What Is the CNC Programming Margin?

CNC programming allowance refers to a certain amount added on the basis of theoretical machining dimensions during CNC machining to ensure that the machined parts meet the required dimensions and quality requirements. The setting of CNC programming allowance has an impact on the accuracy, surface quality, machining speed, tool life, etc. of the machined parts,…

CNC Turning Stainless Steel: How to Avoid Material Waste

During the CNC turning of stainless steel, problems such as deformation, chip accumulation, and tool wear are prone to occur, resulting in a large amount of material waste. So, how to avoid the problem of material waste during stainless steel CNC turning? Read the article for the best CNC stainless steel turning methods. In the…

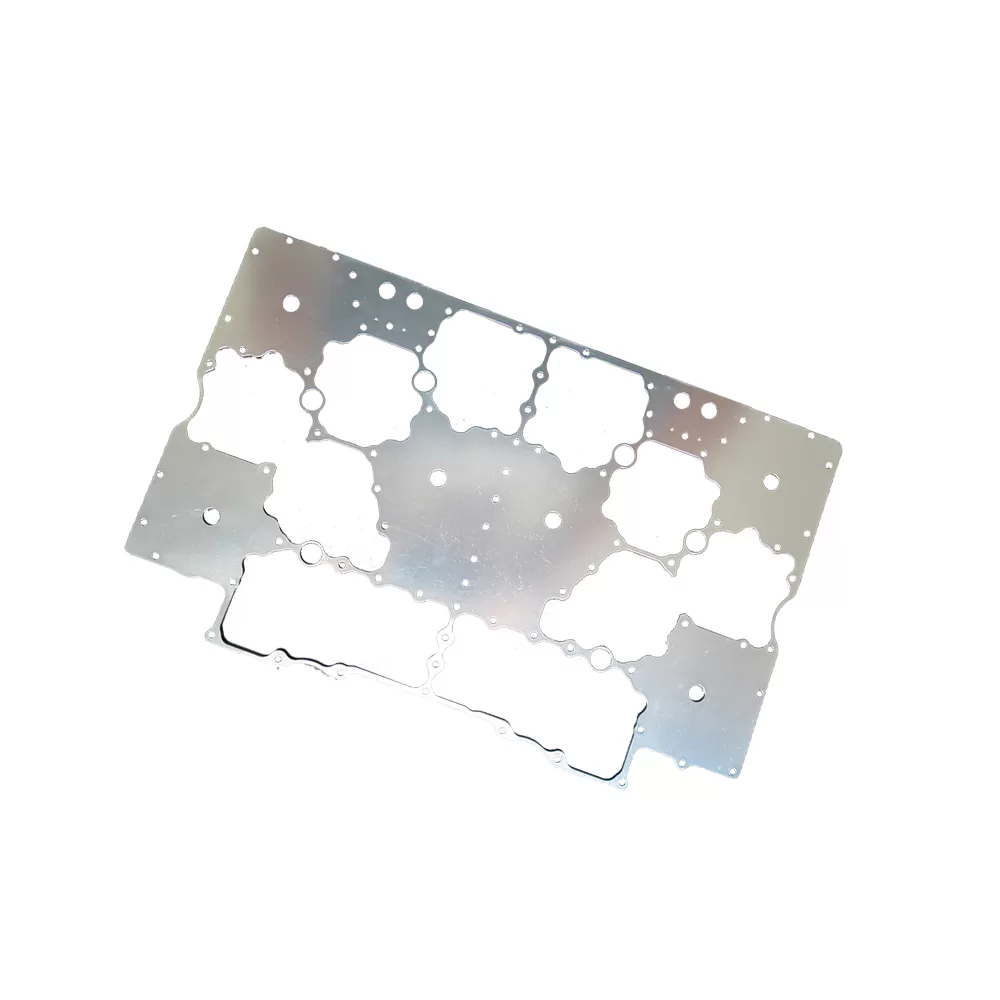

CNC Milling of Large Thin Plate Parts

CNC milling of thin plate parts has problems such as low stiffness and poor processing technology. Under the action of cutting force, clamping force, cutting chatter and other factors, processing deformation is prone to occur, and it is difficult to control processing accuracy and improve processing efficiency. Processing deformation and processing efficiency issues have become…

Leave Me a Message!

Related Categories

Related Links

- About us

- ABS CNC Machining – Non-standard Parts Manufacturer

- Alloy CNC Machining Services

- Aluminum – The Most Widely Used Metal Precision Manufacturing Material

- Aluminum CNC Turning Parts

- As Machined Surface

- Austin CNC Machining Parts Manufacturer

- Brass for CNC Machining

- Buy Cheap CNC Parts Online Support OEM Custom

- CNC Auto Service

- CNC Carbon Fiber Cutting Service

- CNC Lathe Machining Service

- CNC Links

- CNC Machine

- CNC Machine Material List

- CNC Machining Brass Parts

- CNC Machining Center

- CNC Machining Copper Parts

- CNC Machining Materials

- CNC Machining Services

- CNC Machining Services for United States

- CNC Machining Services Sydney

- CNC Machining Stainless Steel Parts

- CNC Machining Steel Fabrication

- CNC Machining Titanium Alloy Parts

- CNC Machining Tolerance

- CNC Machining Videos Free Download

- CNC Mill Lathe Combo Machining

- CNC Milling Carbon Fiber

- CNC Milling Machine

- CNC Milling PCB Service

- CNC Milling Services

- CNC Milling Turning Service

- CNC Part Inspection Service

- CNC Prototyping Savannah

- CNC Savannah Ga

- CNC Turning Center

- CNC Turning Parts Service Georgia

- CNC Turning Services

- CNC Turning Services for Savannah

- CNC Wire Cutting Service

- Contact us

- FAQ

- Free CNC Turning Specialist Service

- High Volume CNC Machining Service from China

- How to Tracking CNC Cargo

- Invar CNC Machining Company In China

- ISO9001 Certificate

- Metal CNC Machining Service

- Metal Material for CNC Machining

- Nylon-66 Parts CNC Machining Factory

- Plastic CNC Machining

- Plastics for CNC Machining

- Polystyrene(PS) CNC Machining Service

- Precision CNC Machining Services for Georgia

- Precision CNC Turning

- Precision Manufacturing Savannah

- Privacy Policy

- PTFE for CNC Machining

- Quality Testing Equipment For CNC Machined Parts

- Refund and Returns Policy

- Small Batch CNC Machining Customization Service

- Small Batch CNC Milling Parts: Types, Benefits and Applications

- Small Parts CNC Machining Company

- Steel for CNC Machining

- Surface Finishes for CNC Machined Parts

- Surface Treatment

- The Best CNC Motorcycle Parts Manufacturer

- The Best CNC Turned Parts Manufacturer in China

- The Best Medical CNC Machining Services

- Titanium for CNC Machining

- Wire EDM Cutting Service