »